13

If an error occurs, the indicator will blink. It displays errors both in commands and in

communication protocol with the host computer. Normally this indicator is on and not blinking

when power to the laser is on.

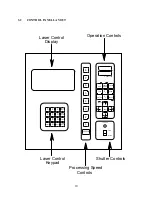

X-Y COORDINATE DISPLAY

Y POSITION

X POSITION

This displays the position of the focusing optics carriage in millimeters from the extreme lower

left of the current engraving field.

AUX. KEY AND LED

AUX

Not used - Aux. Key may light when PAUSE or REPEAT MODE are used.

TEST KEY

TEST

Used to manually turn the laser power on and off. This key is used to perform beam alignments,

power tests, tickle setting and to manually mark origins (with arrow keys), etc. A dot will appear

to the right of the pulse mode character in the laser control display when the laser is on (See

section 3.6 for details).

3.4

SHUTTER COTROLS

The shutter controls are used to open and close the mechanical solenoid driven shutter which

blocks the beam and stops it from entering the engraving area. The switch will provide power to

open and close the shutter and the LED will glow when the shutter switch is in the open position.

If any interlocked doors are open, the shutter will close to block the beam regardless of the

position of shutter control switch.

OTE:

The LED indicates only whether the shutter switch has been set to open or closed.

It does not indicate the physical position of the shutter itself.

3.5

PROCESSIG SPEED COTROLS

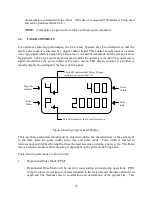

ULS Laser Systems are capable of beam positioning at a maximum speed of 420 mm/sec and this

is the default speed selected when the laser systems is powered on . However, for optimum laser

processing performance processing speed can be adjusted. The proper processing speed will be

dependent on the material being used, the type of engraving or cutting being performed, and the

depth of material removal required.

There are two methods for adjusting the processing speed: