Page 3-4

Maintenance

3.4 - Battery Maintenance

TL50 Service & Parts

3.4 B

ATTERY

M

AINTENANCE

Electrical energy for the motor is supplied by four 6 volt batteries wired in series for 24 volts DC.

Proper care and maintenance of the batteries and motor will ensure maximum performance from

the work platform.

NOTE:

If system voltage drops below 17 volts (on a 24 volt system), the charger will not recharge the

batteries. If this extreme voltage drop occurs, disconnect and recharge each battery separately, using a

6 volt charger to bring the voltage in each up to at least 4 1/2 volts.

B

ATTERY

I

NSPECTION

AND

C

LEANING

Check the battery fluid level daily, especially if the work platform is being used in a warm, dry cli-

mate. If required, add distilled water ONLY. Use of tap water will shorten battery life.

The battery should be inspected regularly for signs of cracks in the case, electrolyte leakage,

and corrosion of the terminals. Inspect cables for worn spots or breaks in the insulation and for

broken cable terminals.

Clean the battery when it shows signs of corrosion at the terminals or when electrolyte has over-

flowed during charging. Use a baking soda solution to clean the batteries, taking care not to get

the solution inside the cells. Rinse thoroughly with clean water. Clean the battery and cable con-

tact surfaces to a bright metal finish whenever a cable is removed.

B

ATTERY

C

HARGING

Figure 3-1: Battery Charger

Charge the batteries at the end of each

work shift, or sooner if the batteries

have been discharged.

When night temperatures fall below

18°C (65°F), batteries charged in

unheated areas should be placed on

charge as soon as possible after use.

Under such conditions, a 4 hour

equalize charge once a week in the

early afternoon will improve the state

of charge and battery life.

W A R N I N G

!

!

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material

away from battery.

Always wear safety glasses when working with batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with

clean water.

C A U T I O N

!

!

If battery water level is not maintained, batteries will not fully charge,

creating a low discharge rate which will damage the motor/pump unit and

void the warranty.

Summary of Contents for 503502-000

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL50...

Page 21: ...Page 16 TL50 Service Parts Specifications Notes...

Page 51: ...Page 3 30 Maintenance 3 19 Torque Specifications TL50 Service Parts NOTES...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL50 Service Parts...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL50 Service Parts...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL50 Service Parts...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL50 Service Parts...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL50 Service Parts Notes...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL50 Service Parts 1 1 2 3 4 5 6 7...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL50 Service Parts 44 45...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly Standard TL50 Service Parts...

Page 74: ...Page 6 11 Illustrated Parts Breakdown Platform Assembly Rotator TL50 Service Parts...

Page 88: ...Page 6 25 Illustrated Parts Breakdown Hydraulic Tank Assembly TL50 Service Parts...

Page 90: ...Page 6 27 Illustrated Parts Breakdown Electrical Assembly TL50 Service Parts...

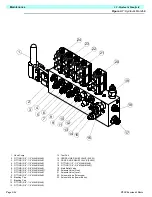

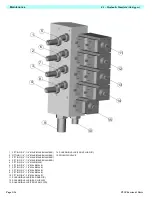

Page 92: ...Page 6 29 Illustrated Parts Breakdown Hydraulic Assembly TL50 Service Parts...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 96: ...Technician s Print TL50 W ork Platform Electrical Schematic...

Page 97: ...Technician s Print TL50 W ork Platform Harness Schematic...

Page 98: ......