50

4.7

THE RUBBER STAMP OPTION

There are two switches in the ULS Windows printer driver which manage the rubber stamp option, the

RUBBER STAMP

switch and the

INVERT FILL

switch. The

RUBBER

STAMP

selection taper

profiles the engraving and automatically mirrors the entire page about it’s centerline. The

INVERT

FILL

switch will turn the entire page into a negative while it is printing. This image inversion causes the

laser system to engrave out the background and leave the characters standing up. The

INVERT

FILL

selection is only used when engraving a full sheet of stamps because it creates the negative image for the

entire sheet, not just an individual stamp. Selecting both features allows the user to create a full sheet of

rubber stamps as a positive and unmirrored image on screen. Since there are several different methods

in creating and producing rubber stamps, we will give just a few examples to follow so that the process

becomes fully understandable. Experiment with the different techniques and choose the method most

desired.

To create the artwork and engrave only one or a few stamps, set the page size in the graphics program

to something smaller than the full field. Just as an example, we will use a page size that is 8.5 x 11

inches in the Landscape mode. In this way we can output to a paper printer, before engraving, for

proofreading. Do not use the full 17 x 11.5 inch size for one or a couple of stamps because printing

time will be longer. Make sure that this page size is set up the same in the ULS Windows printer driver.

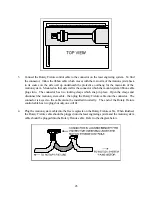

Draw a black box slightly larger than the size of the stamp desired. Type in or add graphics within that

area and color them with a fill of white. It is not necessary to mirror the image. Then draw a red outline

box (.001” line thickness) for the cut. An example is shown below.

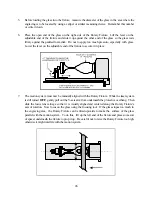

Since the driver automatically mirrors the entire page when the

RUBBER

STAMP

option is selected,

be aware that the stamp will engrave on the opposite side of the page. As an example, position the

stamp in the upper right hand corner of the page and place a full sheet of rubber in the upper left side of

the engraving area inside the laser system. We recommend installing the High Resolution lens for

engraving rubber stamps. Focus on the material using the correct focusing tool and go to the ULS

Windows printer driver to set the power settings. There are some sample settings in section 4.8 of this

manual for rubber stamps. They might have to be adjusted for different types of rubber and

thicknesses. When selecting

RUBBER

STAMP

in the driver, notice that the

INVERT

FILL

switch

automatically becomes selected. Deselect the

INVERT

FILL

option because it will not be used in this

Summary of Contents for ULS-25

Page 3: ...3 APPENDIX E SOFTWARE ANOMALIES E...

Page 14: ...14 Sample Exhaust System Layouts...

Page 62: ...62...

Page 82: ...A APPENDIX A WARRANTY...