Scales - Models 410 and 520

— Operation & Maintenance

3-17

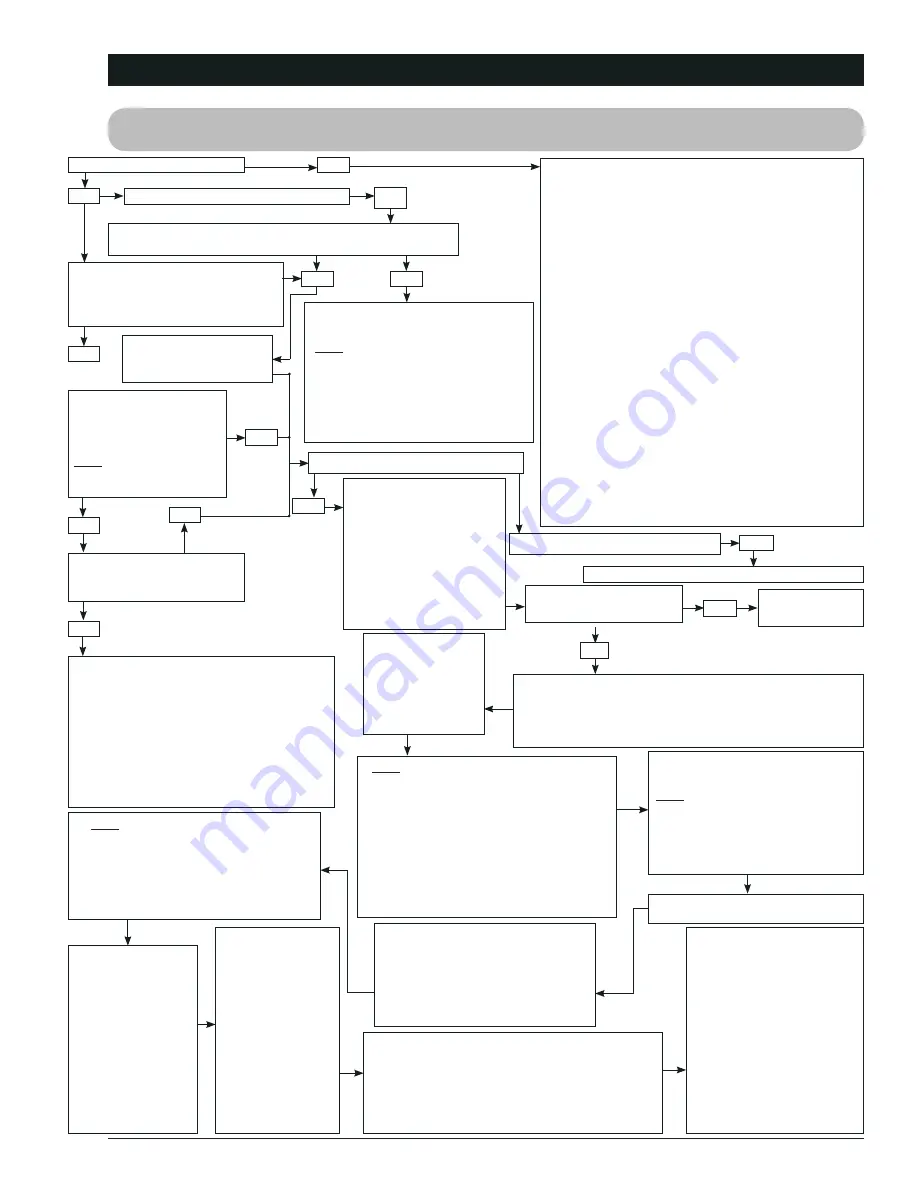

Does the indicator come on?

No

Yes

Is the reading on the indicator stable?

No

If your display is unstable, or flashes “Range” disconnect the

J-Block cord from the indicator. Is the display still unstable.

Stand on, or hang your weight over,

each load cell. Does the indicator

respond to your weight when you

stand, or hang, on the scale?

No

Check all J-Block and

load cell cables for cuts

or pinched/flat spots.

Your indicator is probably defective.

Try another indicator to verify.

NOTE: Be aware of electrical interfer-

ence that might affect your scale such

as: mobile phones, CB radios, radio

towers, electrical motors, etc. Also

make sure load cell cables are not

attached to hydraulic lines or reservoir

because of static electricity.

Does the scale weigh

you CORRECTLY with your

weight over any of load

cells?

NOTE: Are the readings all

positive? If not, the load

cell is upside down.

