19

E N G L I S H •

User’s manual

6 months / 1000 hrs of operation:

• Replace oil filter and change lubricant (if nec-

essary) on pressure lubricated modles.

12 months / 2000 hrs of operation:

• Change synthetic lubricant while crankcase

is warm.

• Replace filter element.

FILTER INSPECTION & CLEANING

1. Loosen the clamps se-

curing the filter housing

to its base.

2. Remove the filter hous-

ing and withdraw the old

filter element.

Clean the element with a jet of air or vacuum.

3. Replace the filter element and housing.

OIL CHANGE

1. Remove the oil drain plug and allow the lu-

bricant to drain into a suitable container.

2. Replace the oil drain plug.

3. Follow the filling procedures in INSTALLA-

TION section.

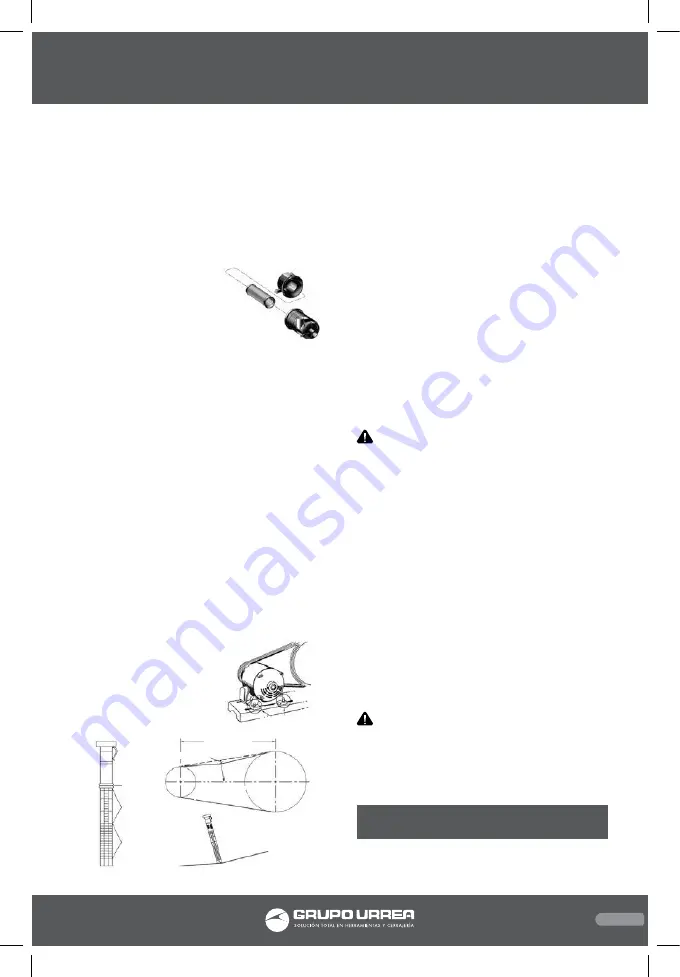

BELT ADJUSTMENT

CHECKING BELT TENSION. Check belt tension

should be occasionally, especially if looseness

is suspected. New belts must also be properly

tensioned upon installation.

TENSIONING BELTS

Belt tensioning can be achieved by loosening

the motor anchor screws, pushing the motor

away from the pump, and retightening the

motor anchor screws. Some units are equipped

with a belt tensioning bolt that, when turned,

pulls the motor away from the pump.

Otherwise, the motor can

be easily moved by placing

a prying tool beneath it.

A commercially available

spreader or other belt ten-

sioning device can also be

helpful.

Follow the procedures outlined below to cor-

rectly set and measure tension.

1. Measure the span length (t) of the drive.

2. Determine the amount of deflection (in

inches) required to measure deflection force

(in pounds) by multiplying the span length (t)

by 1/64. For example, a 32” span length multi-

plied by 1/64 equals 1/2” of deflection required

to measure deflection force.

3. Lay a straight edge across the top outer sur-

face of the belt drive from pulley to sheave.

4. At the center of the span, perpendicular to

the belt, apply pressure to the outer surface of

the belt with a tension gauge. Force the belt

to the predetermined deflection calculated in

step 2. Compare the reading on the tension

gauge to the BELT TENSION TABLE in the DIA-

GRAMS & TABLES section.

Ensure the pulley and sheave are properly

aligned and the motor anchor screws are ad-

equately retightened prior to restarting the

compressor.

CAUTION: Improper pulley/sheave align-

ment and belt tension can result in motor over-

load, excessive vibration, and premature belt

and/or bearing failure.

TANK INSPECTION

The life of an air receiver tank is dependent

upon several factors including, but not limited

to, operating conditions, ambient environ-

ments, and the level of maintenance. The exact

effect of these factors on tank life is difficult

to predict; therefore, URREA recommends that

you schedule a certified tank inspection within

the first five years of compressor service. To ar-

range a tank inspection, contact your closest

service center.

If the tank has not been inspected within the

first 10 years of compressor service, the re-

ceiver must be taken out of service until it has

passed inspection. Tanks that fail to meet re-

quirements must be replaced.

WARNING: Failure to replace a rusted air

receiver tank could result in air receiver tank

rupture or explosion, which could cause sub-

stantial property damage, severe personal

injury, or death. Never modify or repair tank.

Obtain replacement from service center.

TROUBLE SHOOTING:

AIR COMPRESSOR

ABNORMAL PISTON, RING OR CYLINDER

WEAR:

ANCHOR BOLTS

BELT SPAN (t)

DIRECTION OF

FORCE APPLIED

DEFLECTION

O-RINGS

DEFLECTION

FORCE SCALE

DEFLECTION

DISTANCE

SCALE

COMP9303 manual.indd 19

23/06/15 14:26