UT9930

FPMC

4

Recoilless Air Saw

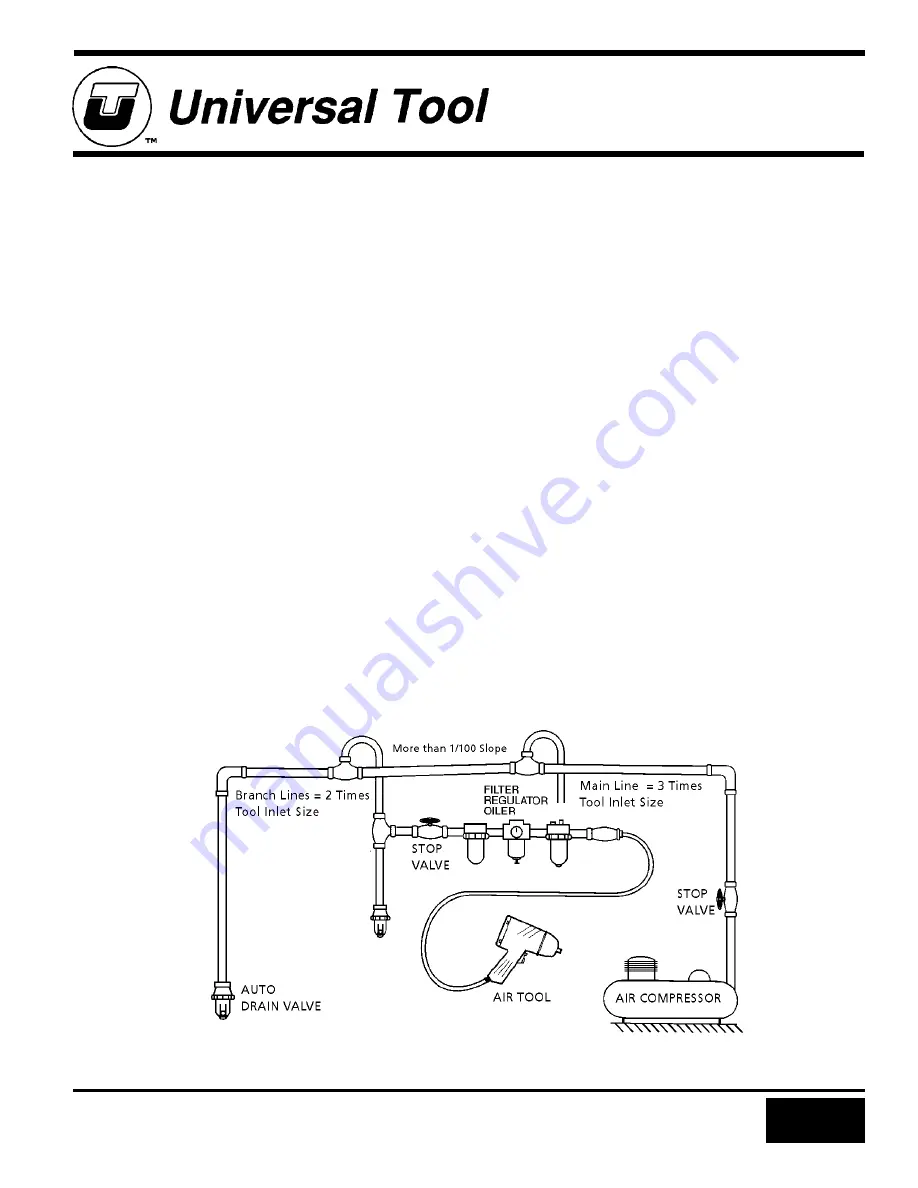

Recommended Air Line Set-Up

Trouble Shooting

Tool failure, loss of power or erratic action may be caused by factors outside the tool. Make the following checks:

1.

Check air pressure. For rated performance, 90 PSIG air pressure is required AT THE TOOL with tool operating. A

drop in air pressure may be caused by lowered compressor output, excessive drain on the air line or use of hose or

connections of improper size (or in poor condition).

2.

Check for wet or dirty air in system. Wet air tends to wash lubricant away from tool and may rust and corrode the

components. Dirt and foreign matter in the air supply will impede action of the tool and cause damage to the internal

mechanisms. If dirt or water has entered the tool, flush with Marvel air tool oil or equivalent.

Limited Warranty

Universal Tool warrants its tools to be free from defects in material and workmanship for one year from the date of

purchase. This warranty does not apply to tools which have been abused, misused, modified or repaired by someone

other than Universal Tool or its authorized service centers. If a Universal Tool proves defective in material of workman-

ship within one year after purchase, return it to any authorized service center or to Universal Tool, freight prepaid. Please

enclose your name, address and adequate proof of purchase date with a brief description of the defect. Universal Tool

will, at its option, repair or replace defective tools, free of charge. Repairs or replacements are warranted as described

above for the remainder of the warranty period. Universal Tool's sole liability and your exclusive remedy under this

warranty is limited to repair or replacement of the defective tool. There are no other warranties expressed or implied and

Universal Tool shall not be liable for incidental, consequential or special damages, or any other damages, costs or

expense of repair or replacement as described above.

7/98