neighbor” starting point method.

2. Once open paths are completed, closed paths will follow in a nested order, beginning with closed paths that are

contained within other closed paths, with the innermost closed path executed first and ending with the

outermost closed path.

Enhance and Sort

Enhance and Sort turns on both features simultaneously.

Vector Scaling

This feature allows you to calibrate vector output size if necessary for your application. To calibrate the

system, draw a simple shape, such as a square, to a known size and print that shape as a vector object

(make sure line thickness is .001” [.0254 mm] or less). Measure the object vertically and horizontally

using a caliper or other measuring device and use the formula (desired length/measured length) to

determine the scale ratio in X and Y. Enter the result into the X-axis and Y-axis text boxes of the vector

scaling feature respectively. Keep in mind that this feature DOES NOT scale raster images. If you are

combining raster and vector images in one file, the raster image may not align with your vectors. Raster

objects cannot be scaled after printing. If it is necessary to scale raster objects, adjust their size in the

graphic application you are using.

Vector Performance

There is a tradeoff between quality of output and speed of processing when printing vectors. For longer

straight line vectors (over 1 inch [25.4 mm]) you can adjust the speed of processing in the color table until

you achieve the desired results. However, the motion system rarely achieves the selected processing

speed when processing curves and small line segments because of the constant directional changes that

occur when processing these types of vectors. Processing speed for these types of vectors is controlled

by other rules in the software. This control allows you some adjustment of processing speed of curves

and small line segments in order to achieve desired results. Using the quality setting jobs will take longer

to complete, but will improve curve and small line segment quality. Using the throughput setting will

compromise quality a bit to improve job completion time if desired.

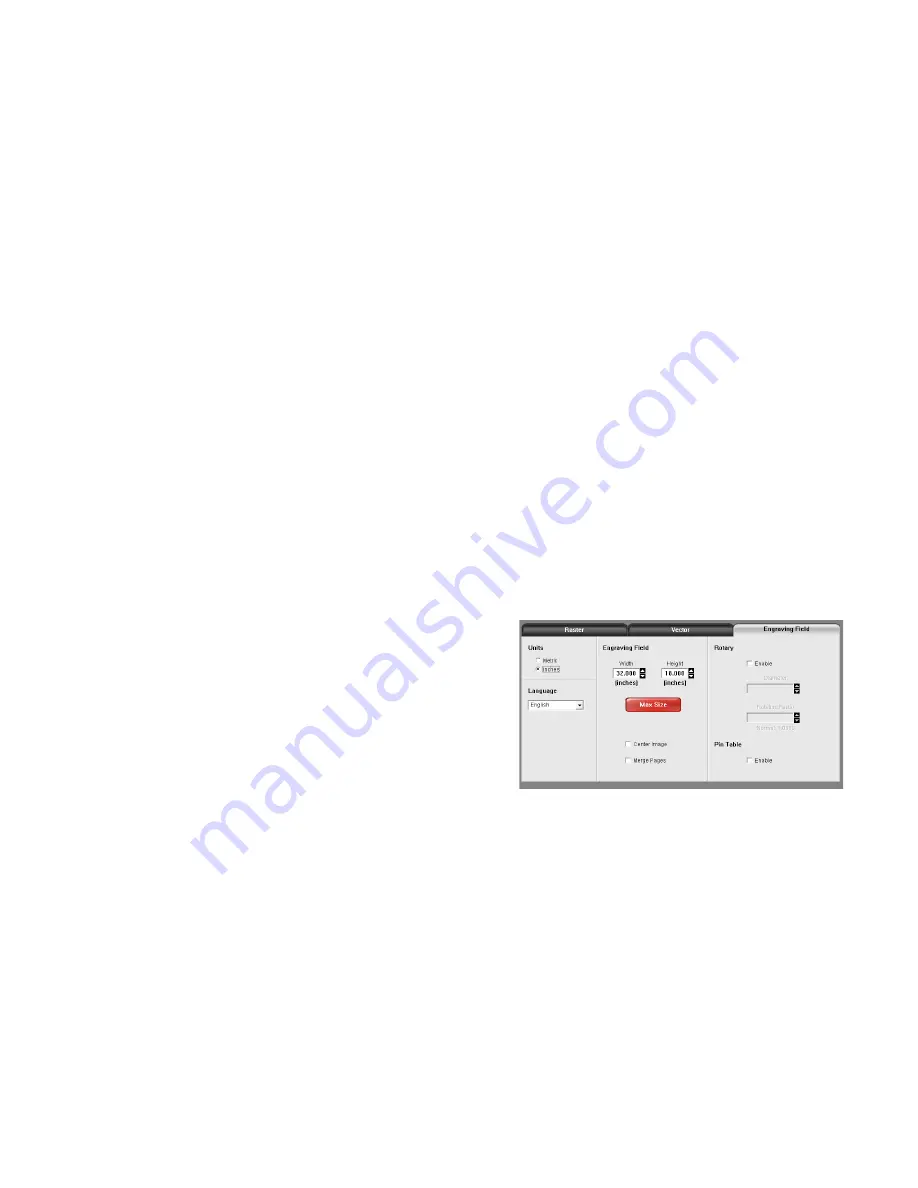

Engraving Field Sub-Tab

The engraving field sub-tab on the manual control tab of the

printer driver setting interface displays a group of settings

which affect the engraving field (page size) and other

miscellaneous settings. The controls in the sub-tab are

described below:

Units

Units allows you to change units used between Metric

and English.

Language

Select from many different languages in this drop down list. Some language changes will not take effect

until the printer control panel is closed and then re-opened.

Engraving Field Width and Height

Normally you will want to set the width and height in printer driver at their max, matching the processing

field in your laser system, and set the page size in the graphic software to match. If your graphic software

does not allow large enough page sizes to match your processing field, you can reduce this engraving

field size and your reduced page size will print in the upper left corner of the field in the laser system.

Reduced page sizes are also useful in some special cases, such as rubber stamp engraving, so you can

take advantage of the invert page feature without having to engrave the entire field of the laser system

away.

Important Note:

Make sure that the page size in your graphic program always matches the engraving

field size setup in the printer driver. Mismatched settings may cause your graphics to print in an

unexpected location or not at all.

55

Summary of Contents for VLS2.30

Page 1: ...VLS Desktop User Guide VLS2 30 VLS3 50 www ulsinc com Revision 2012 08...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

Page 9: ......

Page 15: ......

Page 16: ......

Page 19: ...Chapter 3 Installation 19...

Page 36: ...Chapter 4 Operation 36...

Page 62: ......

Page 68: ...Chapter 5 Accessories 68...

Page 80: ...Example Connection for PNP mode Example Connection for NPN mode 80...

Page 92: ...Chapter 6 Maintenance 92...

Page 99: ...www ulsinc com...