FLORIDA-PNEUMATIC.COM

Please contact 1-800-356-3392 for further assistance.

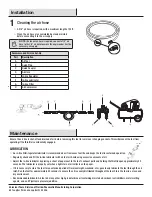

Operation

1

Operating the sander

□

This Angle Sander is designed to operate on 90 PSIG.

Lower pressure (below 90 PSIG) will reduce performance

of the tool. Higher air pressure (over 90 PSIG) raises the

performance of the tool beyond its rated capacity and

could cause serious damage to the tool and the user.

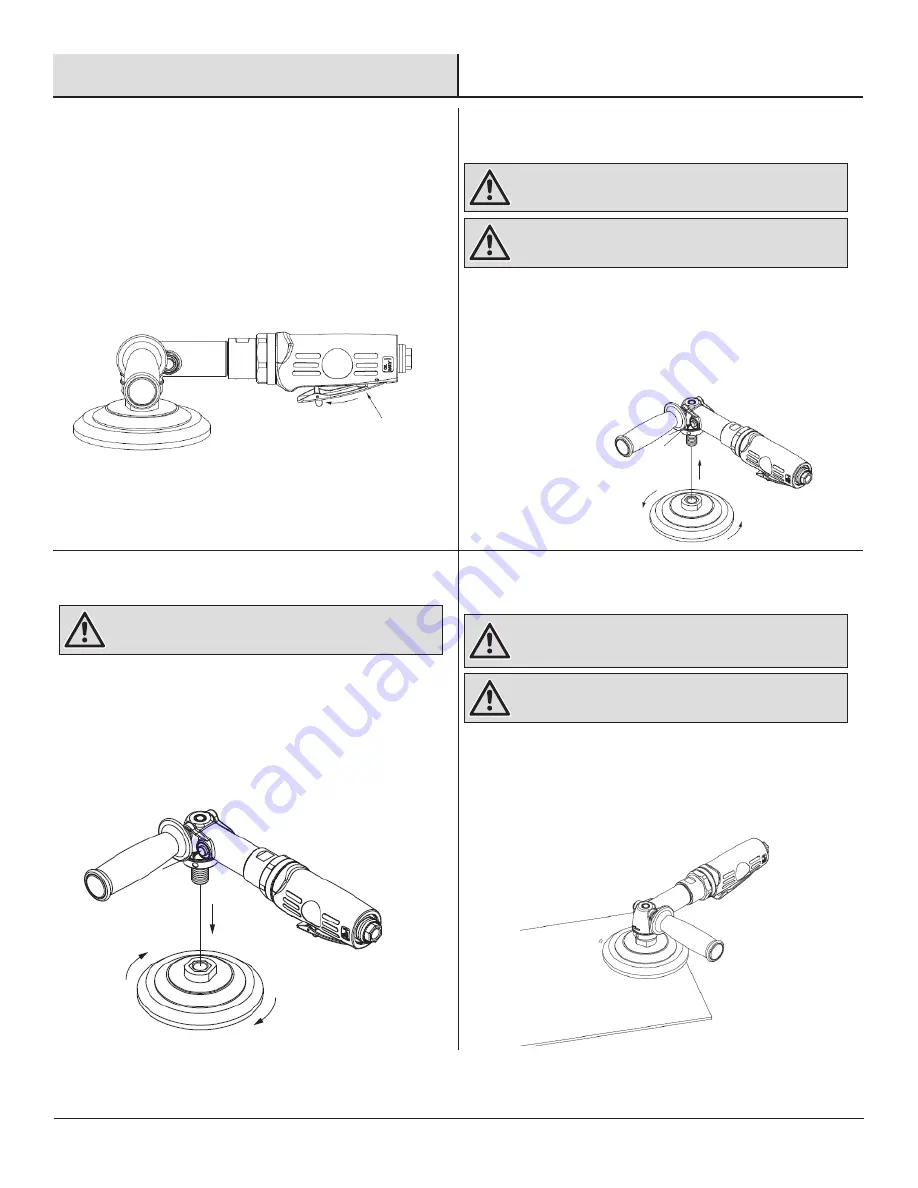

2

Installing the sanding pad

WARNING:

Disconnect the tool from the air source before

servicing or changing any accessories.

WARNING:

Always use the sanding discs with the rated

tool RPM.

□

Lock the drive spindle in place before attaching the sanding

pad. Rotate the spindle lock until the spindle lock engages

with the drive spindle. Hand tighten the sanding pad in a

clockwise direction.

3

Removing the sanding pad

WARNING:

Disconnect the tool from the air source before

servicing or changing any accessories.

□

Unlock the drive spindle and rotate to remove the sanding pad.

4

Sanding surfaces

WARNING:

You must wear ANSI approved eye protection

during the operation; failure to follow this may result in

serious injury or damage to the operator.

WARNING:

Hearing protection is strongly recommended. A

protective respirator is recommended.

□

Connect the sander to the air supply.

□

This tool features a safety lock-off mechanism.

□

Operate the tool by disengaging the safety lock-off

mechanism and depressing the throttle lever to run the

tool for sanding.

Spindle Lock

Spindle Lock