U P O N O R E C O F L E X S U P R A P L U S C A B L E S E T S 1

•

M O U N T I N G I N S T R U C T I O N

1 6

1 6

Uponor Ecoflex Supra PLUS control unit

Product description

The Uponor Ecoflex Supra PLUS control unit is

an electronic regulator developed to control the

Uponor Supra Plus water pipe, which is fitted

with a self-adjusting heat cable. The control unit

has two different functions. You can select either

thermostat control equipped with a temperature

sensor, or an operation time clock function based

on a fixed time period.

Installation instructions

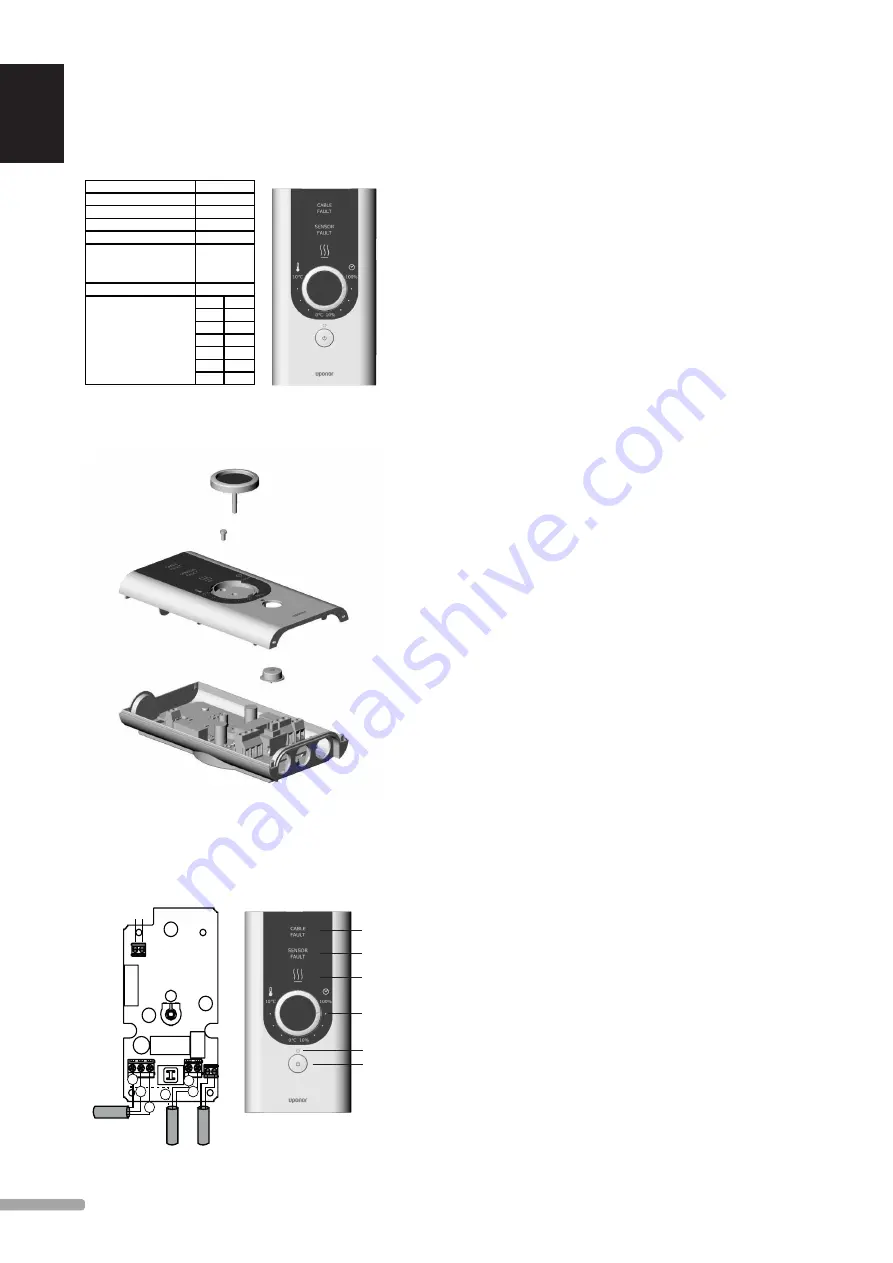

(Figure 2)

