1-Touch Laser Photo Switch

This switch is automatically selected when printing photos from Universal Laser Systems 1-touch

Photo laser photo printing software. This switch also be selected when printing a photo processed by

1-Touch Photo and then imported into other software before printing. This switch optimizes settings

for best results with 1-Touch Photo images.

Image Density

The Image Density setting determines how many lines of pixels (or dots) per vertical inch are used to

render a raster image on the material being laser marked or engraved. It can also be referred to as the

vertical resolution or dpi of the image. There are seven image density choices available in most models

(two extra density levels are available in SuperSpeed models). Higher Image Density (DPI) settings

produce better quality raster images with finer detail, but reduce productivity by increasing raster

engraving time. Lower Image Density (DPI) settings produce lower quality raster images, but increase

productivity by decreasing raster engraving time.

Image Density (DPI) settings will also have an effect on vector quality and processing speeds when

vectors objects contain many curves and small segments. Higher image densities will produce finer vector

detail, but may reduce productivity and vice versa for lower image densities. By running samples on scrap

materials and tying different density settings, you can find a compromise between throughput and image

quality that is acceptable to you.

SuperSpeed (optional accessory)

If the optional SuperSpeed accessory is installed a switch will be present to turn activate the feature. This

feature uses a beam splitter to separate the laser beams from the top and bottom lasers by a controlled

amount so that they will focus, one above the other on the material processing table with a distance

between them equal to the density selected. Each laser is pulsed separately, to allow two lines of raster

data to be engraved simultaneously which will cut job completion time in half. When this switch is

activated two extra densities become available. See the accessories section for more details on operation

of the SuperSpeed.

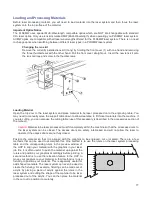

Print Direction

The default direction is Down which begins raster engraving at the top of the field and finishes at the

bottom. On some materials you may get better results by starting at the bottom and engraving towards

the top of the field (Up) due to the fact that smoke and fumes from the engraving process travel over the

surface of the material before being exhausted and can mar the previously engraved areas.

62

Summary of Contents for PLS4.75

Page 1: ...PLS User Guide PLS4 75 PLS6 75 PLS6 150D PLS6MW www ulsinc com Revision August 2012...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

Page 14: ...Tamper Proof Labels Safety Labels...

Page 15: ...ULS Fiber Laser Cartridge Labels 15...

Page 16: ......

Page 17: ...PLS4 Back View 17...

Page 18: ...PLS6 Front View 18...

Page 19: ......

Page 22: ...Chapter 3 Installation 22...

Page 40: ......

Page 48: ...Chapter 4 Operation 48...

Page 83: ...Chapter 5 Accessories 83...

Page 99: ...Example Connection for PNP mode Example Connection for NPN mode 99...

Page 111: ...Chapter 6 Maintenance 111...

Page 119: ...www ulsinc com...