E N G L I S H

86

Temperature

Switches

•

•

•

Ignition System

Coils

•

•

Condensers

•

•

Connectors

•

•

•

Contact Set (points)

•

•

MAF Sensors

•

•

Magnetic Pickup

•

•

•

MAP/BP Sensors

•

•

O² Sensors

•

•

Starting System

Batteries

•

•

Connectors

•

•

Interlocks

•

Solenoids

•

•

•

Starters

•

•

•

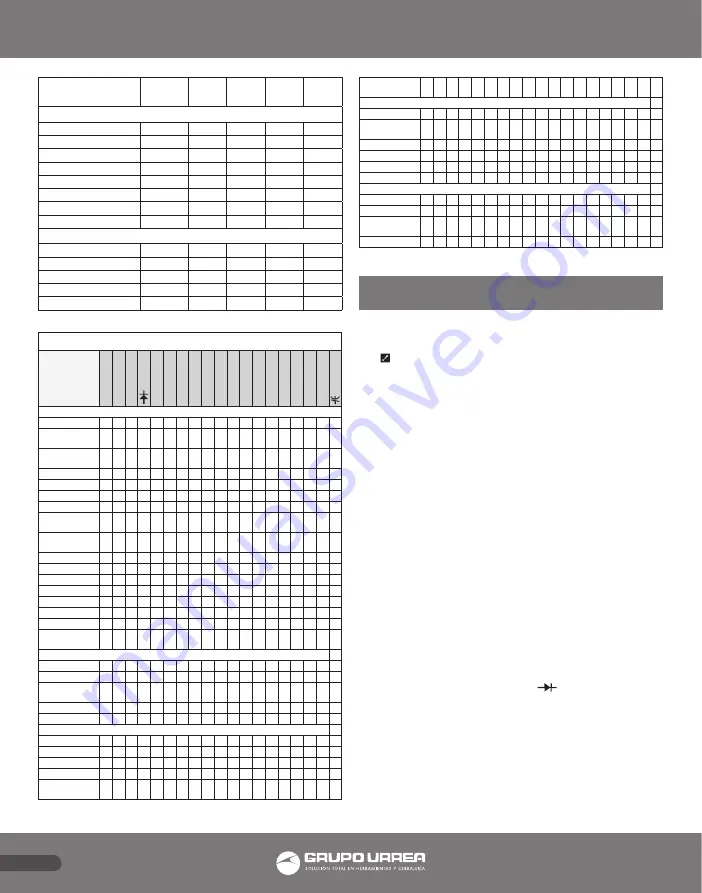

APPLICATIONS GUIDE

Amps DC*

Indicador Análogo

Continuidad

% Duty

Hz

Temperatur

e

Miliamps

Milivoltios

REC

Resistance

mS-Pulse

RPM

HOLD

Volts AC

Volts DC

REL

DWELL

Ignition / Engine

Coils

•

•

•

•

Computer Temp

Sensors

•

• •

• •

Condensers

(Capacitors)

•

•

•

•

•

Conectors

•

•

• • •

•

•

Contact set

• •

•

•

•

•

•

Distributor cap

•

•

Engine Speed

•

Feedback

Carburetors

• •

•

• •

•

Fuel injectors

(electronic)

•

• •

• •

•

•

Hall-Effect Sensors

•

• •

•

•

•

• •

Idle Air Motors

•

• • • •

• • •

•

Ignition Modules

•

•

•

•

MAF Sensor

•

•

•

Magnetic Pickups

• •

•

•

•

•

• •

MAP & BP Sensors

•

•

•

•

O2 Sensors

•

•

• •

Throttle Position

Sensors

•

• •

•

Starting system

Battery

•

•

•

•

Connectors

•

•

•

•

• •

Interlocks (neutral

safety switch)

•

• •

•

Solenoids

•

• • • • •

•

Starters

•

•

• •

•

• •

Cooling system

Connectors

•

• • •

•

•

Fan Motor

•

•

•

•

Radiator

•

•

Relays

•

• • •

•

Temperature

Sensors

•

• •

Temperature

Switches

•

•

• • • •

Charging System

Alternators

•

•

•

• • •

• •

Computarized

Regulated

•

•

•

•

•

•

Connectors

• •

•

Diodes (AC Ripple)

• •

•

Diode Rectifier

•

•

Regulators

• • •

• •

•

Body Electric

Compressor Clutch

•

•

• •

Lighting Circuits

•

•

Relay and Motor

Diodes

Transmissions

• •

* Used with a DC current clamp

7. MAINTENANCE AND REPLACEABLE

PARTS

General Maintenance

WARNING: REPAIRS OR SERVICING NOT COVERED IN THIS

MANUAL SHOULD ONLY BE PERFORMED BY QUALIFIED

PERSONNEL. TO AVOID ELECTRICAL SHOCK, DO NOT

SERVICE UNLESS YOU ARE QUALIFIED TO DO SO.

Periodically wipe the case with a damp cloth and

detergent; do not use abrasives or solvents. Water, dirt

or contamination in the A or mA μA input terminals

may harm this Meter. Calibrate this Meter once a year

to maintain its performance specifications.

Battery Replacement

The Meter uses a 9V battery (NEDA 1604 or IEC 6F22).

To replace the battery, remove the two screws of the

battery compartment from the back of the Meter and

lift off the cover of the compartment. Replace the

battery. Reattach the battery compartment to the

back of the Meter and reinstall the screws.

Fuse (s) Test

To test the internal fuses of this Meter:

1. Set the rotary switch to the “

“ position.

2. To test the F2 (15A, 600V) insert a test lead into the

or VΩRPM CAP input terminal and touch the probe to

the A input terminal.

The display should read about 0.000V. If the display

reads "OFL" (overflow), replace the fuse and test

again. If the display reads any other value, have this

Meter serviced.

Summary of Contents for UD88

Page 94: ...94 NOTAS NOTES ...

Page 95: ...95 NOTAS NOTES ...