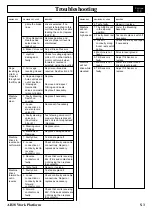

Troubleshooting

Section

5-2

AB38 Work Platform

PROBLEM

PROBABLE CAUSE

REMEDY

PROBLEM

PROBABLE CAUSE

REMEDY

All functions 1. Blown Electric

Check fuses,

inoperable.

Fuse.

Replace if blown.

Electric

2. Faulty Battery

Check the voltage output of

motor does

Charger.

battery charger. If less than

not start.

24 VDC, repair or replace.

3. Faulty Battery or

After completely charging

Batteries.

batteries test each battery.

Replace as required.

4. Loose or broken

Check continuity of all

Battery Lead.

battery and motor leads.

Replace if necessary.

5. Emergency Stop

With emergency stop

Switch(es)

switch in the ON position,

upper & lower

check continuity across

failed open.

contacts. If none, replace.

6. Connecting Plug

Check connection and retry.

at Upper Control

Box loose.

7. Battery Line

Check for security of

Disconnect plug

connection and retry.

loose.

All functions 1. Oil level in

Check hydraulic fluid level,

inoperable.

Hydraulic

as required.

Electric

Reservoir is low.

motor starts 2. Faulty Hydraulic

Check pressure and

when

Pump.

delivery of the hydraulic

control is

pump. Replace if required.

actuated.

3. Faulty

Check operation. Replace

Controller.

if required.

Electric

1. Line Contactor

Replace Line Contactor.

motor

(LC1) contacts

continues to

fused together.

run after

functions

have

ceased.

Platform will 1. Emergency

Remove and inspect the

not elevate

Lowering valve

valve. Replace if necessary.

or elevates

leaking.

slowly.

2. Platform

Observe maximum load

Overloaded.

rating. (See Table 1-1).

3. Faulty Lift Valve

Test Lift Solenoid, if proper

Solenoid.

voltage is present and coil

(Fault code :

unmagnetized - Replace

51 or 53)

the Solenoid.

4. Faulty Controller

Check functionality of

at upper

controller. Replace the

controls.

Controller if faulty.

5. Battery Voltage.

Check Battery Voltage.

Charge if necessary.

Voltage must be greater

than 14V.

Booms drift

1. Emergency

Remove and inspect the

down after

Lowering Valve

valve. Replace if necessary.

being

is leaking.

elevated.

2. Leaking piston

Check for leakage at

seals in Lift

cylinder return line, replace

Cylinders (CYL1, the seal kit if necessary.

CYL2 &

Telescope).

3. Overcentre Valve

Check for contamination

leaking

and clean. Check that

internally or

O-Rings are intact. Adjust

needs adjusting. or replace.

4. Platform

Remove excess weight.

Overloaded.

Machine

1. The Elevating

Raise the Elevating

will not

Assembly is not

Assembly.

slew when

clear of the

Booms are

wheels.

elevated.

2.Faulty Controller

Test Controller for

continuity during Slew

function. Replace if

defective.

3. Faulty Slew

Test Slew Solenoid, if

Solenoid.

proper voltage is present

(Fault code :

and coil is not magnetized

57 or 58)

- Replace

4. Mechanical

Inspect all slewing

Damage.

components. Replace

damaged parts.

5. Slew Valve

Inspect slew valve. If

stuck.

spool is sticking - Replace.

6. Faulty function

Replace switch.

select Switch.

Platform

1.Faulty Down

Test Down Valve Coil. If

will not

Valve Coil

proper voltage is present

lower.

(Fault code :

and coil is not magnetised

52 or 54)

- Replace

2.Faulty function

Replace switch.

Selector Switch.

3.Faulty Controller

Replace if required.

4.Down Valve

Check and see if spool is

stuck.

stuck. - Replace if

necessary.

Telescopic

1.Faulty Tele-Out

Test Tele-out Valve Coil. If

cylinder will

Valve Coil.

proper voltage is present

not extend.

(Fault code :

and coil is not magnetised

55 or 56)

- Replace.

2.Faulty function

Replace switch.

Selector Switch.

3.Faulty Controller.

Replace if required.

4.Tele-Out Valve

Check and see if spool is

stuck.

stuck. - Replace if

necessary.

5.Platform is

Reduce the load

overloaded.

Machine

1. Fuses blown.

Check fuses and replace if

will not

necessary

drive.

2. Loose electrical

Check all electrical

connection on

connections relating to the

drive motor or

drive system for security.

motor control

units.

3. Brakes engaged Check that coil of V2 is

Brake solenoid

energised when drive is

V2 ( CT12 ) has

selected. Remove

become

cartridge and check for

de-energised or

contamination and freedom

the spool is

of movement of the

stuck in the open spool. Replace if

position.

necessary.

