3-6

SL26/30SL Work Platform

M

AINTENANCE

Section

3.7

3.7 S

ETTING

H

YDRAULIC

P

RESSURES

Referring to Figure 3-13 along with the other Figures

will aid in the following procedures.

Note: Check the hydraulic pressures whenever

the pump, manifold, or relief valve(s) have been

serviced or replaced.

Main Relief Valve (Figure 3-4)

1. Operate the hydraulic system for five minutes.

2. Remove the gauge port plug (Figure 3-5) and

install a quick disconnect gauge assembly.

3. Remove the plug in the end of the main relief

valve to expose the adjusting screw.

4. Remove the hex nut holding the lift coil onto the

lift valves and remove coil.

5. With the engine running, use the chassis lift

switch to elevate the platform, hold until the sys-

tem bypasses (approximately 2 seconds).

6. While holding the chassis lift switch in the

UP

position, set the pressure to 172 bar (2500 psi)

maximum by slowly turning the adjusting screw,

clockwise increases pressure.

7. Reinstall the coil on the lift valve.

8. Remove the pressure gauge and reinstall all

plugs.

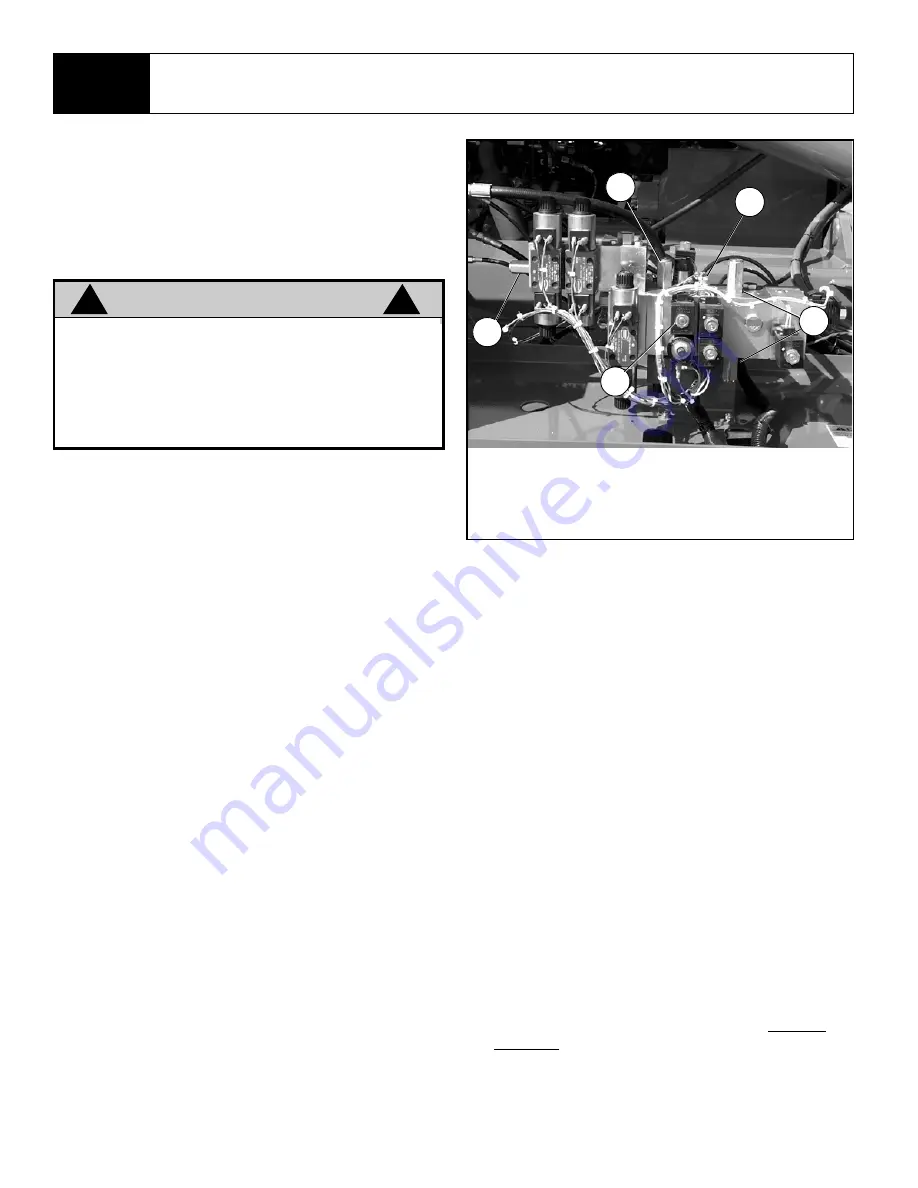

Figure 3-4: Hydraulic Manifold Assembly, Front View

Counterbalance Valves (Figure 3-4)

1. Operate the hydraulic system for five minutes to

warm the oil.

2. Remove the quick disconnect plug (Figure 3-5)

and install a 0-41 bar (0-600 psi) pressure gauge

assembly.

3. Exchange the top Counterbalance Valve with the

Main Relief Valve.

4. Remove the plug from the end of the Counterbal-

ance Valve to expose the adjusting screw.

5. Remove the hex nut holding the lift coil onto the

lift valve and remove the coils.

6. With the engine running, use the chassis lift

switch to elevate the platform, hold until the sys-

tem bypasses (approximately 2 seconds).

7. While holding the chassis lift switch in the

UP

position, set the pressure to 34.5 bar (500 psi)

maximum by slowly turning the adjusting screw,

clockwise increases pressure.

8. Exchange the top Counterbalance Valve with the

bottom Counterbalance Valve and repeat the pro-

cedure.

