Page 3-17

Maintenance

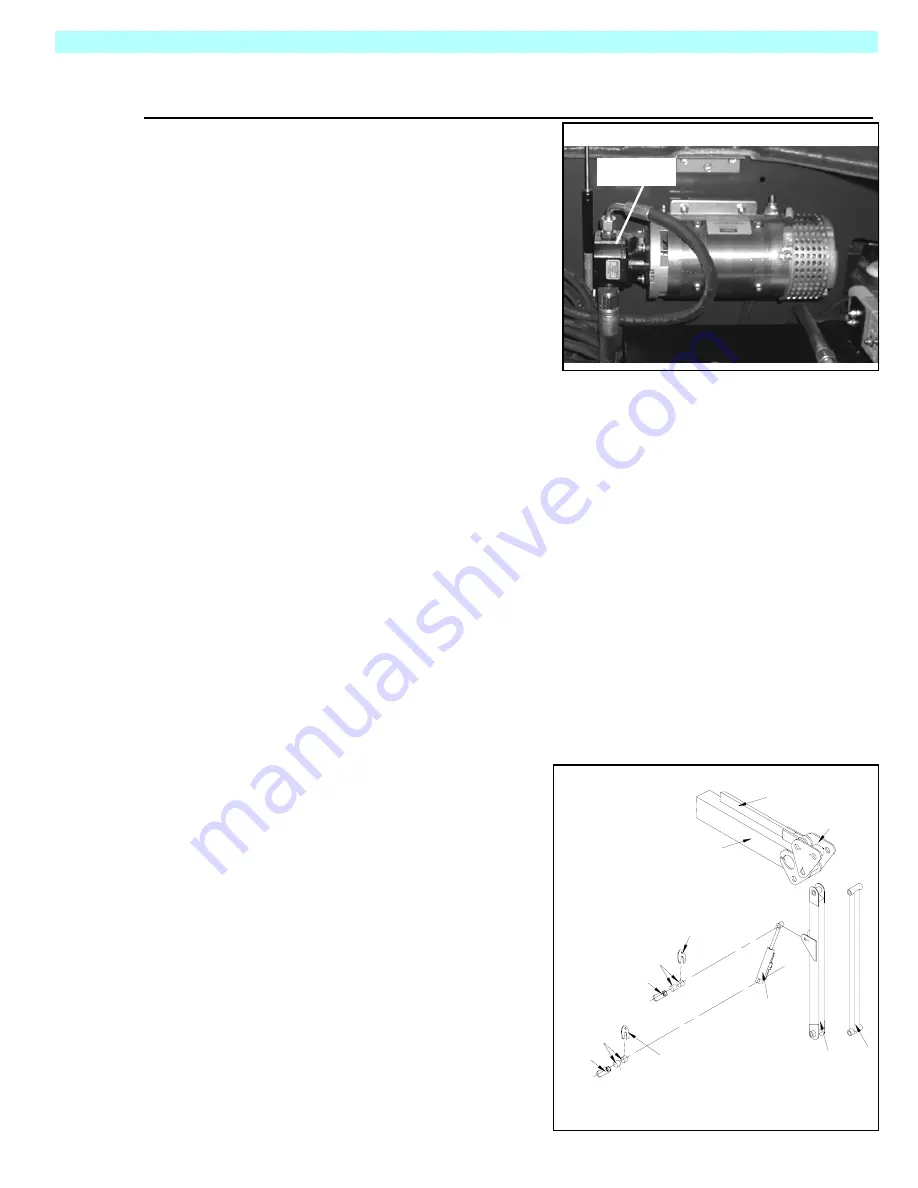

3.10 - Hydraulic Pump

TL38 Service & Parts

3.10 H

YDRAULIC

P

UMP

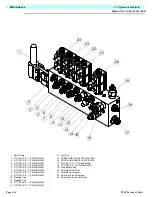

Figure 3-6:

Hydraulic Pump

R

EMOVAL

NOTE:

If the hydraulic tank has not been drained,

suitable means for plugging the hoses should be

provided to prevent excessive fluid loss.

1. Mark, disconnect, and plug the hose

assemblies.

2. Loosen the capscrews and remove the

pump assembly from the motor.

I

NSTALLATION

1. Lubricate the pump shaft with general pur-

pose grease and attach the pump to the

motor with the capscrews.

2. Using a criss-cross pattern torque each capscrew a little at a time until all of the capscrews

are torqued to 27 Nm (20 Ft/lbs).

3. Unplug and reconnect the hydraulic hoses.

4. Check the oil level in the hydraulic tank before operating the work platform.

3.11 H

YDRAULIC

C

YLINDER

(J

IB

)

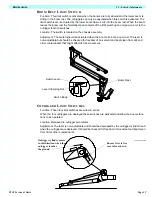

Note : Removal of the Jib cylinder requires the cage to be held in position by suitable sup-

port slings.

R

EMOVAL

1. Disconnect both hoses and plug ends to avoid excessive oil spillage. Note which hose goes to

which port.

2. Remove lock plate securing bolt and spring washer from both the rod end pin and body end

pin.

3. Remove lock plates.

4. Hold cage assembly in position and knock out rod end pin and body end pin.

5. Remove cylinder.

I

NSTALLATION

1. Lift the cylinder into place and insert the

body end pin in through the cylinder and boom.

Note: take care in aligning the pin in the

holes so that the pin can be pushed in by

hand. If the pin and holes are not properly

aligned and the pin is forced in, the bush-

ings will be damaged.

2. Line the holes up with the cylinder rod hole

and insert the rod end pin.

3. Slide both locking plates into the groves on

the pins and secure with the bolts and wash-

ers.

4. Test with weight at rated platform load to

check system operation.

PUMP

1

2

5

6

7

8

9

3

4

7

8

9

1. Levelling Rod

2. Upper Boom

3. Jib Link Weldment

4. Jib Weldment

5. Jib Tie Bar

6. Jib Cylinder

7. Pin Lock Plate

8. Bushings

9. Pins

Summary of Contents for TL38

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL38 ...

Page 2: ......

Page 4: ......

Page 51: ...Page 3 28 Maintenance 3 17 Torque Specifications TL38 Service Parts NOTES ...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL38 Service Parts ...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL38 Service Parts ...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL38 Service Parts ...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL38 Service Parts ...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL38 Service Parts Notes ...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL38 Service Parts ...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL38 Service Parts ...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly TL38 Service Parts ...

Page 84: ...Page 6 21 Illustrated Parts Breakdown Outrigger Cylinder Assembly TL38 Service Parts NOTES ...

Page 86: ...Page 6 23 Illustrated Parts Breakdown Electrical Assembly TL38 Service Parts ...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Decal Assembly TL38 Service Parts ...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL38 Service Parts ...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL38 Service Parts NOTES ...