8512

REPAIR INSTRUCTIONS

(including disassembly, replacement and reassembly)

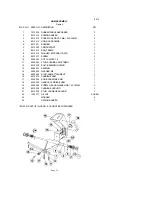

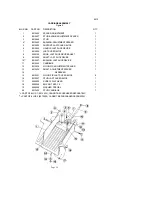

KNIFE

(Removal) (Figure 3)

1.

WARNING

Disconnect electrical power cord.

2. Remove carriage assembly (Fig. 6).

3. Remove knife guard knob (Fig. 3 [35]) and carefully remove knife guard.

4. Loosen sharpener lock pin (Fig. 7 [13]), lift and relock in up position.

5.

WARNING

Using caution to avoid the sharp knife edge, remove the four screws (Fie. 3 [ 15]).

6. Carefully remove knife and set aside with its flat side down flush on a bench so the edge is

not exposed.

7. Reinstall new knife in the reverse procedures outlined above.

8. Even though a new knife is very sharp, the sharpening procedure specified on pages 6 and 7

should be performed to true the new knife's bevel to the slicer.

WARNING:

Worn knife should be disposed of in a safe responsible way, showing concern for

others who may handle it. It recommended that the edge of the knife be wrapped

several times with heavy tape and that a caution (CAUTION, SHARP EDGE) be

written on both sides of the knife.

KMFE SEAL

(Figure 3)

1. Remove knife per above instructions.

2. Unscrew and remove tapered bushing (Fig. 3 [ 12]). Maintain shims that may have been used

in assembly.

3. Using a small screwdriver, carefully pry and remove the knife seal (Fig. 3 [13]) from knife

support (Fig.3 [8]).

4. Apply light film of mineral oil on outer diameter and lip of rubber seal.

KNIFE SUPPORT

Figure 3

1. KNIFE SUPPORT ASSEMBLY

A. Remove knife per above instructions.

B. Loosen lama (Fig. 3 [36]) by holding tapered bushing (Fig. 3 [12]) while turning lama

with allen wrench.

C. Elevate left side or lama side of machine 3-1/2" to prevent oil from spilling.

D. Remove oil.

Page 9