Page 12

TL50 Service & Parts

Transportation

B

A T T E R Y

M

A I N T E N A N C E

W A R N I N G

!

!

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with Ui batteries or manufacturer approved replacements weighing 26,3 kg

(58 lbs.) each.

• Check the battery fluid level daily, especially if the work platform is being used in a warm, dry climate.

• If electrolyte level is lower than 10 mm (

3

/

8

in.) above the plates add distilled water only. DO NOT use

tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

ATTERY

C

HARGING

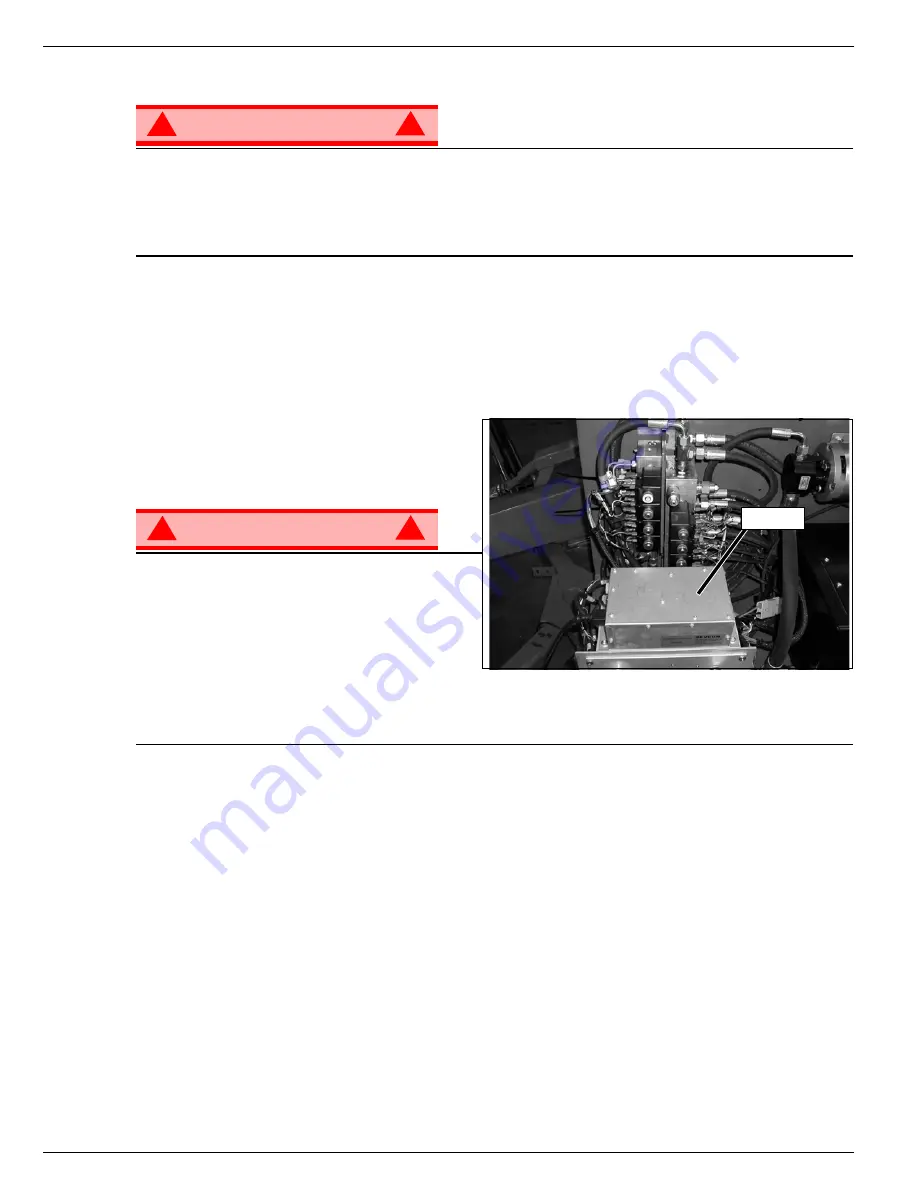

Figure 5:

Battery Charger

Charge the batteries at the end of each work

shift or sooner if the batteries have been dis-

charged.

W A R N I N G

!

!

Charge the batteries in a well ventilated area.

Do not charge the batteries when the work

platform is near a source of sparks or flames.

Permanent damage to the batteries will result if

the batteries are not immediately recharged

after discharging.

Never leave the battery charger operating for more than two days.

Never disconnect the cables from the batteries when the charger is operating.

Keep the charger dry.

1. Check the battery fluid level. If the battery fluid level is lower than 10 mm (

3

/

8

in.) above the plates add

distilled water only.

2. Connect an appropriate extension cord to charger outlet plug in Left Module Door. Plug the extension

cord into a properly grounded outlet of proper voltage and frequency.

3. The charger turns on automatically after a short delay. The LED charge indicator will illuminate. After

completion of the charge cycle the LED will blink, indicating that the charger is in a continuing mainte-

nance mode. DO NOT leave the charger plugged in for more than 48 hours, as permanent damage to

the batteries may occur.

NOTE:

The battery charger circuit must be used with a GFI (Ground Fault Interrupt) outlet.

NOTE:

DO NOT operate the machine while the charger is plugged in.

Charger

Summary of Contents for 503502-000

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL50...

Page 21: ...Page 16 TL50 Service Parts Specifications Notes...

Page 51: ...Page 3 30 Maintenance 3 19 Torque Specifications TL50 Service Parts NOTES...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL50 Service Parts...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL50 Service Parts...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL50 Service Parts...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL50 Service Parts...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL50 Service Parts Notes...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL50 Service Parts 1 1 2 3 4 5 6 7...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL50 Service Parts 44 45...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly Standard TL50 Service Parts...

Page 74: ...Page 6 11 Illustrated Parts Breakdown Platform Assembly Rotator TL50 Service Parts...

Page 88: ...Page 6 25 Illustrated Parts Breakdown Hydraulic Tank Assembly TL50 Service Parts...

Page 90: ...Page 6 27 Illustrated Parts Breakdown Electrical Assembly TL50 Service Parts...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Hydraulic Assembly TL50 Service Parts...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 96: ...Technician s Print TL50 W ork Platform Electrical Schematic...

Page 97: ...Technician s Print TL50 W ork Platform Harness Schematic...

Page 98: ......