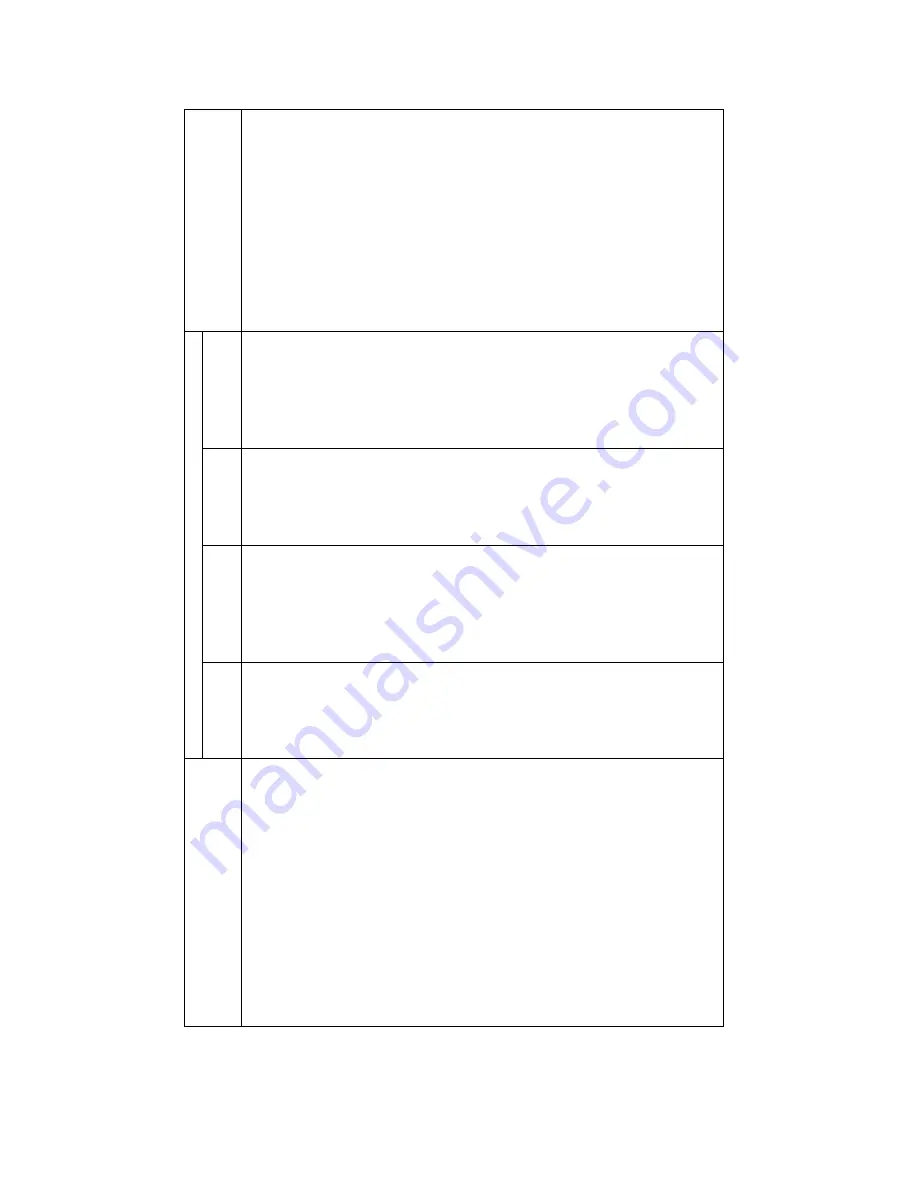

T

able 5

Maximum

T

olerated Limits of

W

ear

and Clearances Between Principal Mating Members of the Engine, mm

Maximum tolerances

Name of parts and mated pairs of parts

wear

on

diameter

out

-of

-r

ound and

taper

diameter

clearance

axial clearance

Measuring point and method

Crankpin to rol

le

rs to connecting rod big end

0.100

Crankpin

0.050

Connecting

- rod big end

0.050

Cylinder (face)

0.150

Out

-of

-round

0.070

In five po

ints (refer to

"Repairing the Crank Mechanism

”

of sub

section 2)

Cylin

der to piston

—

—

0.200

Measure piston

in plane, square to pin

axis at point

5

mm from the piston

lo

wer edge

Piston pin

0.015

Hole in piston to fit pin

0.020

Piston to piston pin

0.010

Connecting rod small end bush

0.02

5

Piston pin to connecting

rod small end bush

0.030

Compression ring (height)

0/050

Piston groove to piston ring

0.150

(by

depth)

'Piston groove to oil control ring

0.150

(by depth)

V

alve stem

0.120

V

alve guiding bush

0

.150

V

alve stem to

0.250

Guiding bush

0

.150

Rockshaft

0.070

Rocking arm

(aperture)

0.070

Rockshaft to rock

ing arm

0.120

T

appet

0.050

T

appet guide

0.050

T

appet to tappet

guide

0.100

45

Summary of Contents for 750cc Series

Page 1: ...Repair Manual 750cc All Models www imz ural com ...

Page 2: ......

Page 71: ...1 2 3 4 5 6 7 8 Fig 66 Final drive 71 ...

Page 98: ...Fig 11 iring Diagram 9 W 98 ...