BASIC MAINTENANCE

Section 4-6

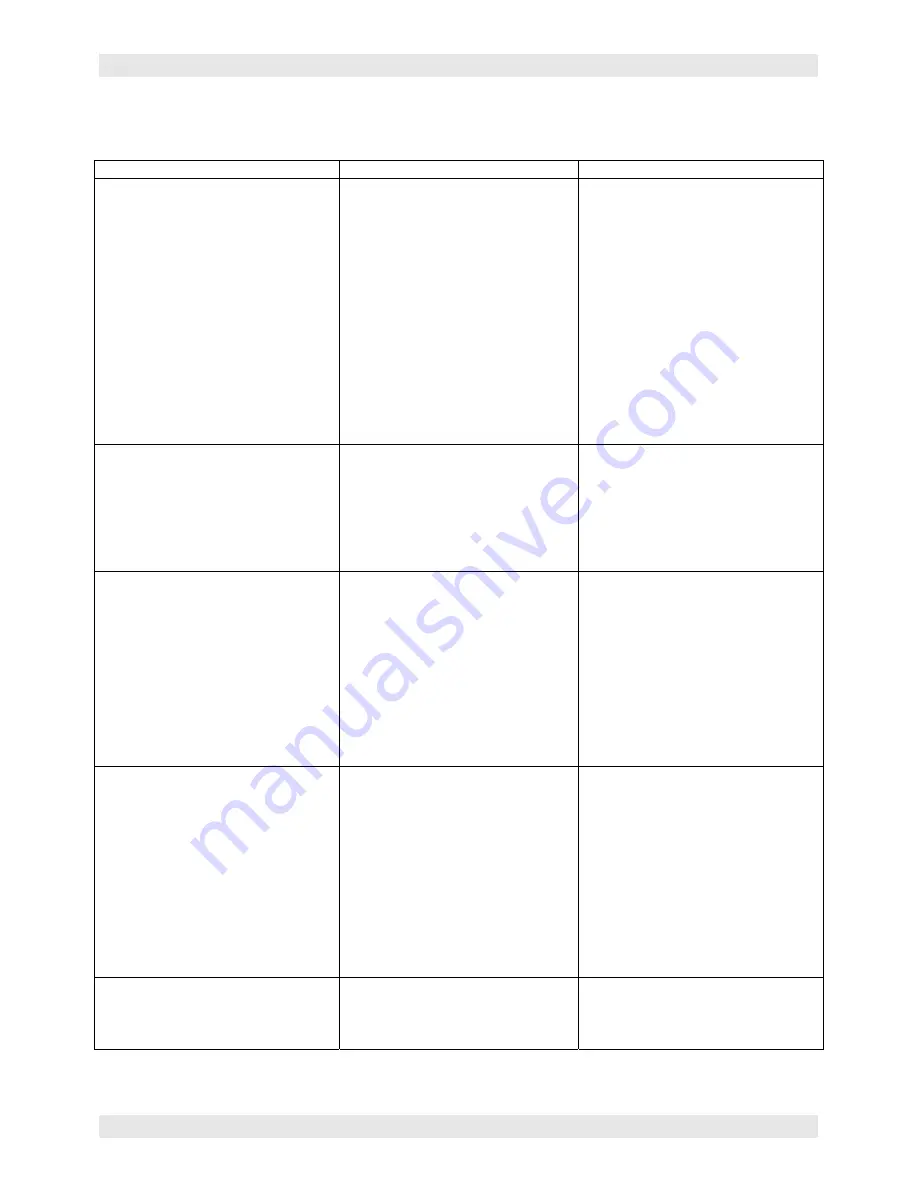

Troubleshooting Guide

Engraving Quality

Problem

Possible Cause

Possible Solution

“Fuzzy” looking raster engraving or small

text appears like a “double image”

•

Dirty laser system

•

Graphic, graphic software, graphic

software setup, color palette,

monitor display colors, or driver

settings have changed

•

Speed to fast for the material

•

Out of focus

•

System needs tuning

•

Worn X-axis belt and/or drive gear

•

Laser Tube is faulty

•

Clean all optics, rails, bearings and

belts

•

Check to see what has changed.

Refer to the “Computerized

Controls” manual to properly setup

the graphics software. Check driver

settings.

•

Slow down engraving speed

•

Re-focus

•

Run “Tuning” feature in printer driver

•

Replace belt and/or drive gear, and

run “Tuning” feature

•

Replace laser tube

Fine detail is missing such as the serif’s

of characters or thin lines of script fonts

when raster engraving

•

Speed too fast for the material

•

Laser cannot respond to low duty-

cycle, high speed engraving

•

Out of focus

•

System needs tuning

•

Laser spot size too big

•

Slow down engraving speed

•

Run enhancement feature in the

printer driver

•

Re-focus

•

Run “Tuning” feature in printer driver

•

Use shorter focal length lens

Vertical or diagonal background pattern

present when raster engraving large

areas and/or large amounts of material

•

Dirty laser system

•

Slight pattern is normal

If the pattern is excessive:

•

Loose motion system components

•

Worn or damaged X-axis bearings

•

Worn or damaged X-axis rail

•

Clean all optics, rails, bearings and

belts

•

Don’t remove so much material or try

engraving shallower or deeper. Try

changing PPI and or DPI. Use a 50%

black fill to “halftone” the background

which can hide the pattern

•

Check X-axis bearings, belt, optics

•

Replace X-axis bearings

•

Replace X-axis arm

Horizontal background pattern present

when raster engraving large areas and/or

large amounts of material

•

Dirty laser system

•

Slight pattern is normal

If the pattern is excessive:

•

Laser is too cold or hot

•

Laser tube is faulty

•

Clean all optics, rails, bearings and

belts

•

Don’t remove so much material or try

engraving shallower or deeper. Try

changing PPI and or DPI. Use a 50%

black fill to “halftone” the background

which can hide the pattern

•

Check and/or clean filters

•

Make sure ambient temperature is

within specifications

•

Replace laser tube

Engraving disappears, becomes “lighter”,

or appears “choppy” when raster

engraving at high speeds within ½ inch of

Y-axis ruler

•

Normal condition. The laser system

needs to accelerate and decelerate

within this area

•

Move graphic and/or material to the

right, outside of this area

•

Slowing the raster speed down

reduces the effect

Summary of Contents for SuperSpeed-660

Page 6: ......

Page 20: ...INSTALLATION Section 2 8...

Page 34: ...SYSTEM OPERATION Section 3 14...

Page 44: ...BASIC MAINTENANCE Section 4 10...