No

No

No

Remove the cover from the J-Block.

Does the scale weigh you ap-

proximately the same over all

three load cells?

Yes

Look for loose connections.

If you watch your indica-

tor display while moving

the wires around inside the

J-Block, and by pressing on

the J-Block printed circuit

board, you will see if there

is a loose connection of

bad solder joint.

Have you found a bad con-

nection or a loose wire?

Yes

Dry out your J-Block. (A hair dryer works great.)

Is there moisture inside the J-Block?

Yes

BAD INDICATOR: If you suspect a bad indicator, the

easiest way to check is to try another indicator. Even

if the indicator is a different model or is set-up for a

different scale, it at least should come on.

POOR CONNECTION: Poor connections can be tricky. If

in doubt, don’t just tighten the connection, take them

apart and clean them first. Any connection with rust or

paint should be sanded or wired brushed.

BAD BATTERY: If you suspect the battery, try replacing

it with another one. Don’t be fooled if using a voltme-

ter to test you battery. A weak battery may test good

if checked when there is no load on the battery.

BAD POWER CORD: Make sure the power cord’s red wire

is connected to the plus (+) positive side of the battery,

and the black (-) negative wire is connected to the

negative side of the battery. If using a multi-meter to

check for voltage measure between pin 1 (POS) and pin

2 (NEG). The meter should read between 10.5 and 14.6

volts DC. If using a tractor power cord, the black wire

on the tractor power cord is positive and the white wire

is negative. Voltage from scale indicator should read

between 7.8 and 8 volts.

Fix or replace the

J-Block.

ZERO balance the in-

dicator. (First press

the [FIELD] net/gross

key then the [ZERO]

key.) The indicator

should display “0”.

Disconnect all the load cell wires from the terminal blocks

inside the J-Block. (You can leave the indicator on while

connecting or disconnecting the load cell wires, you will not

damage the load cells or indicator if wires are shorted durn-

ing this step.)

No

Your indicator is probably not set-up and cali-

brated correctly. Check the decal on the bot-

tom of the indicator. The decal shows what

type of load cells the indicator was calibrated

to. By pressing the [ON] key while the indi-

cator is already on, you will get the indicator’s

“SET-UP” and “CAL” numbers. Write these

down and see if they compare to the set-up

and calibration numbers on the indicator.

Contact your dealer for further information.

NOTE: You are going to hook-up the load

cells to the J-Block one at a time (meaning

only one load cell connected at a time). The

purpose of this is to get a reading for each

load cell. Also while performing this test,

you should watch for any other symptoms

such as erratic/unstable display, indicator

flashing “RANGE”, or a negative reading, etc.

If the indicator reading should ever appear

abnormal with any load cell connected, that

load cell is probably bad.

Connect one load cell back into on

of the terminals in the J-Block.

NOTE: The reading you get for each

load cell is dependent on the size

and type of load cell and how much

weight is over each cell. In general,

the number should be a positive and

be stable.

Write down the indicator reading with

the load cell connected.

NOTE: If the scale responded to your

weight, that’s verification that the J-Block is

OK. If the scale did not respond to your

weight, either that load cell is bad or the

J-Block is bad. Try another load cell. If

the scale still shows no response to your

weight, the J-Block is probaly bad.

Stand or hang your weight over the

connected load cell. Write down how

much the weight increased with your

weight over the load cell. (Don’t be

alarmed by the reading, a scale with

only one load cell connected will

weigh heavy.)

Disconnect the

first load cell and

reconnect a second

one. Write down the

indicator reading for

that load cell. Stand

or hang your weight

over the connected

load cell. Write down

how much the weight

increased with your

weight over the load

cell.

Disconnect the

second load cell and

reconnect the third

load cell. Write

down the indication

reading for that load

cell also. Stand or

hang you weight over

the connected load

cell. Write down

how much the weight

increased with your

weight over the load

cell.

Do not expect the load cells to give you the same

reading. It is common for each load cell to have

a reading that is hundreds, maybe even thousands,

different than the others. Especially when one

load cell is carrying more weight than the others.

(Example: the two axial load cells will be carrying

more weight than the hitch bar.)

A bad load cell will have a

reading that is either unstable,

or makes the indication flash

“±RANGE”, or is more than

three times greater, or less

than the average of the oth-

ers. Additionally the readings

of your weight over each load

cell should be similar. (Prob-

ably 2-3 times your actual

weight, but similar to each

other.) Any difference could be

an indication of a bad load

cell or structural problem.

Yes

Yes

Yes

Scale Troubleshooting