Document Title:

MTP

®

Loopback Casing Installation

Document Number: AEN-1430, Rev. 1.0

8 of 17 THE USE OF SAFETY GLASSES FOR EYE PROTECTION IS RECOMMENDED

4.0

Terminating Fibers in MTP Connectors

4.1

MTP Connectors Compatible with Loopback Casing

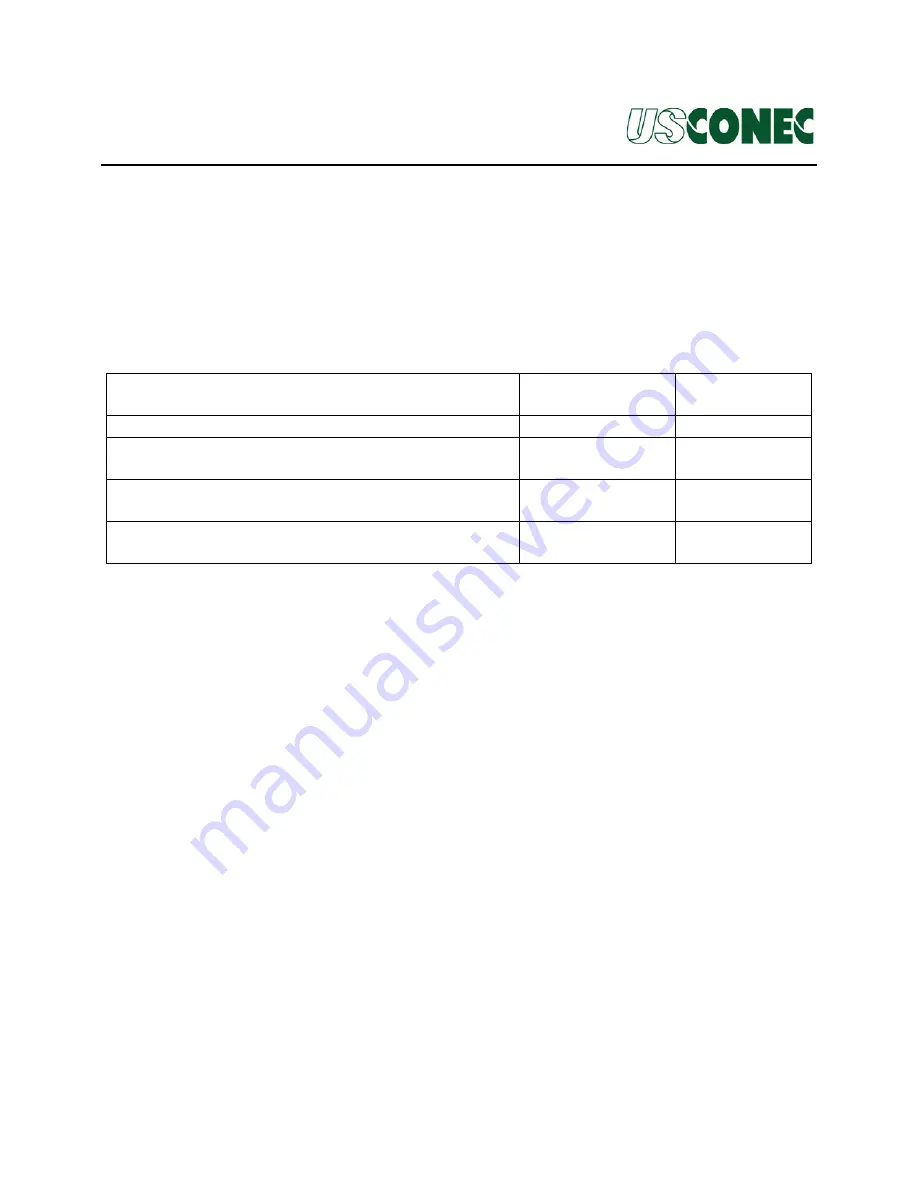

Refer to the latest US Conec customer drawings listed in Table 4.1 to select from

the connector kit and ferrule options that are compatible with the Loopback

Casing.

Table 4.1

Description

US Conec

Customer Drawing

Termination

AEN

Kit, MTP Connector, Ribbon, for One-row Loopback

C21467

AEN-1403

Kit, MTP Connector, High Spring Force, Ribbon, for

Two-row Loopback

C21490

AEN-1410

Kit, MTP-16™ Connector, Ribbon, for One-row and

Two-row Loopback

C21531

AEN-1424

Assembly, Ferrule and Boot, One-row and Two-row

Loopback

C7593

N/A

Note:

The two-piece, round spring push is also compatible with the Loopback Casing.

4.2

MTP Termination AEN

The following steps will refer to the corresponding MTP termination AEN listed

in Table 4.1 for additional instructions, materials, and equipment to strip, cleave,

and terminate the fibers in a ferrule and install the connector hardware.

Note:

There is one major deviation from the instructions in the MTP termination

AEN when assembling a loopback device. During normal jumper cable

assembly, the connector hardware is slid onto the fiber ribbon first.

However, for a loopback termination, this is not possible. Therefore, the

spring push, spring, and ferrule boot will be installed after the ribbon has

been stripped and cleaved.

4.3a

One-row Loopback

For two-row loopback, follow Step 4.3b.