Loading and Processing Materials

Before laser processing material, you will need to load material into the laser system and then focus the laser

system onto the top surface of the material.

Loading Material

Open the top door to the laser system and place material to be laser processed onto the engraving table. You

may need to manually move the support table down to allow clearance to fit thicker materials into the machine. If

you are cutting, you can also use the cutting table (use of this accessory is described in the accessories section of

the manual).

CAUTION:

Material to be laser processed must fit completely within the machine so that the top door to the

laser system can be closed. The access door is safety interlocked and will not allow the laser to operate if the

access door is not fully closed.

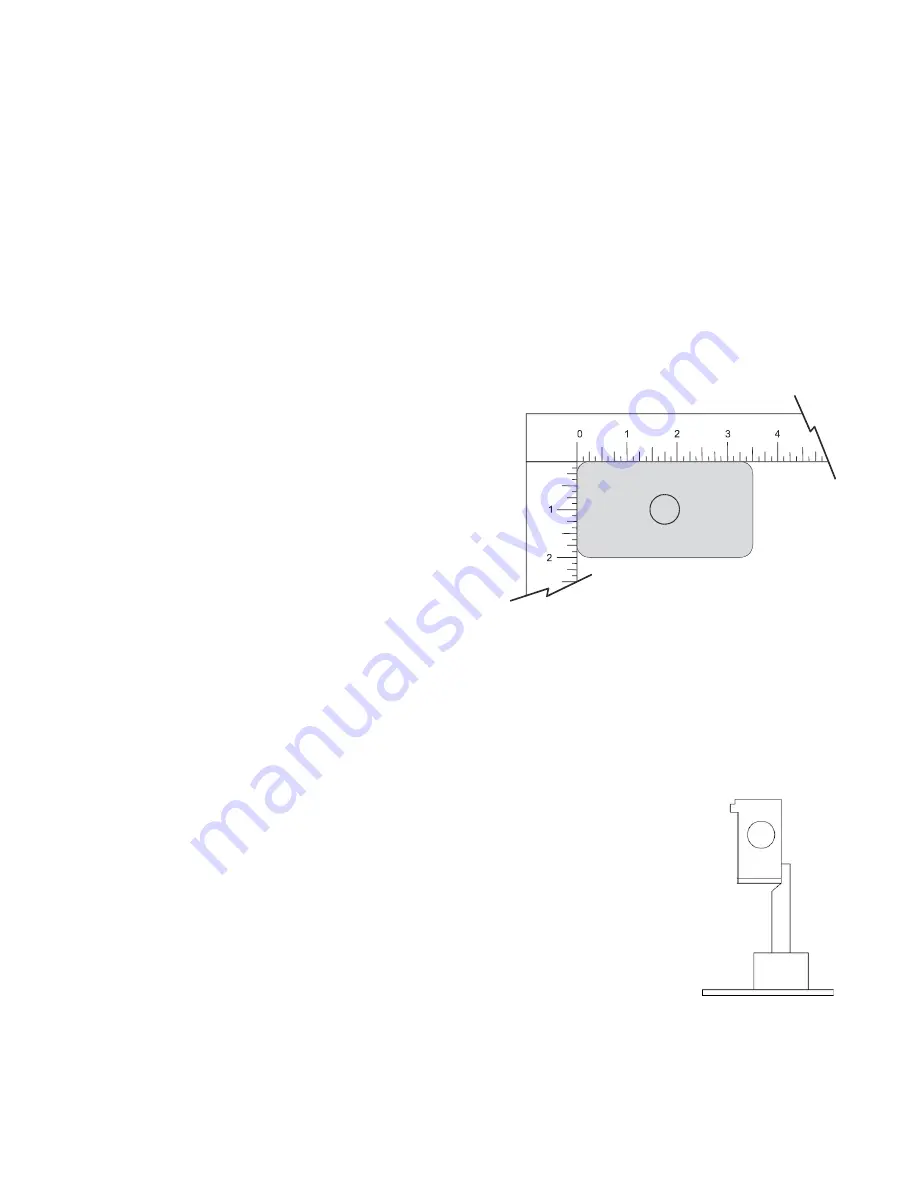

Position the material so that it is aligned with the graphics to be engraved, cut or marked. There are a few

methods that can be used to accomplish this. One method is to use the rulers on the laser system processing

table and the corresponding rulers in the preview window of

the UCP to align your material with the graphics in your laser

job file. It is often useful to push the material up against the

rulers and position your graphics accordingly before printing. A

second method is to use the relocation feature in the UCP to

move your graphics to your material. A third method is to use

fixturing to position your material. This is especially useful for

odd shaped materials. The laser system can even be used to

create the fixturing. For example, fixturing can be made out of

acrylic by placing a piece of acrylic against the rulers in the

laser system and cutting the shape of the material to be laser

processed out of the acrylic. You can then place the material

in the cut out to position it accurately.

Focusing

Once you have positioned the material, you will need to focus the laser system by adjusting the Z axis up or down

until the top surface of the material to be laser processed is at the focal plane of the lens installed in the laser

system. This can be done in one of three ways.

The first focusing method

is to use the calibrated focus tool provided with the lens kit. Every lens kit is

provided with a calibrated focus tool so make sure to use the one provided with the lens being used.

Manual focusing steps:

1. Manually move the focus carriage out over the material to be laser processed.

2.

Move the engraving table manually up or down in the Z axis as necessary until

base of the focus tool can be placed on the top surface of the material to be

laser processed and the wedge shaped notch at the top of the focus tool can

be placed as shown with the edge of the carriage fitting in the corner of the

notch.

Laser processing results are very sensitive to focus so pay close

attention to the fit of the focus tool.

3. Remove the focus tool from the material processing area.

63

Summary of Contents for VLS2.30

Page 1: ...VLS Desktop User Guide VLS2 30 VLS3 50 www ulsinc com Revision 2012 08...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

Page 9: ......

Page 15: ......

Page 16: ......

Page 19: ...Chapter 3 Installation 19...

Page 36: ...Chapter 4 Operation 36...

Page 62: ......

Page 68: ...Chapter 5 Accessories 68...

Page 80: ...Example Connection for PNP mode Example Connection for NPN mode 80...

Page 92: ...Chapter 6 Maintenance 92...

Page 99: ...www ulsinc com...