14

· Dispose of hazardous waste properly. Exam-

ples of potentially hazardous waste are used

motor oil, fuel and fuel filters.

· DO NOT use food or plastic containers to dis-

pose of hazardous waste.

LUBRICATION AND SERVICE

· Check oil levels, wiring, hoses (air, fuel, water)

and lubricate machine daily.

· Repair or replace all worn or damaged com-

ponents immediately.

· Check drive belt tension, do not over-tension.

· Make sure machine has full set of matched belts.

· Check blade shaft, make sure arbor and

threads are not worn, damaged, or bent.

· Blade shaft, bearings should be tight, no free

play side-to-side or up and down.

· Grease blade shaft bearings daily.

· Blade collars should be clean, free of nicks and

burrs. No diameter wear and not out of round.

· Drive pin not excessively worn or bent and

free of gouges.

· All guards in place and secure

· All fasteners tight and secure.

· Air filter/oil filter (hydraulic or engine) clean.

· Flush clean water through the pump and

spray the assembly every night. This prolongs

the pump and blade life.

IMPORTANT: Never lubricate the compo-

nents or try to give maintenance service while

the machine is running.

· Clean machine before starting lubrication

maintenance.

· Insure machine is on solid, level ground be-

fore starting maintenance.

· During lubrication maintenance insure strict

cleanliness is observed at all times.

· To avoid the risk of accidents, use the correct

tool for the job and keep tools clean.

· The draining of engine oil is best carried out

when the oil is warm NOT hot.

· Any spilled oil must be cleaned up immedi-

ately.

· Use only clean containers for oil and only

CLEAN, FRESH oils and grease of correct grade.

· Contaminated Water/Fluids/Oils/Filters Must

Be Disposed of Safely.

TROUBLESHOOTING

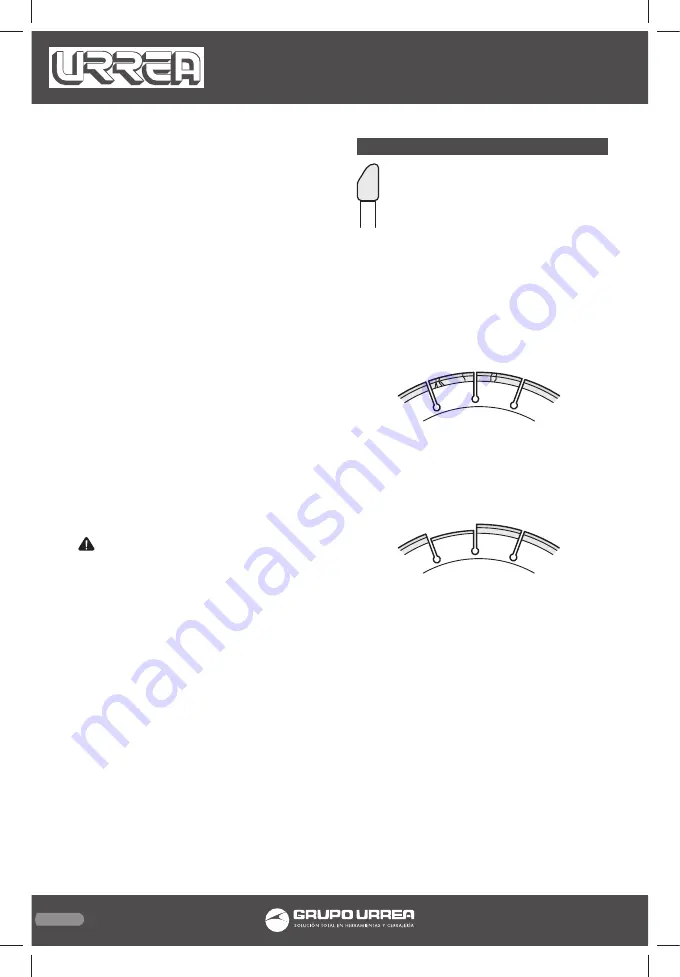

Uneven segment wear.

(in wet cutting) insufficient water(usually

on one side of blade). Flush water system.

Check flow to both sides of blade.

Equipment defects also can cause the

segments to wear unevenly. Replace bad

bearings, worm arbor shaft or misalignment to

spindle.

Saw head is misaligned. Check alignment for

square ness, both vertically and horizontally, of

the saw blade.

Segment cracks.

Blade is too hard for material being cut. Use a

blade with a softer bond/matrix.

Segment loss.

Blade overheats because of lack of coolant

(water or air). (Wet Cutting) check water lines.

Make sure flow is adequate on both sides of

blade and there are no blockages. Use suffi-

cient water to flush out the cut.

Core is worn from undercutting. Dry Cutting)

Run blade free of cut periodically to air cool.

Defective collars/flanges set blade out of

alignment. Clean collars/flanges or replace if

they are under recommended diameter.

Blade is too hard for material being cut. Use

proper blade specification for material being

cut.

Blade is cutting out of round, causing a pound-

ing motion. Replace worn bearings; realign

blade shaft or replace worn blade mount-

ing arbor. When ordering blades match shaft

speed of saw. Check spindle speed to ensure

blade is running at correct RPM.

Improper blade tension. Avoid twisting or

turning blade in the cut.

CCO820 manual.indd 14

17/10/17 10:00