4. Brakes engaged Check that the coil of V1

Brake solenoid

is energised for

V1 ( CT11 ) is not approximately 4 seconds,

energising to

by a delay module, when

5.1

Summary of Contents for AB38

Page 2: ...ii AB38 Work Platform NOTES...

Page 4: ...ii AB38 Work Platform NOTES...

Page 6: ...iv AB38 Work Platform NOTES Foreword...

Page 10: ...Contents Section IV AB38 Work Platform i NOTES...

Page 14: ...Introduction Specifications Section 1 4 AB38 Work Platform NOTES 1 3...

Page 17: ...Machine Preparation Section 2 3 AB38 Work Platform NOTES 2 7...

Page 18: ...Machine Preparation Section 2 4 AB38 Work Platform 2 7 NOTES...

Page 29: ...Operation Section 3 11 AB38 Work Platform NOTES 3 5...

Page 30: ...Operation Section 3 12 AB38 Work Platform NOTES 3 5...

Page 59: ...Maintenance Section 4 29 AB38 Work Platform NOTES 4 21...

Page 60: ...Maintenance Section 4 30 AB38 Work Platform NOTES 4 21...

Page 66: ...Troubleshooting Section 5 6 AB38 Work Platform 5 7 NOTES...

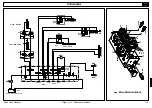

Page 68: ...Schematics Section 6 2 AB38 Work Platform NOTES 6 0...

Page 72: ...Schematics Section 6 6 AB38 Work Platform 6 1 NOTES...

Page 73: ...Electrical Schematic Schematics 6 7 AB38 Work Platform Section 6 1...

Page 74: ...Electrical Schematic Schematics 6 8 AB38 Work Platform Section 6 1 TOP VIEW...

Page 76: ...Schematics Section 6 10 AB38 Work Platform NOTES 6 2...

Page 78: ...Section 6 2 6 12 AB38 Work Platform Schematics NOTES...

Page 81: ...Illustrated Parts Breakdown Section 7 3 AB38 Work Platform 7 2...

Page 83: ...Illustrated Parts Breakdown Section 7 5 AB38 Work Platform 7 2...

Page 85: ...Illustrated Parts Breakdown Section 7 7 AB38 Work Platform 7 2...

Page 87: ...Illustrated Parts Breakdown Section 7 9 AB38 Work Platform 7 2...

Page 89: ...Illustrated Parts Breakdown Section 7 11 AB38 Work Platform 7 2 22...

Page 91: ...Illustrated Parts Breakdown Section 7 13 AB38 Work Platform 7 2...

Page 93: ...Illustrated Parts Breakdown Section 7 15 AB38 Work Platform 7 2...

Page 95: ...Illustrated Parts Breakdown Section 7 17 AB38 Work Platform 7 2...

Page 97: ...Illustrated Parts Breakdown Section 7 19 AB38 Work Platform 7 2...

Page 99: ...Illustrated Parts Breakdown Section 7 21 AB38 Work Platform 7 2...

Page 101: ...Illustrated Parts Breakdown Section 7 23 AB38 Work Platform 7 2...

Page 103: ...Illustrated Parts Breakdown Section 7 25 AB38 Work Platform 7 2...

Page 105: ...Illustrated Parts Breakdown Section 7 27 AB38 Work Platform 7 2...

Page 107: ...Illustrated Parts Breakdown Section 7 29 AB38 Work Platform 7 2...

Page 109: ...Illustrated Parts Breakdown Section 7 31 AB38 Work Platform 7 2...

Page 111: ...Illustrated Parts Breakdown Section 7 33 AB38 Work Platform 7 2...

Page 113: ...Illustrated Parts Breakdown Section 7 35 AB38 Work Platform 7 2...

Page 115: ...Illustrated Parts Breakdown Section 7 37 AB38 Work Platform 7 2...

Page 117: ...Illustrated Parts Breakdown Section 7 39 AB38 Work Platform 7 2...

Page 119: ...Illustrated Parts Breakdown Section 7 41 AB38 Work Platform 7 2 8 9...

Page 121: ...Illustrated Parts Breakdown Section 7 43 AB38 Work Platform 7 2...

Page 123: ...Illustrated Parts Breakdown Section 7 45 AB38 Work Platform 7 2...

Page 125: ...Illustrated Parts Breakdown Section 7 47 AB38 Work Platform 7 2...

Page 127: ...Illustrated Parts Breakdown Section 7 49 AB38 Work Platform 7 2...

Page 131: ...Illustrated Parts Breakdown Section 7 53 AB38 Work Platform 7 2 NOTES...

Page 133: ...Technician s Print AB38 Work Platform Electrical Schematic...