Page 3-27

Maintenance

3.19 - Torque Specifications

TL50 Service & Parts

3.19 T

ORQUE

S

PECIFICATIONS

H

YDRAULIC

C

OMPONENTS

NOTE:

Always lubricate threads with clean hydraulic oil prior to installation

Use the following values to torque hydraulic components used on UpRight Work Platforms.

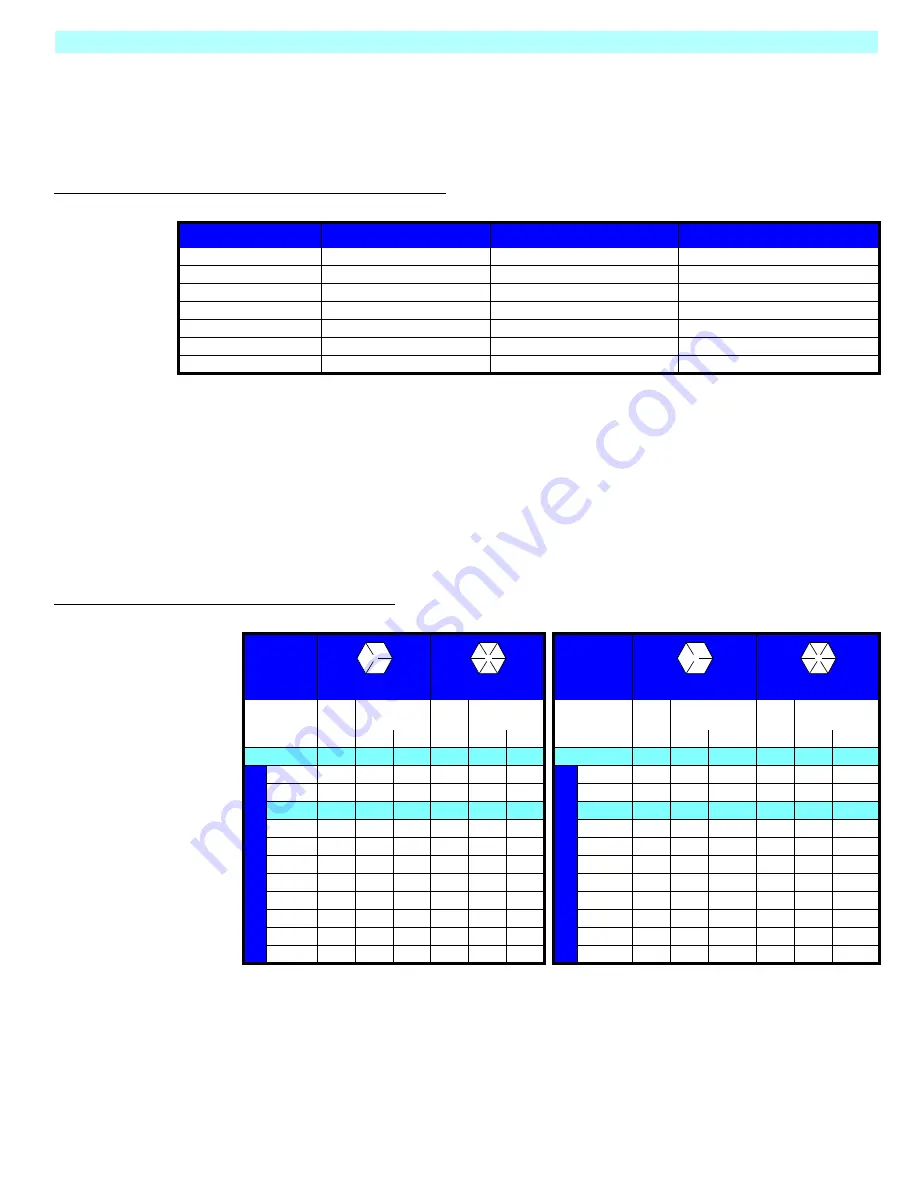

Table 3-1: Torque Specifications for Hydraulic Components

F

ASTENERS

This standard applies to the preloading of fasteners measured by installation torque.

NOTE:

For other preloading methods or fasteners, consult UpRight Engineering Department.

