13

QUICK START

3 - Apply a test print on a scrap of material and inspect the

impression. Make further adjustments as necessary until

a clear mark is applied with each test print. As soon as

you are satisfied with the print quality, the unit is ready

for production printing.

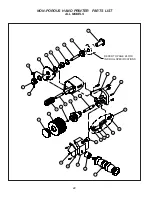

FIGURE 25

ADJUSTING THE INK ROLL ECCENTRIC

The Ink Roll is mounted on an axle which is position adjustable by rotating the Ink Roller Eccentric Adjusting

Knob. This feature is designed to provide compensation for slight variations in Ink Roll diameters. With the Ink

Roller Eccentric set at the “MIN” position, the Ink Roller will not make contact with the Anilox Roll. The position of

the Ink Roll needs to be adjusted so that it makes adequate contact with the Anilox Roll in order for it to transfer

ink properly. Too light a contact will result in the printing die not receiving enough ink to print and too heavy a

contact will apply excessive ink to the printing die.

1 - To find the proper position for the Ink Roll, rotate the

Eccentric Adjusting Knob from the “MIN” to the “1” posi-

tion.

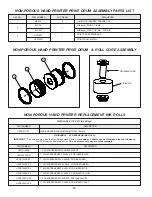

FIGURE 24

2 - Rotate the Print Drum and examine the face of the print-

ing dies for signs of ink. If no ink has been applied to the

die faces, rotate the Eccentric Knob a little more towards

the “MAX” position. Repeat this procedure, examining

the die faces each time, until the dies are fully coated

with ink. Typically, the ink roll will make proper contact

with the Anilox Roll when the Eccentric is near the “2”

position.

FIGURE 23

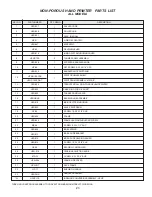

Summary of Contents for HPNP-100

Page 25: ...25 ...