NOTICE

Connecting wires to poles without labels may interfere with the operation of the

robot.

l

Do not connect wires to poles without labels.

3.4. Robot Connection

The Robot Arm connector is next to the power supply connector. For details on connecting the

Robot Arm cable, refer to the robot user manual.

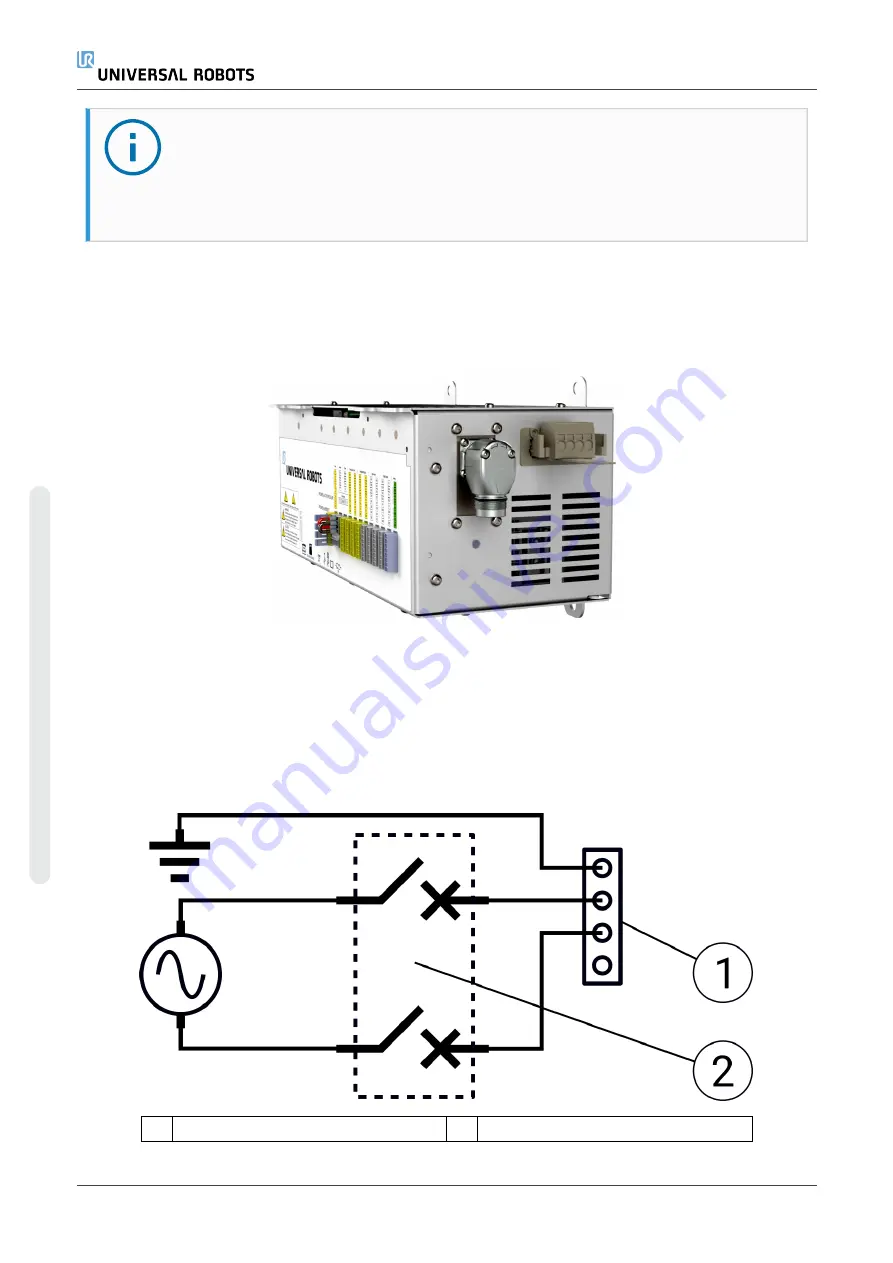

3.5. Circuit Breaker Installation

Use a double pole circuit breaker to protect the power input connector, as it can also be used as

a switch. If a fuse is used, then a two-pole switch must be installed between the fuse and power

input connector.

The following illustration shows the circuit breaker wiring scheme.

1

Power input

2

Circuit breaker

OEM Control Box

6

Installation Guide

3. Electrical Installation: AC Mains

C

o

p

yr

ig

h

t

©

2

0

1

9

b

y

U

n

iv

e

rs

a

l

R

o

b

o

ts

A

/S

.

A

ll

ri

g

h

ts

re

s

e

rv

e

d

.