Figure 7.11 - Wiring Harness in the Scissor

Stack

Pay par tic u lar at ten tion to the wir ing har nesses

that are at tached to the scis sor stack. Note that the

wire har ness runs with the main hose bundle.

■

Battery Terminals

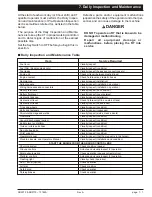

Figure 7.12 - Battery Terminals

Bat tery ter mi nals should be clean and free of cor ro -

sion and the bat tery leads firmly at tached.

❑

Battery Fluid Level

Batteries emit hydrogen and oxygen,

elements that can combine explosively.

Death or serious injury can result from a

chemical explosion.

DO NOT

smoke or per mit open flames or sparks

when check ing bat ter ies.

Note

Units manufactured in New Zealand are typically

fit ted with a "main te nance free" bat tery.

If your unit is not fit ted with sucha bat tery you will

need to do the fol low ing.

Remove the caps from the battery and visually

check to see that the battery fluid is 1/4 (6 mm)

below the bottom of the filler neck inside each hole

■

Hydraulic Oil Tank

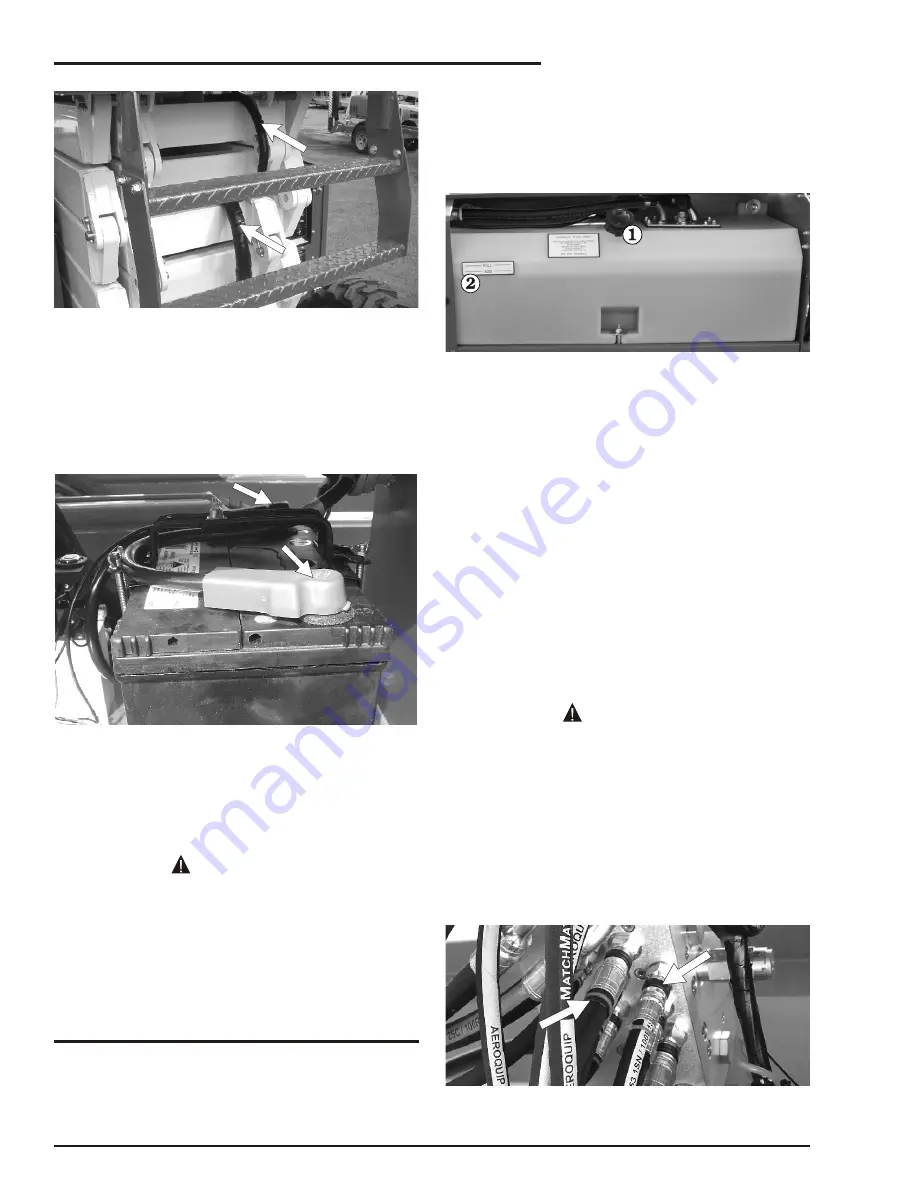

Figure 7.13 - Hydraulic Oil Tank

❑

Hydraulic tank cap

Check to see that the cap

is in place and is tight

(see Fig ure 7.13).

❑

Hydraulic oil level

To check the hy drau lic oil level:

Com pletely lower the plat form. The hy drau lic oil

level should be at the full level ac cord ing to the

gauge

(see Fig ure 7.13) . If nec es sary, add hy -

drau lic oil at the Hy drau lic oil tank cap. See the

Spec i fi ca tions chap ter for type and grade of hy -

drau lic oil.

■

Hydraulic Oil Leaks

Leaking hydraulic oil can cause burns, fires,

falls (slipping), cuts, and puncture wounds

(if under high pressure). Do not tolerate

hydraulic oil leaks. They are dangerous.

Do not search for leaks with your hand, use a piece

of card board or wood. Hy drau lic oil leaks are eas ily

vis i ble and can show up any place. Vi su ally in spect

the en

tire ma

chine for hy

drau

lic oil. Check the

ground un der the ma chine for leaked oil.

Figure 7.14 - Check Fittings at Valve

page 7 - 4

Rev A

SR3370 & SR2770 – 13184A

7. Daily Inspection and Maintenance

DANGER

DANGER