9. Be sure to reinstall the valves to their original

locations and replace all plugs when finished set-

ting pressures.

W A R N I N G

!

!

The hydraulic oil may be of sufficient tempera-

ture to cause burns. Wear safety gloves and

safety glasses when handling hot oil.

The oil in the hydraulic system is under very

high pressure which can easily cause severe

cuts. Obtain medical assistance

immediately

if

cut by hydraulic oil.

1

2

3

4

1. Main Relief Valve

2. Counterbalance

Valves

3. Lift Coil

4. Steering Relief

Valve

5. Quick Disconnect

5

Summary of Contents for SL26SL

Page 1: ...European Specification ...

Page 4: ...ii SL26 30SL Work Platform FORWARD NOTES ...

Page 12: ...1 4 SL26 30SL Work Platform INTRODUCTION SPECIFICATIONS Section 1 3 NOTES ...

Page 24: ...2 12 SL26 30SL Work Platform MACHINE PREPARATION OPERATION Section 2 13 NOTES ...

Page 48: ...4 6 SL26 30SL Work Platform TROUBLESHOOTING Section 4 2 NOTES ...

Page 54: ...5 6 SL26 30SL Work Platform SCHEMATICS Section 5 2 NOTES ...

Page 59: ...SL26 30SL Work Platform 6 5 ILLUSTRATED PARTS BREAKDOWN 6 1 NOTES ...

Page 63: ...SL26 30SL Work Platform 6 9 ILLUSTRATED PARTS BREAKDOWN 6 1 NOTES ...

Page 65: ...SL26 30SL Work Platform 6 11 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 67: ...SL26 30SL Work Platform 6 13 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 69: ...SL26 30SL Work Platform 6 15 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 71: ...SL26 30SL Work Platform 6 17 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 83: ...SL26 30SL Work Platform 6 29 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 85: ...SL26 30SL Work Platform 6 31 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 95: ...SL26 30SL Work Platform 6 41 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 97: ...SL26 30SL Work Platform 6 43 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 99: ...SL26 30SL Work Platform 6 45 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 101: ...SL26 30SL Work Platform 6 47 ILLUSTRATED PARTS BREAKDOWN 6 1 ...

Page 103: ......