12

slowly. Move the throttle lever to the low-speed

side, and let the sprayer warm up for 2-3 min-

utes.

IMPORTANT: pulling the starter rope repeat-

edly with the choke on can choke the engine

and make starting difficult.

NOTICE: if you have choked the engine, re-

move the spark plug and gently pull the starting

rope to remove excess fuel; Then dry the spark

plug electrodes and put them back in the en-

gine.

OPERATING THE SPRAYER

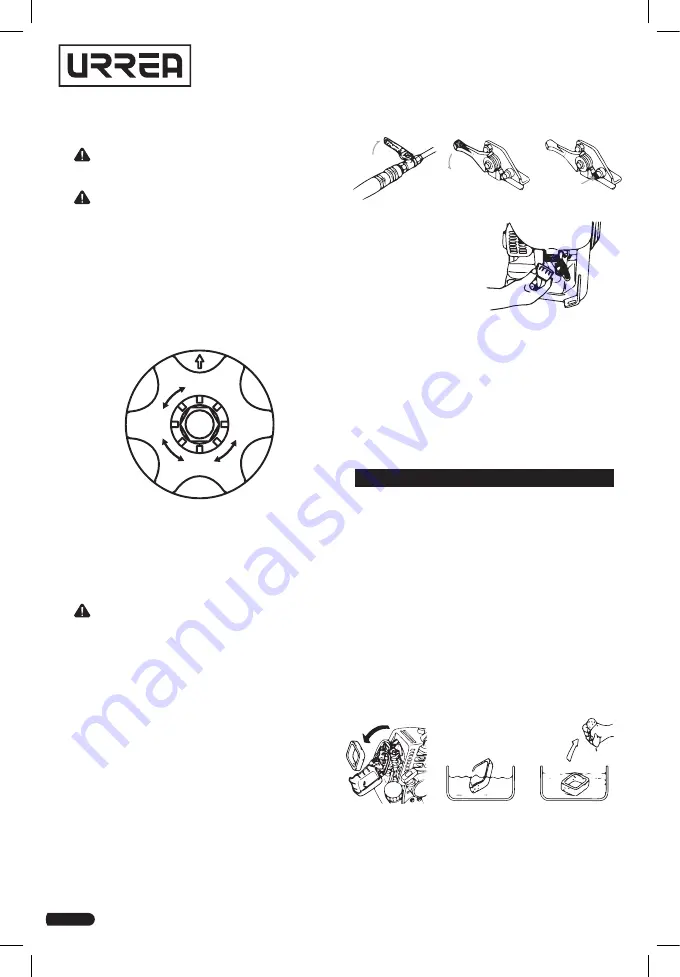

1. Turn the handle of the control valve, and set

it to the position for HERBICIDE, INSECTICIDE or

HIGH PRESSURE to match the pressure to the op-

erating conditions.

2. Check spraying conditions and the status of

the equipment, the shoulder the equipment

and set throttle lever to the high-speed posi-

tion.

3. When the nozzle cock is opened chemicals

will be atomized as they come out of the nozzle.

IMPORTANT: When the pressure control

valve handle is changed to INSECTICIDE or

HERBICIDE, with the throttle being fully open

at HIGH PRESSURE position of pressure control

valve handle, the engine speed will become too

high, corresponding to the extent of lowered

pressure. Therefor, use the equipment with the

throttle lever some what turned back from the

fully opened condition, when the equipment is

used at the position for INSECTICIDE or HERBI-

CIDE.

Be careful of the amount of fuel in the fuel tank

and refill when it becomes low.

STOPPING THE ENGINE

Temporary halt during operation.

a) Close the nozzle and return the throttle lever

to low speed.

b) Press the engine stop button.

c) After the engine stops, set the sprayer down

and close the fuel cock.

Stopping the sprayer

after completing spray-

ing

a) Remove the chemi-

cal tank drain cap and

drain of all the chemi-

cal.

b) Fill the chemical tank with clean eater, op-

erate the engine and clean the pump and hose

interior by spraying the clean water. Drain off

remaining water through the drain.

Star the engine at just less than high speed for

15-20 seconds to spray out the water in the

spray hose and nozzle. When water stops com-

ing from the nozzle, turn of the engine at once.

MAINTENANCE

AIR CLEANER SERVICE

Clean the air cleaner element every 20 hours.

• Remove the air cleaner cap from the air clean-

er case by removing the air cleaner cap screw.

• Remove the element from the air cleaner case.

• Wash the element in detergent and water, and

dry it thoroughly.

• Reinstall the element in the air cleaner case

and reinstall the air cleaner, and tighten the

screw.

NOTE: improper element cleaning can result in

engine damage. Do not use compressed air to

clean or dry element. Always clean element with

an approved high flash point solvent only. Never

use gasoline. Do not operate engine with air fil-

ter parts removed.

SPARK PLUG SERVICE

Every 50 hours of operation

• Take the spark plug cap with fingers, and pull

it up.

• Remove the spark plug by using a suitable

plug wrench.

STARTING

RE

HIGH PRESSURE

BI

HERB CIDE

INSECTICIDE

Close

Low

speed

Stop the

motor

Summary of Contents for FUMU16

Page 14: ...14 Notas Notes...

Page 15: ...15 Manual de usuario User s manual Notas Notes...