2850 Ravenswood Road, Fort Lauderdale, FL 33312 U.S.A.

Customer Service: 800.323.2111 • 954.584.2000 • Fax: 954.587.0109

info@uniweld.com • www.uniweld.com

55.4 87.7

107.9 309.5

T1 ˚F

T2

Lo

Hi

Psig

APO

HOLD MAX MIN

Psig

MENU

PAIR

O

Enter

Right

––––

Hold

Left

––––

Max Min

Down

––––

–

Up

––––

+

TM

MENU

PAIR

Right

––––

Hold

Left

––––

Max Min

O

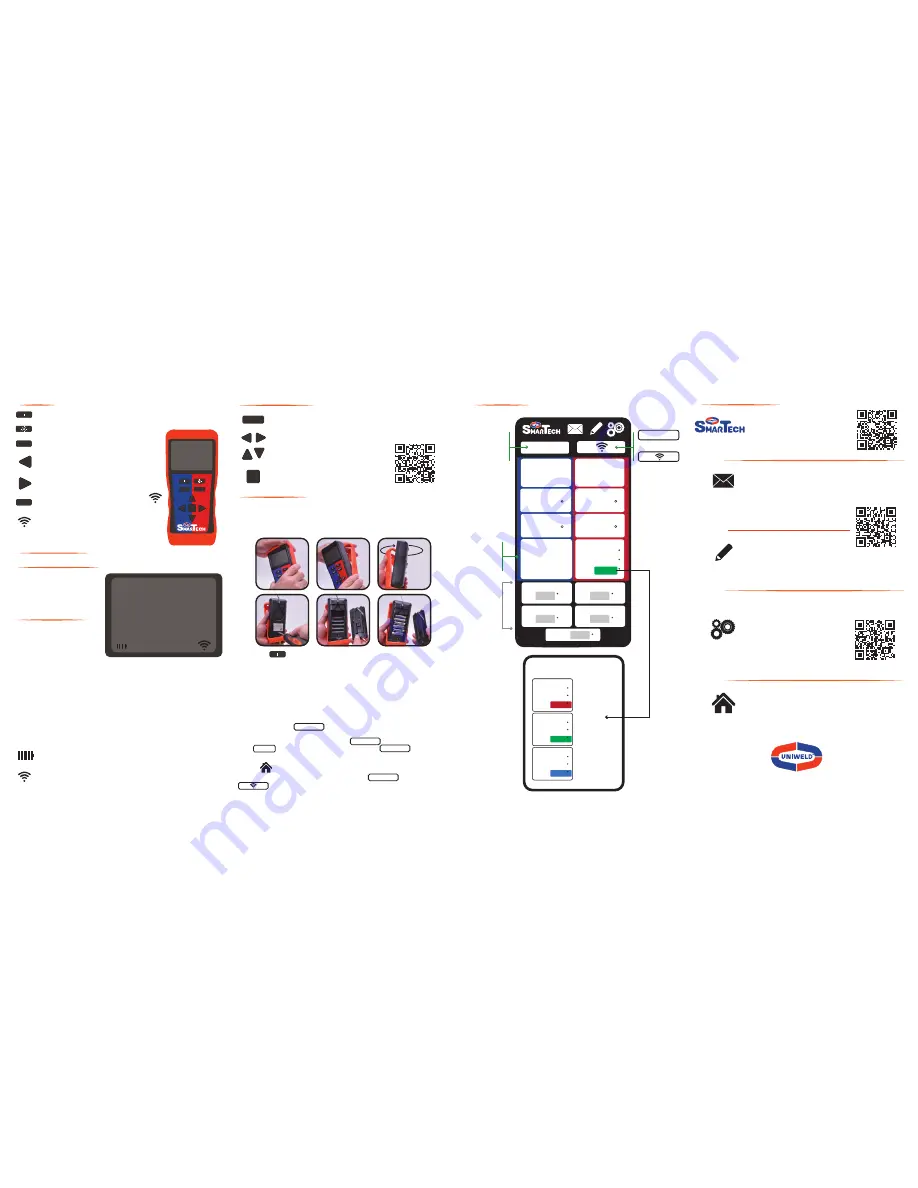

Power Button, Hold for 2 seconds to power On/OFF meter.

Backlight Button, On/OFF

Menu Button, push to enter menu functions

Left or Max/Min Button, Push once to activate

and repeat to cycle through options

Right or Hold Button, Push once to activate.

Push again to deactivate

Pair Button, On/Off Wireless BLE Module.

When powered on, the wireless

module will strobe when searching for smart

device. When connected with smart device,

symbol will indicate signal strength.

