15

E N G L I S H •

User’s manual

1

2

3

4

5

operation of the power tool. If it is damaged,

have it repaired before using. Many accidents

are caused by poorly maintained power tools.

• Check for misalignment or bonding of mov-

ing parts, breakage parts, and any other condi-

tion that may affect the tools operation. If you

find a damaged tool, take it to service before

use it.

• Use only accessories that are recommended

by the manufacturer of your model. Suitable

accessories for one tool, may become hazard-

ous when are used on another tool.

• Do not alter or misuse the tool. These tools

have been built by precision. Any alteration or

modification not specified is misuse and may

result in a dangerous condition.

• Is recommendable to use a safety device suit-

able, such a thermal and diferential switch

when you are using an electric equipment.

REPAIR AND SERVICE

• Tool service must be perfomed only by quali-

fied repair personnel. Service or maintenance

performed by unqualified personnel could re-

sult in a risk of injury.

• When tool service is required, use only identi-

cal replacement parts and follow the instruc-

tions from Maintenance Section in this manual.

The use of unauthorized parts or failure to fol-

low Maintenance Instructions may cause a risk

of electric shock or injury.

SPECIFIC SAFETY RULES

DANGER !

INTAKE AIR. Can contain carbon monoxide or

other contaminants. Will cause serious injury

or death. URREA air compressors are not de-

signed, intended or approved for breathing air.

Compressed air should not be used for breath-

ing air applications unless treated in accor-

dance with all applicable codes and regula-

tions.

WARNING: HAZARDOUS VOLTAGE. Can

cause serious injury or death. Disconnect power

and bleed pressure from the tank before ser-

vicing. Lockout/Tagout machine. Compressor

must be connected to properly grounded cir-

cuit. Do not operate compressor in wet condi-

tions. Store indoors.

MOVING PARTS. Can cause serious injury. Do

not operate with guards removed. Machine

may start automatically. Disconnect power be-

fore servicing. Lockout/Tagout machine.

HOT SURFACES. Can cause serious injury. Do

not touch. Allow to cool before servicing. Do

not touch hot compressor or tubing.

HIGH PRESSURE AIR. Bypassing, modifying or

removing safety/relief valves can cause seri-

ous injury or death. Do not bypass, modify or

remove safety/relief valves. Do not direct air

stream at body. Rusted tanks can cause explo-

sion and severe injury or death. Drain tank

daily or after each use. Drain valve located at

bottom of tank.

CAUTION: RISK OF BURSTING. Use only

suitable air handling parts acceptable for pres-

sure of not less than the maximum allowable

working pressure of the machine.

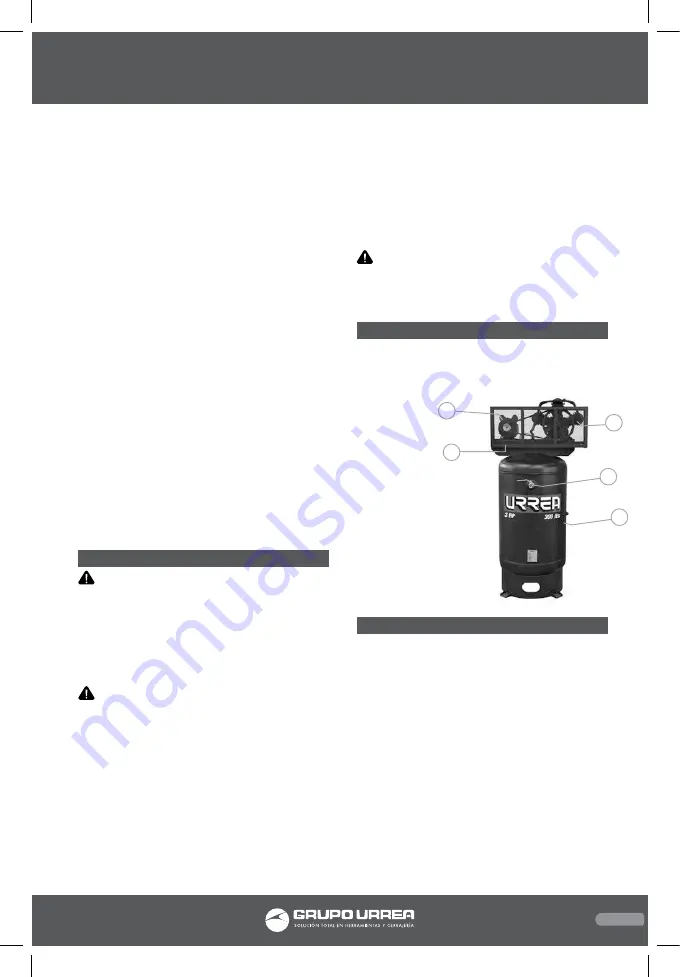

FEATURES

KNOW YOUR TOOL

Before attempting to use this product, become

familiar with all of its operating features and

safety requirements.

1. ENGINE.

2. HEAD.

3. 300 L TANK.

4. BALL VALVE. ?

5. PROTECTIVE GUARD.

INSTALLATION & OPERATION

APPLICATIONS

URREA’s standard one and two-stage lubri-

cated air compressors are single-acting, air-

cooled machines. Typical compressors are fur-

nished as compact, self-contained, air receiver

tank mounted units that are automatically

regulated and driven by an electric motor. An

air-cooled aftercooler, low oil level shutdown

switch and automatic drain valve are among

the optional accessories that can be furnished.

Bare compressor pumps and baseplate-mount-

ed units are also available. These compressors

may be used for a variety of compressed air

application up to 175 PSI. Application of these

compressors as either a primary or supplemen-

tary source of air is virtually unlimited in in-

dustrial plants, service stations and auto repair

shops.

COMP9303 manual.indd 15

23/06/15 14:26