6

fluid volume to decrease and increases turn-

ing counterclockwise.

USE

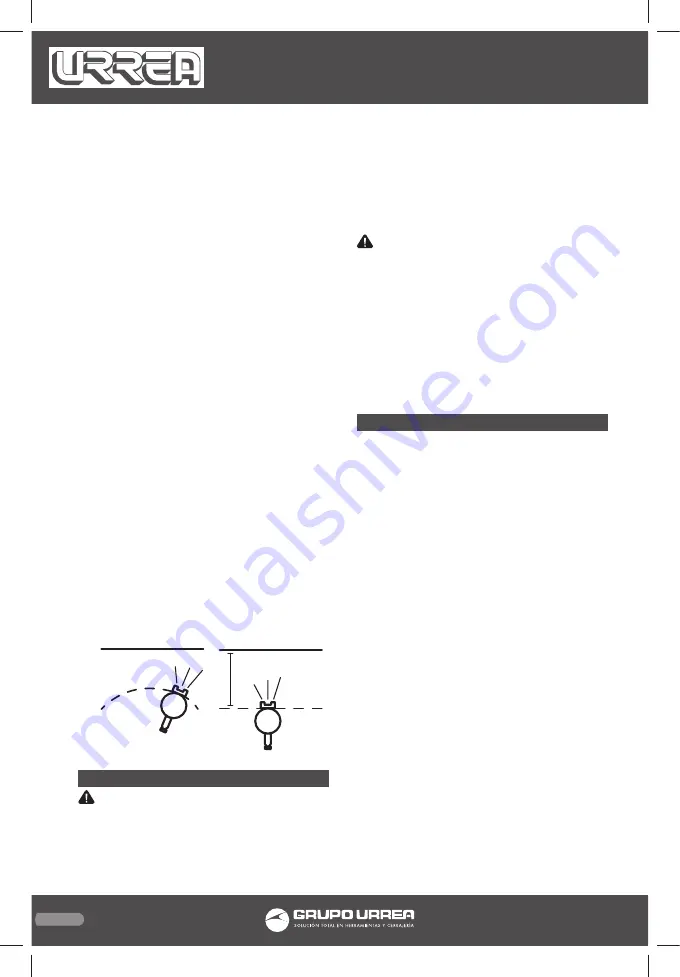

1. Start with the spray gun while maintaining

the right angle.

2. Keep a distance of 15-30 cm from the work

surface. Put the gun perpendicular to the area

to be sprayed and move in parallel direction

repeatedly. Note that stopping this move-

ment in the middle of the process causes a

buildup of paint, do not move from side to

side while painting the gun cause a build up

of paint in the center and an insufficient coat-

ing on the ends.

3. Start gun movement and then pull the trig-

ger. When you finish then release the trigger

and stop the movement of the gun. Thus com-

bining each stroke to the next without show-

ing irregularities.

4. The amount of paint to be applied may vary

depending on the speed of the route, the dis-

tance to the surface and the adjustment of

the fluid regulator.

5. Strokes overlap enough to obtain a uniform

layer.

NOTE: With two thin layers of paint and the

better the results will be less likely to run off

the paint against a single thick layer.

6. Use pieces of cardboard or other material

to protect the remaining surfaces of excess

paint during spraying.

MAINTENANCE

CAUTION: A LOW OR INCOMPLETE CLEAN-

ING CAN CAUSE FAULTS IN THE DISTRIBUTION

OF THE FAN.

1. Remove any remaining paint into another

container emptying the cup.

2. Disassemble the gun, making sure to remove

the needle (for the back of the gun) before re-

moving the nozzle to prevent damage to the

nozzle closure.

3. Clean all ducts which passes the painting.

Use the brush dipped in solvent to clean all

components of the gun.

WARNING: Never use metal or similar el-

ements that could damage the holes in the

nozzle and the container. Never completely

immerse the gun in solvent. Never use compo-

nents or parts that are not original.

STORAGE

1. When not using the gun turn left fluid regu-

lator to open, this will reduce the spring ten-

sion on the tip of the needle.

2. The gun must be clean and slightly oiled.

TROUBLESHOOTING

WRONG SPRAYING

Little fluid. Add more fluid.

Over tilting. Keep it upright.

Loss of fluid in connections. Tighten connec-

tions.

Lack of lubrication at nut and needle. Lubri-

cate.

Air outlet obstructed. Clean air outlet.

LOSS OF FLUID THROUGH DEPOSIT NUT

The cup connection is loose. Tighten.

The cup is damaged by the use or dry (lack of

lubrication). Replace the cup or lubricate with-

out using silicone oil.

THE FAN IS ARCHED

The nozzle is damaged or loose. Tighten or re-

place the nozzle.

Buildup of material on the air outlet. Remove

obstruction without using metal objects to

clean.

THE CENTER OF THE FAN IN TOO NARROW

Too little material or diluted. Regulate fluid

dissolution.

Air pressure is too high. Lower air pressure.

THE FAN IS TOO WIDE

Material too thick. Regulate fluid dissolution.

Air pressure too low. Raise the air pressure.

WRONG

At this

point the

coating

will be

scarce.

At this point the

coating will be

plentiful.

CORRECT

15 to 30 cm

The coating

is uniform.

PPG10-PPG17 manual.indd 6

17/11/15 5:32 p.m.