18

See Appendix C for suggested laser control parameters for several common materials.

CAUTIO:

The laser control parameters and speed of processing all effect the final results. It

is recommended that experimentation be done on a trial piece of material until

desirable results are obtained.

3.7

SOFTWARE COTROLLED POWER CHAGE (optional)

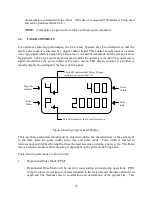

The ULS Laser Engraving Systems have the optional ability to accept software commands to

change power settings before and during engraving, which comes from the fact that the laser

systems emulate an HP-GL plotting device. This ability is best understood by an analogy to a

plotting device. The program numbers mentioned in section 3.6 can be thought of as pen

numbers and when a color in a software package is assigned a pen number that color will be

engraved using the Pulse settings stored in the corresponding program number. Once the power

settings have been stored in programs as described in section 3.6, accessing a power setting using

software is only a matter of assigning the appropriate color to a particular portion of a drawing.

The color/pen number combinations vary from software package to software package and it is

best to consult your software manual to find out which colors correspond to which pen numbers

in a particular piece of software. Many software packages also give the user the ability to assign

a color or several colors to a pen. If Microsoft Windows is being used, the color pen/number

combinations are found in the ULS Windows Printer Driver. Use of the driver is explained in the

documentation which accompanied it. (This driver is required if Windows is being used and can

be purchased from ULS.)

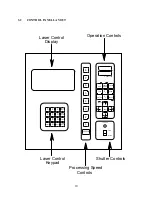

The power change option can be turned on and off by pressing a sequence of keys. If the option

is turned of the machine will operate in manual mode as described in section 3.6. To turn the

option on, press in sequence the 0 and 8 keys and to turn the option off, press in sequence the 0

and 9 keys. A dot will appear on the display to the right of the program number to indicate that

the option is turned on.

3.8

FOCUSIG PROCEDURE

Laser Processing should be done with the laser beam focused on the top surface of the work

piece. The focal length of standard optics, provided with the system, is 2.5 inches. To find the

proper focus position for the work piece, measure the thickness of the work piece with a

micrometer and dial the Z axis crank knob to this same thickness. The numbers near the dial

indicate X axis movements in one thousandths (0.001 inch) increments.