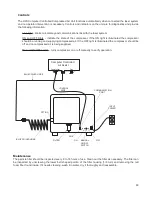

travels through a flow control device (7) which adjusts its flow in increments of 25%, 50%, 75% or 100% and

finally to the cone or backsweep. The flow control device (7) can be adjusted through the printer driver

settings. The cone path protects the focus lens (8) and provides a downward flow directly into the beam path

at the focus point of the laser beam. You choose which source (Gas or Air) (5 or 6) to use through the printer

drivers’ settings. If you choose to use a gas to supply the cone, the supply must go through the GAS coupling

(9).

As the diagram indicates, the optics protection path is not regulated nor solenoid valve controlled. So when

the ULS computer Controlled Compressed Air Unit is on air will always flow to the optics to reduce

contamination.

When the ULS computer Controlled Compressed Air Unit is in auto mode and you press the “Start” button on

the laser system, the Air Assist control box will turn ON the ULS computer Controlled Compressed Air Unit

and will keep the ULS computer Controlled Compressed Air Unit ON until the file completes.

The control box also has built in pressure sensors that will detect insufficient supply pressure and will stop

laser processing. An error message, “The air pressure is low or unstable” will appear on the computer

monitor, indicating that there is a problem with your supply of air or gas.

Air Flow Setting Guidelines

As a rule of thumb the flow rate should be set as low as possible for the application especially when using

gas. Start with low flow and adjust upward until the desired result is achieved, such as suppression of flame

up.

Maintenance

The components of the computer controlled air assist are maintenance free. However, use of air assist may

cause the interior of the laser system to become dirty faster. Keep you laser system clean for best

performance.

Air Assist Back Sweep

The Air Assist Back Sweep directs debris and smoke away from cutting or engraving process toward the exhaust

at the back of the laser system. When using the air assist back sweep, you can adjust the angle of the air jet

coming from the back sweep as necessary to optimize the effect of the air assist.

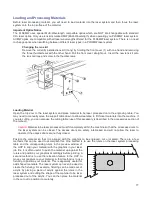

1. To install the back sweep remove the thumbscrew that seals the air assist feed port for the

backsweep.

2. Insert the air assist back sweep’s brass tube into the forward of the two holes on the carriage.

86

Summary of Contents for PLS4.75

Page 1: ...PLS User Guide PLS4 75 PLS6 75 PLS6 150D PLS6MW www ulsinc com Revision August 2012...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

Page 14: ...Tamper Proof Labels Safety Labels...

Page 15: ...ULS Fiber Laser Cartridge Labels 15...

Page 16: ......

Page 17: ...PLS4 Back View 17...

Page 18: ...PLS6 Front View 18...

Page 19: ......

Page 22: ...Chapter 3 Installation 22...

Page 40: ......

Page 48: ...Chapter 4 Operation 48...

Page 83: ...Chapter 5 Accessories 83...

Page 99: ...Example Connection for PNP mode Example Connection for NPN mode 99...

Page 111: ...Chapter 6 Maintenance 111...

Page 119: ...www ulsinc com...