(16)

♦

♦

♦

♦

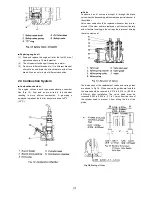

Attaching flywheel to crankshaft

Clean the entire contact surface carefully c

oat

the contact

surface with engine oi1, wash all the oil oft with gasoline and

dry it thoroughly. Put the flywheel on and torque the

capscrews to 70 to 77 ft-lbs (10 to 11 kg-m). Bend the locking

tabs back on the washers.

♦

♦

♦

♦

Tensioning of fan belt

The fan belt tension is adjusted by moving the alternator

bracket in or out. The belt is properly tensioned when the belt

deflection midway between the alternator pulley and the

crankshaft pulley is 026 to 0.35in. (7 to 9 mm) with a force of

20 lbs applied. Proper belt tension is essential for good

engine cooling and belt life. See Fig. 38.

♦

♦

♦

♦

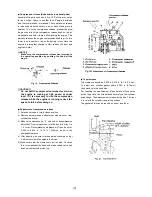

Starting Motor

The starting motor is of the standard Bendix type drive with

actuating solenoid. The assembly is shown in Fig. 43.

♦

♦

♦

♦

Cooling water pump

To install the cooling fan pulley on the pump securely

tighten the nut (4) to 50.6 to 57.9 ft-lbs. (7 to 8 kgf-m)

torque.

(1) Rust inhibitor and antifreeze should be used in

accordance with the recommendations in the

related manuals.

(2) Be sure to remove all debris that may be plugging

the fins.

(3) Check the rubber shock mount nuts periodically

to be sure they are tight.

Summary of Contents for Universal diesel 5416

Page 21: ...19...