11

E N G L I S H •

User's Manual

TECHNICAL DATA

FUMU16

POWER

0,65 kW

DISPLACEMENT

26 cc

TANK CAPACITY

16 L

FUEL MIX RATIO

25:1

FUEL TANK CAPACITY

0,88 L

MAXIMUM ENGINE SPEED

(5 000 - 8 000) r/min

FUMU20

POWER

0,65 kW

DISPLACEMENT

26 cc

TANK CAPACITY

20 L

FUEL MIX RATIO

25:1

FUEL TANK CAPACITY

0,6 L

MAXIMUM ENGINE SPEED

(5 000 - 8 000) r/min

ASSEMBLY AND OPERATION

INSTRUCTIONS

ASSEMBLY

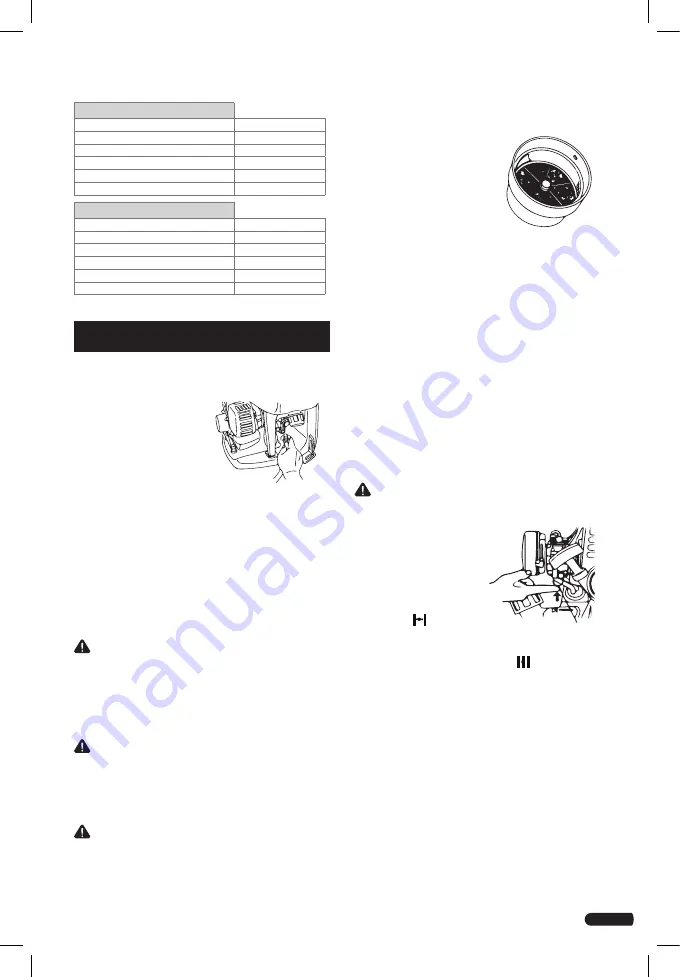

Attach the wide nozzle,

the nozzle pipe, the

ball cock in that order

to the spray hose and

connect the other end

of the hose to the spray

outlet.

PRE-OPERATION PREPARATION

FUELING

Place the engine on a level surface before add-

ing the fuel.

• Open the fuel filler flap and fill the tank with a

pre-mix of 25 parts of gasoline for 1 oil.

• Pour the mixture slowly to prevent it from

spilling, and thus allow air to escape from the

fuel tank.

• Close the lid firmly.

IMPORTANT: never fill the tank so the fuel

level rises into the filler neck. If the tank is over-

filled, heat may cause the fuel to expand and

overflow through the vents in the tank cap.

After refueling, make sure the fuel tank cap is

closed securely. If gasoline is spilled on the fuel

tank, wipe it off immediately.

WARNING: the engine exhaust of this prod-

uct contains chemicals known to cause cancer,

birth defects or other reproductive harm.

DILUTION OF CHEMICALS / CHARGINGTO THE

CHEMICAL TANK

CAUTION: Agricultural chemicals are ex-

tremely dangerous and must be handle with

care. Read the manual for specific chemical care-

fully before use.

Dissolve water dispersible powder in a separate

container before filing. Be sure not get foreign

material into the chemicals.

Always fill the chemi-

cal tank through the

strainer so that con-

taminants are not

mixed into the chemi-

cals.

Open the air bleed nozzle and bleed until the

chemical is draining out and then close the

nozzle securely. Before spraying the agrochemi-

cal, be sure to put on suitable protective cloth-

ing to protect yourself against contact with and

breathing it. Observe the following cautions for

safe operation:

a) Be sure to close the chemical tank cover se-

curely.

b) Check the spray hose and nozzle connections

to make sure there are no leakage.

c) Always stop the engine before refiling the

fuel tank or changing the nozzle.

d) When carrying a full chemical tank, be careful

not to lose your balance.

STARTING

IMPORTANT: When starting the engine, be

sure to fill the chemical tank with pure water or

chemical liquid. Never run the engine when the

chemical tank is empty.

• Pump the primer bulb

until fuel can be seen

flowing through the

fuel return line and

pull the choke lever to

full close “ “.

(During hot weather and when the engine is al-

ready warned up, the choke lever may be set to

either half open or full open “ “).

• Set the throttle lever to the middle speed posi-

tion (not necessarily maximum).

• The first starting attempt. Choke lever: Fully.

• Pull the recoil starter lightly 2-3 times.

• Pull the recoil starter strongly to the start the

engine.

• If the engine stops after a few revolutions,

set the choke to half open, and pull the recoil

starter rope strongly again to restart it.

NOTE: if the engine does not catch even after

the starter is pulled several times, set the choke

lever to full open and pull the starter rope. Be

sure not to pull the starter lever completely out.

After the engine starts, open the choke lever

Summary of Contents for FUMU16

Page 14: ...14 Notas Notes...

Page 15: ...15 Manual de usuario User s manual Notas Notes...