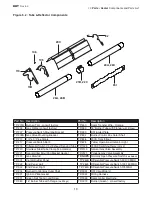

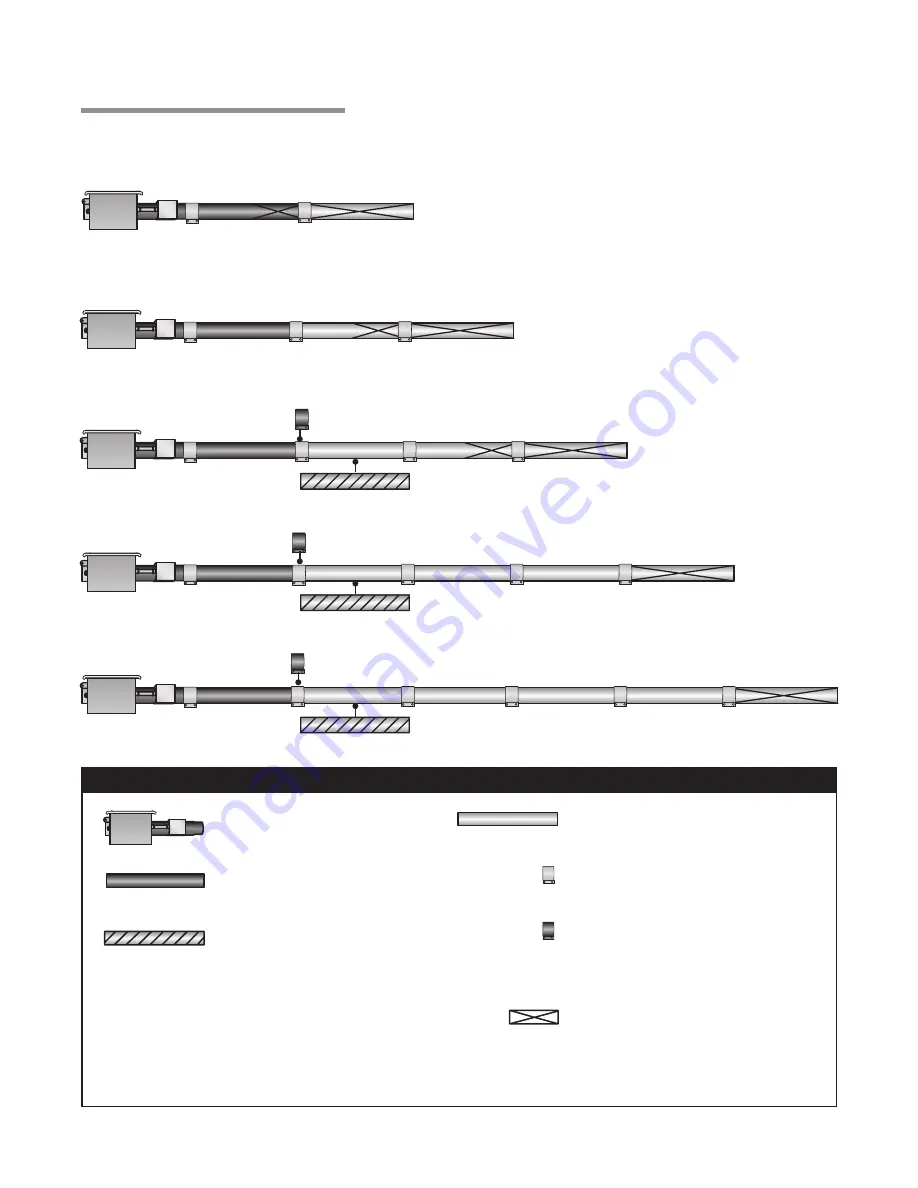

Tube Installation Sequence

11

RHT

Series

Figure 2.4

•

Tube Installation Sequence

2.0

Installation

•

Tube Sequence

•

Heater Length

Important!

The combustion chamber & radiant tube sections must be installed in the following order:

Key

*

Aluminized steel (50,000 to 125,000 BTU/H burner models), Titanium stabilized aluminized steel (150,000

to 175,000 models).

NOTE:

Refer to the Tube Heater General Manual, Chart 3.6 (page 23) for secured

reflector joints.

Standard Tube Clamp

Stainless Steel Tube

Clamp (P/N: TP-220)

175-200 MBH models only - Located

between 1st and 2nd 10 ft. tube sections.

Baffle Location

Burner Control Box with

16” Burner Tube

Primary Combustion

Chamber Tube*

Secondary Aluminized Steel

Combustion Chamber

(150-175 MBH models only)

Aluminized or Hot-rolled Steel

Radiant Emitter Tube

20 Foot

50 Foot

60 Foot

30 Foot

40 Foot

Stainless steel clamp location on 150-200 MBH models (P/N: TP-220).

Aluminized steel secondary combustion chamber location on 150-200 MBH models.

Stainless steel clamp location on 150-200 MBH models (P/N: TP-220).

Aluminized steel secondary combustion chamber location on 150-200 MBH models.

Aluminized steel secondary combustion chamber location on 150 MBH models.

Stainless steel clamp location on 150 MBH models (P/N: TP-220).