17

MAINTENANCE

3 - Blot the surface of the die with a clean paper towel to dry

and reinstall the clean dies on the coder.

1 - Place the contaminated Printing Die on top of several

layers of paper towels to absorb the excess solvent.

Pour just enough solvent on the face of the printing die

to cover the die face.

Do not submerge or soak the dies in solvent as this may

cause swelling of the rubber compound.

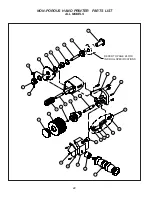

FIGURE 32

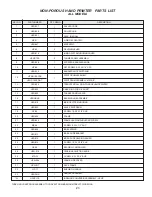

FIGURE 33

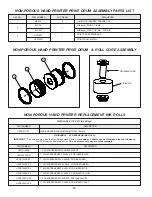

FIGURE 34

2 - Using the toothbrush, carefully scrub the face of the

die to remove the contamination and old ink. Add more

solvent as necessary and repeat the process until the

die is clean.

CLEANING THE PRINTING DIES

All inks which are formulated for printing on non-porous surfaces contain a resin binder which bonds the dye or

pigment in the ink to the surface of the material being printed. As the ink begins to dry, this binder becomes

“tacky” or “sticky”. While in this stage of the drying process, the tack on the dies will tend to pick up both airborne

dust and any dust or dirt on the surface of the material being printed. When this happens, the dies should be

cleaned or replaced. The easiest method of cleaning the dies requires the appropriate solvent for the ink being

used, a pair of rubber gloves, safety glasses, an apron to protect your clothing is recommended, a toothbrush,

some clean paper towels and a plastic bag to protect your workbench from staining. (Naturally, the toothbrush

will never be suitable for oral hygiene use after this process.)

After some period of use, the accumulation of contaminates on the dies will cause degradation of the print quality;

cleaning the printing dies, excluding excessive wear to the die face, will restore the print quality of the coder.

Summary of Contents for HPNP-100

Page 25: ...25 ...