Fix the base of the housing to the wall with

screws (hole interval 60 mm, maximum screw

head diameter 6.5 mm). The tightness class of the

surface installation housing is IP23. The housing

can also be mounted on top of an instrument

box, in which case the tightness class is IP20. The

fixing holes are dimensioned according to the

most generally used instrument boxes. On the

back cover of the housing, for installation on top

of an instrument box, an area with reduced thick-

ness has been provided, which can be pierced for

the lead-through of cables. Fix the cover of the

housing to the base part with M2.5 screws. If the

lead-through seals to be used are any other than

those supplied in the package, then they must

be approved for the cable thickness to be used

and for tightness class IP23. Install the sensor in

the Uponor Ecoflex Supra PLUS pipe element, in

the conduit provided for it. The sensor is supplied

ready-installed inside the insulating sleeve. Lead

the insulating sleeve through the lead-through

seal and into the conduit of the pipe element,

so that it functions as a protector for the sensor

cable. If possible, the sensor should be installed

at the point that is the most susceptible to free-

zing. If the sensor cannot be put at the coldest

point, then this must be taken into account in the

control unit settings or an operation time clock

must be used.

Connection

(Figures 2 and 3)

Remove the adjusting wheel, detach the fixing

screw and remove the cover part of the control

unit (Figure 2). Connect the 230 V AC supply

cable (Figure 3a), the sensor cable (Figure 3b),

the heat cable of the Supra (Figure 3c) and the

protective earth, to the incoming supply cable

and the protective flex of the heat cable. The

thickness of the connecting wires is determined

according to the size of the main fuse. 10A -> 3

x 1.5 mm

2

and 16A -> 3 x 2.5 mm

2

. The instal-

lations should be carried out in accordance with

the fixed installation method. The control unit

also has a potential-free switch (230 VAC or SELV

voltage, max load 5A) for remote control, which is

activated in a fault situation. If necessary, punch

a hole in the top part of the device for the remote

monitoring cable, which must be laid according to

the requirements of the control voltage.

Start-up and use

(Figure 4)

Turn on the Uponor Ecoflex Supra PLUS control

unit using the switch (f). When the control unit is

on, the green indicator light (e) above the switch

will go on. Select the function alternative to

be used. The selection is made by setting the

adjusting wheel of the control unit to the

desired adjustment range. The left adjust-

ment range (pos. 6-10) is for the thermostat

function, and the right one (pos. 2-6) is for

the operation time clock. The adjustment

ranges are limited by a mechanical barrier. If

you wish to change the mode of operation,

pull the adjusting wheel outwards from

the control unit and turn the wheel to the

desired adjustment range (the mechanical

barrier limiting the adjustment ranges is at

the 6 o’clock position).

The adjustment range for the thermostat

function of the Uponor Supra Plus control

unit is 0…10°C. If the adjusting wheel is set

to the 0 point of the adjustment range, then

the control unit will endeavour to keep the

temperature of the flow pipe at +0°C. The

temperature adjustment must nevertheless

be made according to the case, depending

on the location of the sensor and the envi-

ronment of use.

The adjustment range of the operation time

clock corresponds to a switching cycle of

30 minutes. In the maximum position, at

100 %, the heat cable is on throughout the

whole cycle. In the minimum position, at 10

%, the heat cable is on for 3 min. and off for

27 min. The cycle period should be selected

according to the case, depending on the

prevailing conditions. When the operation

time clock is being used for the thawing of a

frozen pipe, set the selector at 100 %. When

the heating load is in the switched-on state,

the red indicator light (c) above the adjusting

wheel will be on, showing that the cable is

being heated.

The control unit’s fault diagnostics system

will detect any breaks or short circuits in

the sensor cable and whether the heating

cable is connected or not. The top LED (a)

indicates that there is no load in the cable,

and the bottom LED (b) indicates that the

sensor is faulty (this check is only made in

the thermostat mode). If a fault occurs in the

sensor, the thermostat operation changes

automatically to the operation time clock. In

this case, the device operates at a fixed pulse

ratio of 50 %. In this fault situation, it is not

possible to adjust the operation time clock.

When the regulator is operating normally, a

faint clicking noise is heard when the heating

load goes on and off.

a) Supply

cable

230 VAC

b) Sensor

c) Heat

cable

Remote control

Pe

N

L

L

N

Pe

Figure 2

Figure 3

Figure 4

Operating voltage

230 VAC

Rated power

1500 W

Operating temperature range -20…+45C

Housing class

IP23

Indication by indicator light effective part

Adjustment range

- with thermostat

- with operation

0…10°C

10%…100%

Length of sensor cable

5 m

values of sensor

T°C R kΩ

0

29

5

23

10

18

15

15

20

12

25

10

a

b

c

d

e

f

SE

PT

NO

NL

IT

FR

FI

ES

DK

DE

UK