Summary of Contents for AB38

Page 2: ...ii AB38 Work Platform NOTES...

Page 4: ...ii AB38 Work Platform NOTES...

Page 6: ...iv AB38 Work Platform NOTES Foreword...

Page 10: ...Contents Section IV AB38 Work Platform i NOTES...

Page 14: ...Introduction Specifications Section 1 4 AB38 Work Platform NOTES 1 3...

Page 17: ...Machine Preparation Section 2 3 AB38 Work Platform NOTES 2 7...

Page 18: ...Machine Preparation Section 2 4 AB38 Work Platform 2 7 NOTES...

Page 29: ...Operation Section 3 11 AB38 Work Platform NOTES 3 5...

Page 30: ...Operation Section 3 12 AB38 Work Platform NOTES 3 5...

Page 59: ...Maintenance Section 4 29 AB38 Work Platform NOTES 4 21...

Page 60: ...Maintenance Section 4 30 AB38 Work Platform NOTES 4 21...

Page 66: ...Troubleshooting Section 5 6 AB38 Work Platform 5 7 NOTES...

Page 68: ...Schematics Section 6 2 AB38 Work Platform NOTES 6 0...

Page 72: ...Schematics Section 6 6 AB38 Work Platform 6 1 NOTES...

Page 73: ...Electrical Schematic Schematics 6 7 AB38 Work Platform Section 6 1...

Page 74: ...Electrical Schematic Schematics 6 8 AB38 Work Platform Section 6 1 TOP VIEW...

Page 76: ...Schematics Section 6 10 AB38 Work Platform NOTES 6 2...

Page 78: ...Section 6 2 6 12 AB38 Work Platform Schematics NOTES...

