13

E N G L I S H •

User’s manual

3. Step on the left side of PEDAL until hear a

“click”, then turn on the WHEEL HANDLE on the

top of the machine to remove the equipment

forward and reverse, step down the right side of

PEDAL to change to “push” driving system.

4. Lower blade into cut slowly.

5. Cut as fast as blade will allow. If blade climbs

out of cut, reduce forward speed or depth of cut.

6. Use only enough side pressure on cutter han-

dles to follow cutting line.

CUTTING

Lower the blade into concrete to required

depth by turning the tilt crank counterclock-

wise. Ease the saw slowly forward. Slow for-

ward pressure if the saw begins to stall.

NOTE: For deeper cuts (4 inches / 102mm or

more), several cuts should be made in incre-

mental steps of 1-1/2 inch (38 mm) to 2 inches

(51 mm) until the desired depth is reached.

• Push the saw steadily forward using the front

pointer as a guide. Exert enough forward pres-

sure so that the engine/motor begins to labor,

but does not slow down. If the saw begins to

stall, retard forward movement until full RPM

is restored to the blade. If saw stalls, raise the

blade out of the cut before restarting. Avoid

excessive side pressure or twisting of the blade

in the cut.

BELTS & PULLEYS

NEVER MAKE ADJUSTMENTS TO V-BELTS AND

PULLEYS WHILE ENGINE IS RUNNING

1. The best tension for a v-belt drive is the low-

est tension at which the belts will not slip un-

der full load.

2. Take up tension until the belts are snug in

the grooves. Run the drive for about five (5)

minutes to “seat” the belts. The impose the

peak load. If the belts slip, tighten them un-

til they no longer slip at peak load. Most new

belts will need additional tensioning after

seating.

3. Remember, too much tension shortens belt

and bearing life.

4. Check the belt tension frequently during the

first day of operation. Check the belt tension

periodically thereafter and make any necessary

adjustments.

5. The two most common causes of sheave mis-

alignment are:

a) The engine drive shaft and the blade shaft

are not parallel.

b) The pulleys are not located properly on the

shafts.

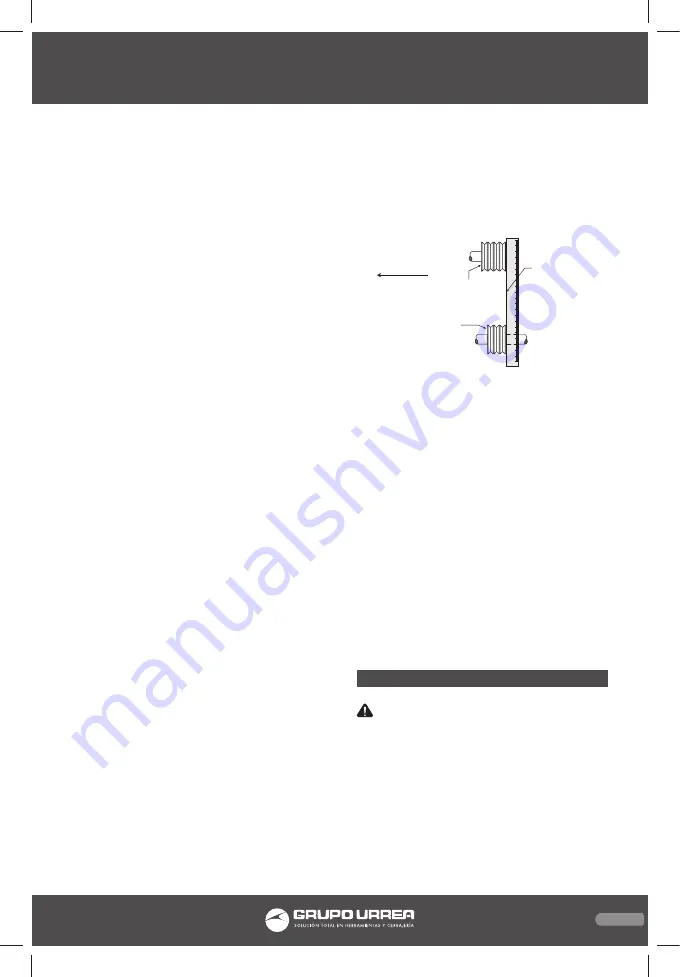

6. To check alignment, use a steel straight edge.

7. Line up the straight edge along the outside face

of both pulleys shown in the drawing. All pulleys

have 2 set screws in the bottom of their grooves.

Set screws require thread locking lock title.

8. Misalignment will show up as a gap between

the pulley face and straight edge. Make sure

there is clearance between arbor pulley and

saw base on both sides.

DRY CUTTING

• Never operate any saw without safety guards

in place.

• Do not exceed maximum operating speed es-

tablished for blade diameter.

• Do not force blade into material: allow blade

to cut at its own speed.

• Do not make long continuous cuts. Never dry

cut for more than 30 seconds at a time. Allow

blade to cool.

• Do not cut or grind with side of blade or cut

a curve or radius. Do not cut dry with blades

recommended for wet cutting.

• Do not operate saw with blade diameter

larger than machine’s capacity.

MAINTENANCE

CARE AND PREVENTIVE MAINTENANCE

CAUTION: Inspection and other services

should always be carried out on hard and level

ground with the engine shutdown.

· NEVER lubricate components or attempt ser-

vice on a running machine.

· ALWAYS allow the machine a proper amount

of time to cool before servicing.

· Keep the machinery in running condition.

· Fix damage to the machine immediately and

always replace broken parts.

Straight

edge

Engine

pulley

To

engine

Blade

shaft pulley

CCO820 manual.indd 13

17/10/17 10:00