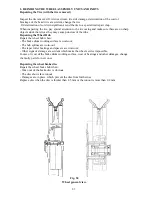

- insert a portion of the tire bead into the rim well and use the tire irons to slip the hole bead

inside, moving it towards the rim shoulder;

- insert the inner tube valve into the hole in the rim, insert the slide valve into the tube valve,

inflate the tube slightly and insert it into the tire casing, making sure that it is spread uniformly

without any wrinkles;

- fit on the second tire bead, beginning from the side opposite to the valve. Make sure that the

first tire bead is settled in the rim well properly. Usually about two thirds of the bead are fitted in

with hands, while the rest, with the help of tire irons.

When using irons, take care not to pinch and injure the inner tube; to facilitate mounting smear

the tire bead with liquid soap.

Having mounted the tire bead, make the valve sink into the tire casing, inflate the inner tube and

tap with a rubber hammer along the tire circumference until the tire is set uniformly in the rim

well.

Inflate the tube to the required pressure, turn on the valve and screw on the valve cap.

Tires pressure, Mpa :

Front wheel and side-car wheel .......

35psi

Rear wheel and spare wheel ....…...

40psi

Check the proper arrangement of the tire on the rim (the check strips should be equidistant from

the rim along the entire periphery of the tire).

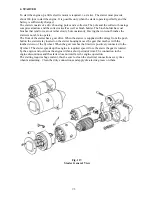

Dismantling and Reassembling the Wheel Hub

(with the wheel removed)

The required tool is mandrel 345-324-3 for removing the roller bearing cup.

To dismantle the wheel hub:

- Loosen locknut, undo the seal nut and remove the left-hand distance bushing;

- Insert the mandrel or the wheel axle on the side of the hub splined portion and press the end

roller bearing, the intermediate bushing, the cone of the second roller bearing and the right-hand

distance bushing out of the wheel hub;

- Using mandrel 345-324-3 presses out the thrust washer and the roller bearing cup.

Wash and inspect the dismantled parts. Change all the defective parts. Reassemble the wheel hub

as follows:

- Fit the thrust washer and the right-hand distance bushing into the hub inserting the shoulder of

the latter into the thrust washer groove;

- Press in the roller bearing, having packed it first with grease Litol-24 so that the wider side of

the cup faces the thrust washer, with the bearing pressing against the washer;

- Insert the intermediate bushing;

- Press in the second roller bearing (also packed with grease Litol-24 so that

the wider side of the

cup faces the oil seal nut (outside):

- Press the rubber collar into the oil seal nut arranging it so that the oil catching edge and the

spring are inside the nut;

- Insert the left-hand bushing into the seal nut from the side facing the bearing, turn in the nut to

the limit, thus tightening the bearings properly;

- Turn off the nut by 1/6 to 1/8 of a revolution and lock with a locknut. The tightening torque

should be 14

.

7

-

17

.

6 Nm.

After reassembling, check the bearings for proper tightening and adjust, if necessary. To perform

this check:

- Insert the rear wheel axle into the reassembled wheel hub, and tighten up all the cones and cups

on the axle with the help of the nut with a set of bushings;

- By turning and rocking the wheel

axle, make sure that it

Turns freely, with neither noticeable play nor squeaks in the bearings. Unscrew the locknut and

adjust it for proper tightening, if necessary.

Remember that overtightening of bearings or excessive play are harmful as they lead to

premature wear of bearings.

With a properly assembled hub, the left-hand distance bushing should protrude from the rubber

collar within 1

.

0

-

2

.

0 mm. If otherwise, change the faulty bushing.

82

Summary of Contents for 750cc Series

Page 1: ...Repair Manual 750cc All Models www imz ural com ...

Page 2: ......

Page 71: ...1 2 3 4 5 6 7 8 Fig 66 Final drive 71 ...

Page 98: ...Fig 11 iring Diagram 9 W 98 ...