Check all fit

tings and hoses for leaks. In

spect

hoses for signs of dam age from chaff ing or rub bing

against pro tru sions on the chas sis or scis sor stack.

Figure 7.15 - Check Hydraulic Cylinders

Pay par tic u lar at ten tion to the cyl in ders, check to

see that there is no oil leak ing from the seal, also

check all hoses that run to the cyl in ders.

Have a qual i fied trained main te nance per son re -

pair all hy drau lic fluid leaks be fore you op er ate an

RT

.

■

Tires and Wheels

RT

tires are foam filled. Punc tures of the type

caused by bolts, screws, or nails are not a prob lem.

Look for large holes or long cuts com

pletely

through the tire body: holes or cuts where foam is

be ing forced or eroded out of the tire.

Also look for large im bed ded ob jects, such as an -

gle iron, that can rip a tire body open un der some

con di tions.

■

Bolts and Fasteners

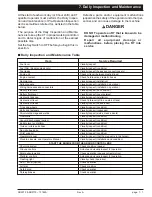

Figure 7.16 - Bolts and Fasteners

Vi su ally in spect all fas ten ers to see that none are

miss ing or ob vi ously loose.

Figure 7.17 - Critical Pin Retainer Bolts

Crit i cal pin re tainer bolts have lock tab wash ers fit -

ted, they should all be pres ent and not dam aged in

any way.

Figure 7.18 - Wheel Nuts

Pay par tic u lar at ten tion to all of the wheel nuts.

None should be vis

i

bly loose, miss

ing, or de

-

formed.

A de cal is at tached to each wheel rim giv ing the

cor rect torque set tings for the wheel nuts, see yel -

low ar row.

The correct torque setting for the SR3370 /

SR2770 wheel nuts is 90 - 100 lb ft or 122 - 135

Nm. Do not tighten beyond these settings.

Do not over tighten wheel nuts. Over

tightened wheel nuts can damage or deform

the wheel rim. This could lead to stability

problems.

SR3370 & SR2770 – 13184A

Rev A

page 7 - 5

7. Daily Inspection and Maintenance

0372061

TORQUE

·

90-100 Ft. Lbs.122-135 N m

Lug Bolts/Nuts

Check Every 30 Days

CAUTION

IMPORTANT