4

IR Series

Installation, Operation, Maintenance and Parts Manual

Detroit Radiant Products Company

1.1 DESIGN

When positioning heater, keep in mind the clearance

to combustible materials, lights, sprinkler heads,

overhead doors, storage areas with stacked

materials, gas and electrical lines, parked vehicles,

cranes, etc. Refer to Figure 1.1 on page 3 for

minimum clearance to verify that a safe installation

condition exists.

In locations used for the storage of combustible

materials, signs shall be posted to specify the

maximum permissible stacking height to maintain

required clearances from the heater to the

combustibles.

1.2 LAYOUT

Perimeter mounting of these infrared heaters

provides for the most efficient installation. In Figure

1.5, the heaters are mounted around the perimeter

of the space to be heated. Refer to the Installation

Chart for the recommended distances on the models

being installed.

Buildings that require the rows of heaters to be farther

apart than the recommended distance in the

Installation Chart may need additional heaters placed

in the center of the space as in Figure 1-5.

Typical exhauster, air intake louver and thermostat

location is also shown on the sample buildings in

Figure 1.5.

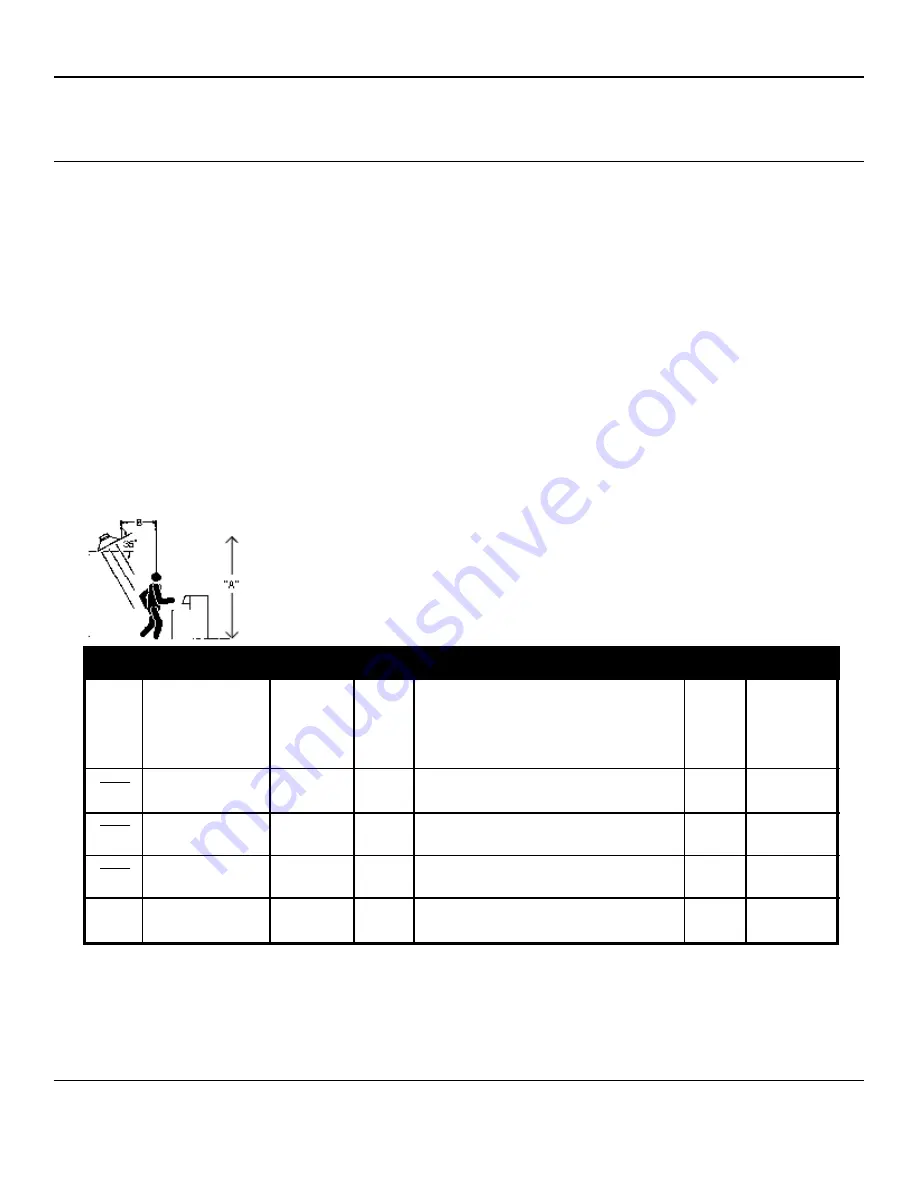

Figure 1.3

IR SERIES SPOT HEATER LOCATION CHART

MODEL

&

INPUT

IR-30

30,000

BTU/H

IR-60

60,000

BTU/H

IR-90

90,000

BTU/H

TYPE AREA

(SURROUNDINGS)

COLD/DRAFTY

AVERAGE

PROTECTED/INSUL.

COLD/DRAFTY

AVERAGE

PROTECTED/INSUL.

COLD/DRAFTY

AVERAGE

PROTECTED/INSUL.

APPROX.

DIMENSIONS

OF AREA

COVERED

10’ X 10’

12’ X 12’

14’ X 14’

16’ X 16’

18’ X 18’

20’ X 20’

20’ X 20’

24’ X 24’

28’ X 28’

APPROX.

SQ. FT.

COVERED

1 00

1 44

1 96

2 56

3 24

4 00

4 00

5 76

7 84

APPROX.

CENTERS FOR

FULL

COVERAGE

(SPOT & AREA)

HTG. ONLY

10’

12’

14’

16’

18’

20’

20’

24’

26’

’

32’

35’

“B” DIM.

DISTANCE

BEHIND

MAN OR

WORK

STATION

4 ’

5 ’

6 ’

6 ’

7 ’

8 ’

RECOMMENDED MOUNTING HEIGHT

(“A” DIM.)

10’ 12’ 14’ 16’ 18’ 20’ 22’ 24’ 26’ 28’ 30’

9 ’

10’ 12’

12’ 14’

12 14’

14’ 16’

16’ 18’

16’ 18’

18’ 20’

20’