Page 4-3

Troubleshooting

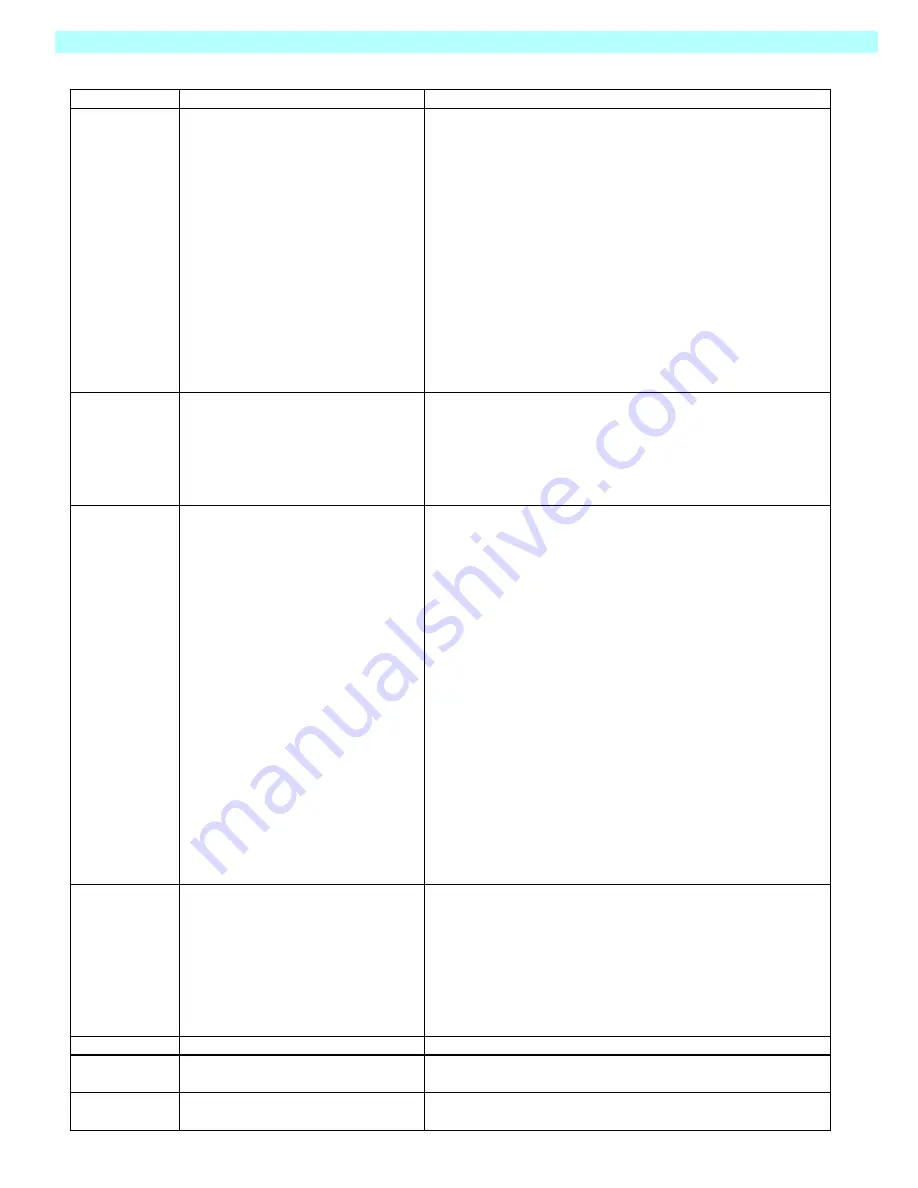

4.3 - Troubleshooting Guide

TL50 Service & Parts

TROUBLE

PROBABLE CAUSE

REMEDY

1. Blown electric motor fuse

Check 160 amp electric motor fuse. Replace if blown.

2. Faulty battery

Check the voltage output of the battery charger. If less than 24 VDC,

charger.

3. Faulty battery(ies).

After completely charging batteries, test each battery. Replace as

4. Loose or broken

Check continuity of all battery and motor leads. Replace if necessary.

battery lead.

5. Emergency Stop

With emergency stop switch in the ON position, check continuity

switch(es) failed open.

6. Blown control fuse

Check 7A circuit control fuse. Replace if blown.

1. Oil level in hydraulic

Check hydraulic fluid level, top off as required.

reservoir is low.

2. Faulty hydraulic

Check pressure and delivery of the hydraulic pump. Replace if

pump.

1. Emergency

Close emergency

Lowering valve

down valve.

open.

2. Platform

Observe maximum load rating. (see Operation section of this manual)

overloaded.

3. Faulty controller at

Check functionality of controller. Replace if faulty.

upper controls.

4. Blown control fuse

Check 7A circuit contrrol fuse. Replace if blown.

5. Battery level low.

Check Battery Voltage. Charge if necessary.

Check for fault code 68

6. Outrigger limit

Ensure all four outriggers are deployed and the

switches not activated

limit switch contacts are closed.

Replace switch.

1. Emergency

Ensure that emergency lowering valve is completely closed. Replace

lowering valve

open.

2. Leaking piston

Check for leakage at cylinder return line, replace seals if necessary.

seals in lift

cylinders

Outrigger

Boom rest limit switch is not activated or Ensure booms are stowed. Check that Normally Open contacts of limit

Check that Normally Closed contacts of limit switch are closed when

Adjust switch lever arm or Replace switch.

Tele cylinder will

retract or extend.

All functions

inoperable,

electric motor

does not start.

All functions

inoperable.

Electric motor

starts when

control is

actuated.

Platform will not

elevate or

elevates slowly.

Close Shutoff ball valve.

Booms drift down

after being

elevated

Machine will not

slew when booms

Faulty slew cut-out limit switch

Shutoff ball valve is open.

4.3 T

ROUBLESHOOTING

G

UIDE

Summary of Contents for 503502-000

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL50...

Page 21: ...Page 16 TL50 Service Parts Specifications Notes...

Page 51: ...Page 3 30 Maintenance 3 19 Torque Specifications TL50 Service Parts NOTES...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL50 Service Parts...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL50 Service Parts...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL50 Service Parts...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL50 Service Parts...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL50 Service Parts Notes...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL50 Service Parts 1 1 2 3 4 5 6 7...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL50 Service Parts 44 45...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly Standard TL50 Service Parts...

Page 74: ...Page 6 11 Illustrated Parts Breakdown Platform Assembly Rotator TL50 Service Parts...

Page 88: ...Page 6 25 Illustrated Parts Breakdown Hydraulic Tank Assembly TL50 Service Parts...

Page 90: ...Page 6 27 Illustrated Parts Breakdown Electrical Assembly TL50 Service Parts...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Hydraulic Assembly TL50 Service Parts...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 96: ...Technician s Print TL50 W ork Platform Electrical Schematic...

Page 97: ...Technician s Print TL50 W ork Platform Harness Schematic...

Page 98: ......