Page 3-12

Maintenance

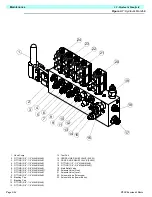

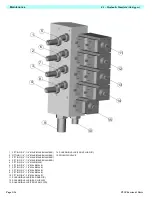

3.8 - Setting Hydraulic Pressures

TL50 Service & Parts

S

LEW

C

ROSS

-L

INE

R

ELIEF

VALVES

1. Operate the hydraulic system for 10-15 minutes to warm the oil.

2. Remove the cover from the 1st post.

3. Insert pressure gauge into high pressure gauge port marked ‘PT’ on top of front face of main

manifold block.

4. Loosen locknuts on both cross-line relief valves and turn adjusting screws counter clockwise

two full turns.

5. Operate slew function from lower controls and rotate elevating assembly through approx.

180o until the slew stop prevents further rotation.

6. Slowly turn the cross-line relief valve adjusting screw clockwise until the pressure gauge

reads 50 Bar pressure.

7. Now operate the slew function in the opposite direction through approx. 360o until the slew

stop prevents further rotation.

8. Slowly turn the remaining cross-line relief valve adjusting screw clockwise until the pressure

gauge reads 50 Bar pressure.

9. Tighten the locknuts on both cross-line reief valves while holding the adjusting screws in posi-

tion.

Summary of Contents for 503502-000

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL50...

Page 21: ...Page 16 TL50 Service Parts Specifications Notes...

Page 51: ...Page 3 30 Maintenance 3 19 Torque Specifications TL50 Service Parts NOTES...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL50 Service Parts...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL50 Service Parts...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL50 Service Parts...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL50 Service Parts...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL50 Service Parts Notes...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL50 Service Parts 1 1 2 3 4 5 6 7...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL50 Service Parts 44 45...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly Standard TL50 Service Parts...

Page 74: ...Page 6 11 Illustrated Parts Breakdown Platform Assembly Rotator TL50 Service Parts...

Page 88: ...Page 6 25 Illustrated Parts Breakdown Hydraulic Tank Assembly TL50 Service Parts...

Page 90: ...Page 6 27 Illustrated Parts Breakdown Electrical Assembly TL50 Service Parts...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Hydraulic Assembly TL50 Service Parts...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 96: ...Technician s Print TL50 W ork Platform Electrical Schematic...

Page 97: ...Technician s Print TL50 W ork Platform Harness Schematic...

Page 98: ......