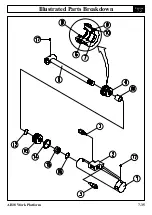

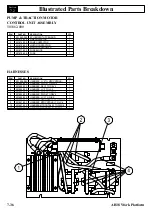

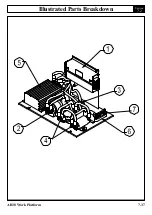

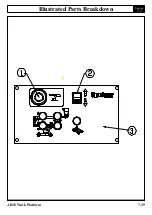

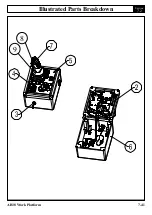

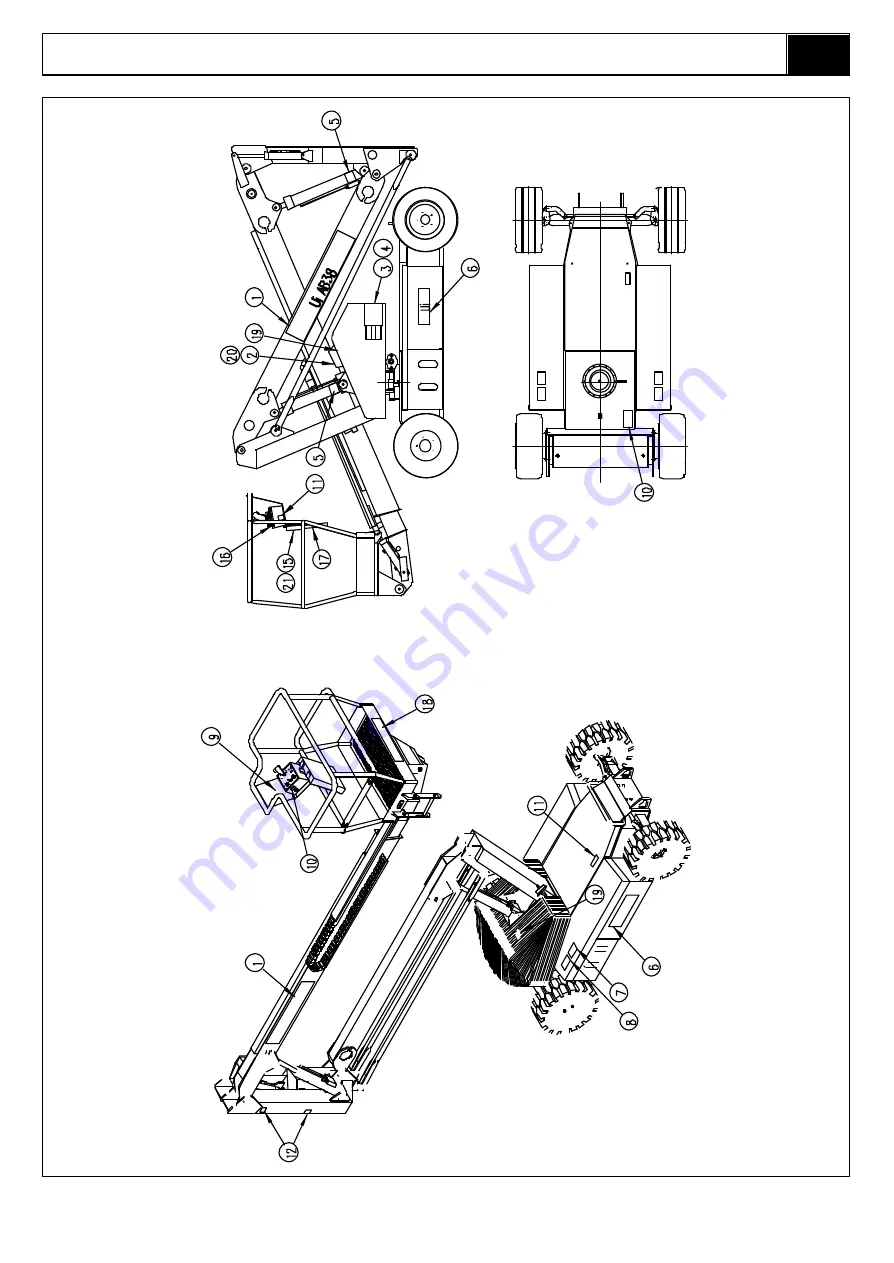

Page 81: ...Illustrated Parts Breakdown Section 7 3 AB38 Work Platform 7 2...

Page 83: ...Illustrated Parts Breakdown Section 7 5 AB38 Work Platform 7 2...

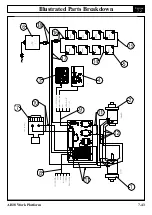

Page 85: ...Illustrated Parts Breakdown Section 7 7 AB38 Work Platform 7 2...

Page 87: ...Illustrated Parts Breakdown Section 7 9 AB38 Work Platform 7 2...

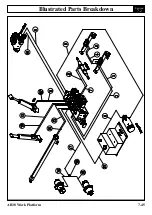

Page 89: ...Illustrated Parts Breakdown Section 7 11 AB38 Work Platform 7 2 22...

Page 91: ...Illustrated Parts Breakdown Section 7 13 AB38 Work Platform 7 2...

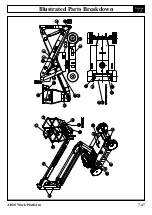

Page 93: ...Illustrated Parts Breakdown Section 7 15 AB38 Work Platform 7 2...

Page 95: ...Illustrated Parts Breakdown Section 7 17 AB38 Work Platform 7 2...

Page 97: ...Illustrated Parts Breakdown Section 7 19 AB38 Work Platform 7 2...

Page 99: ...Illustrated Parts Breakdown Section 7 21 AB38 Work Platform 7 2...

Page 101: ...Illustrated Parts Breakdown Section 7 23 AB38 Work Platform 7 2...

Page 103: ...Illustrated Parts Breakdown Section 7 25 AB38 Work Platform 7 2...

Page 105: ...Illustrated Parts Breakdown Section 7 27 AB38 Work Platform 7 2...

Page 107: ...Illustrated Parts Breakdown Section 7 29 AB38 Work Platform 7 2...

Page 109: ...Illustrated Parts Breakdown Section 7 31 AB38 Work Platform 7 2...

Page 111: ...Illustrated Parts Breakdown Section 7 33 AB38 Work Platform 7 2...

Page 113: ...Illustrated Parts Breakdown Section 7 35 AB38 Work Platform 7 2...

Page 115: ...Illustrated Parts Breakdown Section 7 37 AB38 Work Platform 7 2...

Page 117: ...Illustrated Parts Breakdown Section 7 39 AB38 Work Platform 7 2...

Page 119: ...Illustrated Parts Breakdown Section 7 41 AB38 Work Platform 7 2 8 9...

Page 121: ...Illustrated Parts Breakdown Section 7 43 AB38 Work Platform 7 2...

Page 123: ...Illustrated Parts Breakdown Section 7 45 AB38 Work Platform 7 2...

Page 125: ...Illustrated Parts Breakdown Section 7 47 AB38 Work Platform 7 2...

Page 127: ...Illustrated Parts Breakdown Section 7 49 AB38 Work Platform 7 2...

Page 131: ...Illustrated Parts Breakdown Section 7 53 AB38 Work Platform 7 2 NOTES...

Page 133: ...Technician s Print AB38 Work Platform Electrical Schematic...