25

ELECTRICAL POWER

The electrical installation must be per-

formed by a

qualified electrician

in accor-

dance with all applicable electrical codes.

Refer to Figure 18 and proceed as follows:

1.

Connect the outside power source

to

the terminals on top of the disconnect in

the starter enclosure. The hazard alert

label on the front of the starter enclosure

specifies proper voltage for this machine.

NOTE:

If voltage is not at least 95%

of specified voltage, the motor may

become overloaded during operation.

To maintain the watertight feature of

the starter enclosure, use “liquid tight” or

rigid conduit and appropriate fittings at

the power source entry point on the side

of the starter enclosure.

NOTE:

Additional holes added to

the starter enclosure may lessen the

water-tight features of the enclosure and

lead to electrical failures. Electrical com-

ponents that have failed due to water or

chemical contamination will not be cov-

ered under the warranty.

2.

Connect grounding conductor (green

or green and yellow striped wire)

to the

earth termination point located on back

panel inside the starter enclosure.

WARNING:

This machine can be

electrified with voltages dangerous to

life if not properly grounded! Always

maintain an earth ground to the earth

termination point on this machine.

3.

Connect the wiring

so that the impeller

turns

clockwise

. Rotation of impeller

motor shaft can be viewed by looking

through the opening in the fan shroud at

the rear of the impeller motor.

4.

Securely tighten screws

on the starter

enclosure door when finished with instal-

lation.

INSTALLATION

Electrical Power

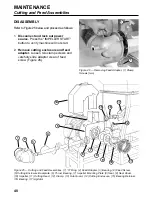

Figure 18 — Interior of starter enclosure (NEMA

components, top, CE components, bottom).

Connect outside power source to the terminals on

the power disconnect/lockout switch; connect

grounding conductor to the earth termination point.

(1) Circuit Breaker, (2) Power Source Entry Point,

(3) Earth Termination Point

1

1

2

3

3

2

Summary of Contents for COMITROL 2100

Page 2: ......

Page 28: ...Addendum A 26 This page intentionally left blank...

Page 84: ...6 This page intentionally left blank...

Page 94: ...16 This page intentionally left blank...

Page 95: ...17 GENERAL INFORMATION...

Page 101: ...23 INSTALLATION...

Page 104: ...26 This page intentionally left blank...

Page 110: ...32 This page intentionally left blank...

Page 131: ...53 PARTS...

Page 132: ...54 This page intentionally left blank...

Page 134: ...56 PARTS Tools See the Addendum for updated information...

Page 138: ...60 PARTS Agitator Feed Screw See the Addendum for updated information...

Page 146: ...PARTS Motor and Drive Parts 68 See the Addendum for updated information...

Page 148: ...PARTS Electrical Assembly NEMA 70 See the Addendum for updated information...

Page 152: ...PARTS Electrical Assembly CE compliant 74 See the Addendum for updated information...

Page 156: ...78 PARTS Electrical Assembly Switches See the Addendum for updated information...

Page 165: ......