(11)

Main Moving Parts

♦

♦

♦

♦

Pistons and piston rings

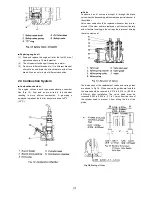

The pistons and piston rings are shown in Fig. 26. If the

cylinder liners have been bored oversize, oversize pistons

and rings must be used. The piston is made of high silicon

J-Alloy and is cam ground. The top compression ring is a

chrome plated keystone type, the second compression ring is

discontinuous and undercut and the oil control ring is of the

standard expansion type.

♦

♦

♦

♦

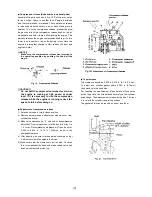

Crankshaft and connecting rod

(1) The crankshaft is a heat treated steel alloy forging. The

crank pins are induction hardened for additional wear

resistance. Crankshaft endplay is 0.006 to 0.012 in.

(0.15 to 0.31 mm).

(2) The crankpin bearings are aluminum. When installing

the connecting rods:

a) Clean both surfaces thoroughly.

b) Apply engine oil to the threads of the connecting

rod capscrews before installing and tighten each to

27 to 30.4 ft-lbs. (.3.7 to 4.2 kg-rn).

The bearing caps are matched to each connecting

rod and should not be interchanged. Also, since

there are variations in machining from side to side,

each bearing cap and connecting rod are marked

and should be assembled so that marks line up.

(3) In the event that the crankpins become worn and are no

longer serviceable, undersized hearings may be used.

When installing the undersize bearings observe the fol-

lowing precautions:

a) Machine the crankpin diameter and radii to within a

few thousandths of the correct dimensions and

finish grind to the exact dimensions.

b) After finish grinding the bearing diameter and the

radii, chamfer the diameter of the oil hole with an

oilstone. If this is not done an oil film will not form

and the bearing will seize.

c) The crankpin should always be super-finished to

0.000016 in. (0.0004 mm) or less.

d) Select the bearing from the chart that necessitates

the removal of the least amount of metal from the

crank-pin. Do not deviate from the chart

dimensions as the bearing life will be reduced if

they are machined.

e) To determine the running clearance, assemble the

connecting rod, bearing cap and bearing as

described in section 2 and measure the diameter

anywhere within the 120

o

angle indicated in Fig. 28

and subtract the crankpin diameter from this figure.

f)

The piston pin bushings are of lead bronze. The

inside diameter of the bushing should be finished

to 0.906 to 0.907 in. (23.025 to 23.040 mm).

Standard size

Over size

A

2.992 in.

(76 mm)

3.012 in.

(76.5 mm)

I

2.986 – 2.987 in.

(75.839 – 75.859 mm)

3.005 – 3.006 in.

(76.339 – 76.359 mm)

E

2.989 – 2.990 in.

(75.915 – 75.935 mm)

3.008 – 3.009 in.

(76.415 – 76.435 mm)

Over size

Name of part

Mark

0.02 in. (0.5 mm)

Piston 05

Piston ring 05

05 OS

05 OS

Cylinder liner

3.012 to 3.013 in. (76.500 to 76.519 mm)

(1.2

✙

R max. to 2

✙

R max.) by honing.

Summary of Contents for Universal diesel 5416

Page 21: ...19...