19

E N G L I S H •

User's Manual

line. When putting the filter back into the tank,

make sure that air comes to the front right cor-

ner. Also clean off dirt in the tank.

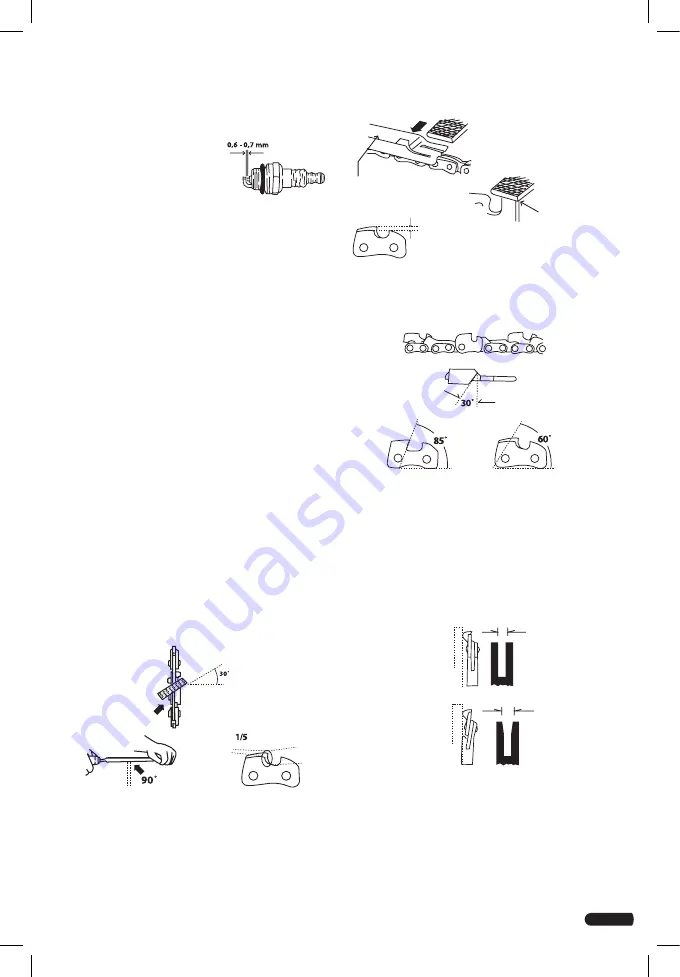

4. Spark plug.

Clean the

electrodes with a wire

brush and reset the gap to

0,65 mm as necessary.

5. Sprocket. Check for cracks and for excessive

wear interfering with the chain drive. If the

wear is considerable, replace it with new one.

Never fit a new chain on a worn sprocket, or a

worn chain on a new sprocket.

SAW MAINTENANCE

SAW CHAIN

- It is very important for smooth and safe opera-

tion to always keep the cutters sharp.

The cutters need to be sharpened when:

- Sawdust becomes powder-like.

- You need extra force to saw in.

- The cut path does not go straight.

- Vibration increases.

- Fuel consumption increases.

Cutter setting standards:

- Be sure to wear safety gloves.

Before filling:

- Make sure the saw chain is held securely.

- Make sure the engine is stopped

- Use a round file of proper size for the chain.

Chain type: 91 VG

File size: 5/32” (4,0 mm)

Place the file on the cutter and push straight

forward. Keep the file position as illustrated.

After each cutter has been filed, check the depth

gauge and file to the proper lever as illustrated.

NOTE: Be sure to round off the front edge to re-

duce the chance of kickback or tie-strap break-

age. Make sure every cutter has the same length

and eager angles as illustrated.

GUIDE BAR

- Reverse the bar occasionally to prevent partial

wear.

- The bar rail should always be square. Check for

wear of the bar rail. Apply a ruler to the bar and

the outside of a cutter. If a gap is observed be-

tween them, the rail is normal. Otherwise, the

bar rail is worn. Such a bar needs to be corrected

or replaced.

NOTE:

if you see any space between them, the

rail is fine, otherwise the bar is worn out. The

bar needs to be recalibrated or replaced.

Appropriate

gauge checker

Make the shoulder

round

Depth gauge

standard: 58

Regla

Con espacio

Sin espacio

Inclinación de la cadena

Cutter length

Filling angle

Side plate angle

Top plate cutting

angle