15

E N G L I S H •

User’s manual

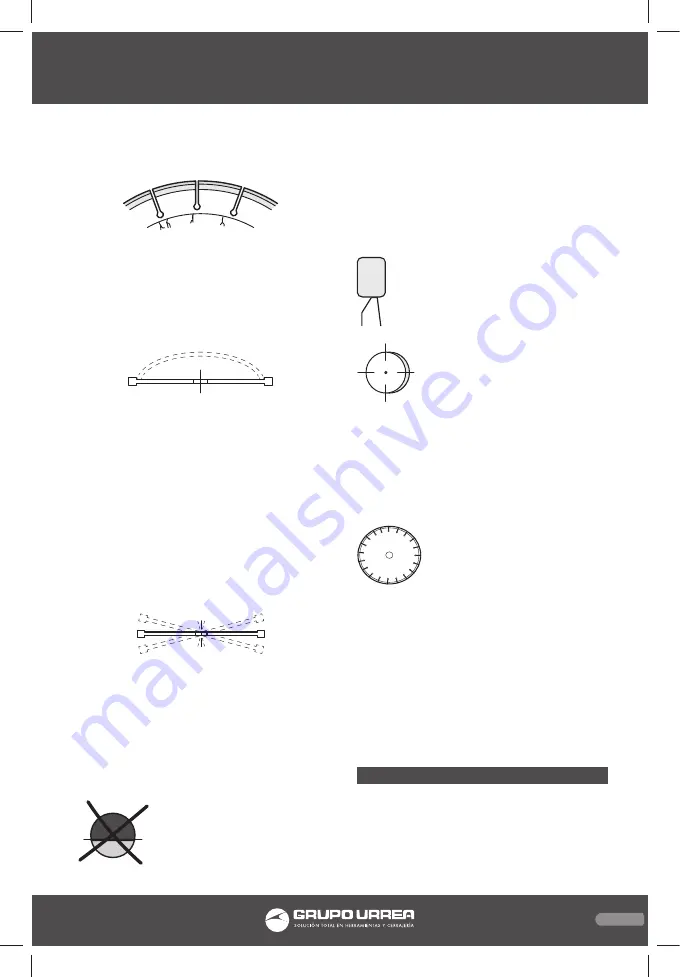

Cracks in core.

Blade flutters in cut as a result of losing blade

tension. Tighten the blade shaft nut.

Blade specification is too hard for the mate-

rial being cut. Make sure blade is running at

proper speed and that drive pin is functioning

properly. Use a softer bond/matrix to eliminate

stress.

Loss of tension.

Core overheating. Make certain blade RPM is

correct.

Core overheating as a result of blade spinning

on arbor. Check water flow, distribution and

lines. Tighten the blade shaft nut.

Core overheating from rubbing the material

being cut. Make certain the drive pin is func-

tioning. Properly align the saw to square cut.

Unequal pressure at blade clamping collars/

flanges. Collars/flanges must be identical in di-

ameter and the recommended size.

Blade is too hard for the material being cut.

Use a softer bond/matrix to reduce stress.

Blade wobbles.

Blade is on a damaged or worn saw. Check for

had bearings, bent shaft, or worm mounting

arbor.

Worn collar. Check collars/flanges to make sure

they are clean, flat and of correct diameter.

Blade runs at an incorrect speed. Set engine at

proper RPM.

Collar/flange diameters are not identical. Use

proper size blade collars/flanges.

Blade is bent as a result of dropping or twist-

ing. DO NOT use bent blade. Contact blade

manufacturer.

Blade will not cut.

Blade is too hard for material

being cut. Select proper blade

for material being cut.

Blade has become dull. Sharpen by cutting on

softer abrasive material to expose diamonds. If

continually sharpening, the blade is too hard

for the material being cut.

Blade does not cut material it was specified

for. Break-in on the material to be cut. If it

does not dress itself, sharpen as you would a

dull blade.

Undercutting the rope.

Abrasive wearing of the core faster

than the segments. Use water to flush

out fines generated during cutting. Use

wear- retardant cores.

Arbor hole out of round.

Collars/flanges are not properly

tightened, permitting blade to ro-

tate or vibrate on the shaft. Make

certain the blade is mounted on

the proper shaft nut with a wrench to make

certain that the blade is secure. Clean collars/

flanges;

Collars/flanges are worn or dirty. Blade is not

properly mounted. Make sure they are not

worn. Tighten arbor nut. Make sure the pin

whole slides over drive pin.

Blade worn out of round.

Shaft bearings are worn. Install

new blade shaft bearings or

blade shaft , as required.

Surges occur because engine is

not properly tuned. Tune engine according to

manufacturer’s manual.

Blade arbor hole is damaged from incorrectly

mounting the blade. If core is worn or arbor

hole damaged, DO NOT USE. Contact blade

manufacturer.

Bond/matrix is too hard for material. Replace

worn shaft or mounting arbor bushing.

Blade is slipping, wearing one half of blade

more than other. Make certain that drive pin is

functioning. Tighten spindle nut.

TECHNICAL DATA

POWER

ARBOR SIZE

MAX CUTTING DEPTH

BLADE CAPACITY

FUEL CAPACITY

WEIGHT

13 HP (9,6 kW)

1" (25,4 mm)

14,5 cm (5,7")

14''(35 cm)-20''(50 cm)

6,5 L

134 kg (295,4 lb)

CCO820 manual.indd 15

17/10/17 10:00