This general standard applies to all SAE and Metric fasteners, unless otherwise specified.

T

HREAD

C

ONDITION

• For lubed or zinc plated fasteners, use K = .15

• For dry unplated fasteners, use K = .20

T

ORQUE

T

ABLES

Table 3-2: Torque Specifications for SAE Fasteners

Type: SAE Part Series

Cartridge Poppet

Fittings

Hoses

Ft/Lbs

Nm

Ft/Lbs

Nm

Ft/Lbs

Nm

#4

N/A

N/A

N/A

N/A

135-145

15-16

#6

N/A

N/A

10-20

14-27

215-245

24-28

#8

25-30

34-41

25-30

34-41

430-470

49-53

#10

35-40

47-54

35-40

47-54

680-750

77-85

#12

85-90

115-122

85-90

115-122

950-1050

107-119

#16

130-140

176-190

130-140

176-190

1300-1368

147-155

SAE J429 Grade 5

SAE J429 Grade 8

SAE J429 Grade 5

SAE J429 Grade 8

Nominal

Thread Size

Clamp

Load

Tightening

Torque

Clamp

Load

Tightening

Torque

Nominal

Thread Size

Clamp

Load

Tightening

Torque

Clamp

Load

Tightening

Torque

K=.15 K=.20

K=.15 K=.20

K=.15

K=.20

K=.15

K=.20

lbs.

in-lbs. in-lbs.

lbs.

in-lbs. in-lbs.

lbs.

in-lbs.

in-lbs.

lbs.

in-lbs.

in-lbs.

U

n

if

ie

d Co

ar

se

Th

re

ad

Se

ri

e

s

1/4 -20

2,000

75

100

2850

107

143

Un

ifie

d

Fin

e

Th

re

ad

Se

rie

s

1/4 -28

2,300

85

115

3250

120

163

5/16 - 18 3,350

157

210

4700

220

305

5/16-24

3,700

173

230

5200

245

325

lbs.

ft-lbs. ft-lbs.

lbs.

ft-lbs. ft-lbs.

lbs.

ft-lbs.

ft-lbs.

lbs.

ft-lbs.

ft-lbs.

3/8-16

4,950

23

31

6950

32.5

44

3/8-24

5,600

26

35

7900

37

50

7/16-14

6,800

37

50

9600

53

70

7/16-20

7,550

42

55

10700

59

78

1/2-13

9,050

57

75

12800

80

107

1/2-20

10,200

64

85

14400

90

120

9/16-12 11,600

82

109

16400

115

154

9/16-18

13,000

92

122

18300

129

172

5/8-11

14,500

113

151

20300

159

211

5/8-18

16,300

128

170

23000

180

240

3/4-10

21,300

200

266

30100

282

376

3/4-16

23,800

223

298

33600

315

420

7/8-9

29,435

321

430

41550

454

606

7/8-14

32,480

355

473

45855

500

668

1-8

38,600

483

640

54540

680

900

1-12

42,270

528

704

59670

745

995

Summary of Contents for 503502-000

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL50...

Page 21: ...Page 16 TL50 Service Parts Specifications Notes...

Page 51: ...Page 3 30 Maintenance 3 19 Torque Specifications TL50 Service Parts NOTES...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL50 Service Parts...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL50 Service Parts...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL50 Service Parts...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL50 Service Parts...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL50 Service Parts Notes...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL50 Service Parts 1 1 2 3 4 5 6 7...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL50 Service Parts 44 45...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly Standard TL50 Service Parts...

Page 74: ...Page 6 11 Illustrated Parts Breakdown Platform Assembly Rotator TL50 Service Parts...

Page 88: ...Page 6 25 Illustrated Parts Breakdown Hydraulic Tank Assembly TL50 Service Parts...

Page 90: ...Page 6 27 Illustrated Parts Breakdown Electrical Assembly TL50 Service Parts...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Hydraulic Assembly TL50 Service Parts...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 96: ...Technician s Print TL50 W ork Platform Electrical Schematic...

Page 97: ...Technician s Print TL50 W ork Platform Harness Schematic...

Page 98: ......