Display Features

Temperature Readings:

T1

Low Side Temperature

T2

High Side Temperature

ºC

Degree Celsius

ºF

Degree Fahrenheit

Pressure Readings:

Lo

Low Side Pressure

Hi

High Side Pressure

Psig

Pressure (pounds/in

2

)

Bar

Pressure (bar)

kPa

Pressure (kilo-Pascals)

Kg/cm

2

Pressure (kilograms/centimeter

2

)

inHg

Negative Pressure (inches of mercury)

cmHg

Negative Pressure (cm of mercury)

Hold

Value is held

Max

Show maximum value in record mode

Min

Show minimum value in record mode

APO

Auto Power Off enabled, Settings; 30 Min., 120 Min. or Manual

ON/OFF

Battery Life indicator

When powered on, the wireless module will strobe while searching

for smart device. When connected with smart device, symbol will

indicate wireless connection strength.

Controls

Down

––––

–

Up

––––

+

MENU

Right

––––

Hold

Left

––––

Max Min

O

ROTATE

RUBBER

BOOT

Enter

Getting Started

1. Install (6) AA batteries by removing the protective rubber boot. Start at the top

of the meter and rotate boot around meter to gain access to the rear battery

compartment. NOTE: Do not peel back and bend the protective rubber boot

as this may stretch and deform the material.

2. Hold the

Power Button

for 2 seconds to power on your new manifold.

3. Connect hoses and temperature clamps to manifold; use the Velcro cable straps

to organize the lead wires onto the blue and red hoses. Attach protective padded

case and secure to meter with velco straps.

4. Download the free Uniweld SmarTech Digital Manifold app on your compatible

smart device from the Google Play Store or the Apple App Store.

Open app and send email registration; once completed the app will open and

appear on your smart device.

You are now ready to CONNECT to the SmarTech Manifold.

5. Turn on the SmarTech Manifold and press CONNECT on the app.

Press SCAN and the USMAN device will appear. Press CONNECT (wait 5

seconds), your meter will beep once confirming connectivity.

6. Press to go back to the Home Screen and view system’s real-time pressures,

temperatures, Superheat and Subcooling readings. CONNECT will change to

indicating connectivity.

UNBOXING

Menu Navigation

Menu button accesses Auto Power, Pressure, and Temperature

preferences.

Right and Left buttons navigate menu options.

Up and Down buttons change the preference

in the menu.

Enter button selects the preference.

Press the SmarTech logo to visit the

website for tutorial videos, FAQ,

and Resources.

Export a SmarTech Verified Report and

email system performance data as a PDF

or CSV file that can be easily tracked and

saved. Images from the jobsite can be

attached to the email for a complete

back up report before and after the

work is completed.

Enter data for Company Information,

Project Details, and Project Notes

that will be saved and automatically

appear in the SmarTech Verified Report.

Project Details and Project Notes must

be edited for each job location.

Device Settings for Wireless

and Manual Input, Superheat and

Subcooling Input, Elevation, Email

Preferences, and Update Profile.

There are also instructions for

restoring the meter to Factory

Default, Temperature and Pressure

Calibration, and selecting Pressure

and Temperature preferences.

Pressing the HOME button will take you back to the

Home Screen.

Home Screen

Home Screen Icons

REPORT

SETTINGS

HOME

REPORT

CONNECT

CONNECTED

Select from

109 refrigerant

profiles and

create saved list

or

or

R-410A

35.0

VAPOR SATURATION

F

F

F

F

LIQUID SATURATION

98.0

107.9

LOW SIDE

PSIG HIGH SIDE

PSIG

309.5

TARGET

ACTUAL

10.0

10.3

LOW TEMP

55.4

HIGH TEMP

87.7

OUTDOOR DRY BULB

INDOOR WET BULB

RETURN AIR DRY BULB

SUPPLY AIR DRY BULB

DELTA T

F

F

F

F

F

DIFF.

00.3

F

F

F

SUBCOOLING (TXV)

SUPERHEAT (NON-TXV)

TM

SUPERHEAT (NON-TXV)

NON-TXV

PUSH HERE

NON-TXV

PUSH HERE

TXV

PUSH HERE

MANUAL

DATA

ENTRY

82.4

57.0

68.4

20.2

48.2

TARGET

System is

over charged

with refrigerant

and requires

removal of excess

refrigerant

ACTUAL

10.0

14.6

F

F

DIFF.

4.6

F

SUBCOOLING

(TXV)

RED ZONE

TARGET

System is

properly charged

for maximum

efficiency and

optimal performance

ACTUAL

10.0

10.3

F

F

DIFF.

0.3

F

SUBCOOLING

(TXV)

GREEN ZONE

TARGET

System is

under charged

and requires

additional

refrigerant

ACTUAL

10.0

4.2

F

F

DIFF.

5.8

F

SUBCOOLING

(TXV)

BLUE ZONE

SMART CHARGE ZONE™

Color coded differential for

accurate “In the Zone” system charge.

APP