3-4

SL26/30SL Work Platform

M

AINTENANCE

Section

3.6

Battery Charging

The battery is charged by the alternator whenever

the engine is running and should not require any

other charging. If the machine has not been in ser-

vice or if for some other reason the battery has been

discharged, perform the following:

Check the battery fluid level. If the electrolyte level is

lower than 10 mm (3/8 in.) above the plates, add

clean, distilled water only.

Battery Specific Gravity

After charging, if necessary, the specific gravity of all

cells should be checked with a hydrometer. The tem-

perature corrected specific gravity should be 1.260. If

the battery contains any cells with corrected readings

below 1.230, the battery should be replaced.

Do not check the specific gravity in a cell to which

water has just been added. If there is not enough

electrolyte in a fully charged cell to obtain a sample

for the hydrometer, add water and continue charging

for 1 to 2 hours to adequately mix the water and elec-

trolyte.

3.6 L

UBRICATION

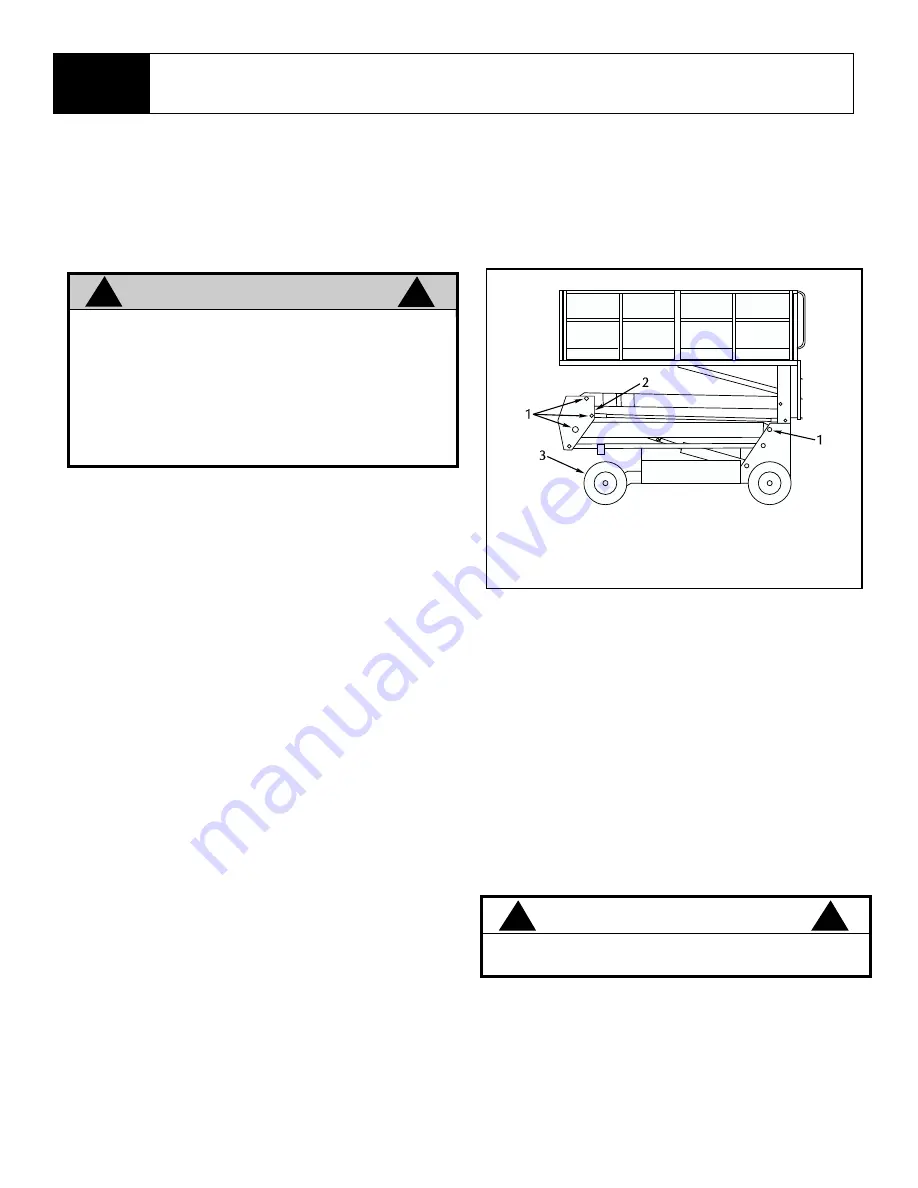

Refer to Table 3-1 for lubrication intervals and

Figure 3-2 for location of items that require lubrica-

tion service. Refer to the appropriate sections for

lubrication information on the hydraulic tank and filter.

Figure 3-2: Lubrication Points

Grease Fittings

Wipe each grease fitting before and after greasing.

Using multipurpose grease in a grease gun, pump

the grease into the fitting until grease just begins to

appear at the edges of the pivot, wipe off any excess

grease.

Linkage Gears

1. Raise platform fully.

2. Using another work platform or ladder, get up

high enough to comfortably reach gears.

3. Use a long handled brush to apply multipurpose

grease to the face of the gears.

4. Lower the platform after greasing.

Steering Linkage

Apply one or two drops of motor oil to each pivot and

king pin bearing.

W A R N I N G

!

!

Charge the battery only in a well ventilated

area.

Do not charge the battery when the work plat-

form is in an area containing sparks or flames.

Always follow the charger manufacturer instruc-

tions.

Never disconnect the cables from the batteries

when the charger is operating.

C A U T I O N

!

!

Do not use hands to apply grease or allow any

body part to enter the elevating assembly.

1. Grease Fittings

2. Linkage Gears

3. Steering Linkage

Summary of Contents for SL26SL

Page 1: ...European Specification ...

Page 4: ...ii SL26 30SL Work Platform FORWARD NOTES ...

Page 12: ...1 4 SL26 30SL Work Platform INTRODUCTION SPECIFICATIONS Section 1 3 NOTES ...

Page 24: ...2 12 SL26 30SL Work Platform MACHINE PREPARATION OPERATION Section 2 13 NOTES ...

Page 48: ...4 6 SL26 30SL Work Platform TROUBLESHOOTING Section 4 2 NOTES ...

Page 54: ...5 6 SL26 30SL Work Platform SCHEMATICS Section 5 2 NOTES ...

Page 59: ...SL26 30SL Work Platform 6 5 ILLUSTRATED PARTS BREAKDOWN 6 1 NOTES ...

Page 63: ...SL26 30SL Work Platform 6 9 ILLUSTRATED PARTS BREAKDOWN 6 1 NOTES ...

Page 65: ...SL26 30SL Work Platform 6 11 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 67: ...SL26 30SL Work Platform 6 13 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 69: ...SL26 30SL Work Platform 6 15 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 71: ...SL26 30SL Work Platform 6 17 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 83: ...SL26 30SL Work Platform 6 29 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 85: ...SL26 30SL Work Platform 6 31 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 95: ...SL26 30SL Work Platform 6 41 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 97: ...SL26 30SL Work Platform 6 43 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 99: ...SL26 30SL Work Platform 6 45 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 101: ...SL26 30SL Work Platform 6 47 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 103: ......