14

REVISION 1.0, 1-19-15

4. Make sure that all parts are clean and free from dirt. Examine the brine seal, and permeate tube for

nicks or cuts. Replace the cap O-rings or membrane brine seal if damaged.

5. Flow directions should be observed for installation of the membrane element into the pressure vessels.

REPLACING THE MEMBRANE ELEMENT:

WARNING:

THE BRINE SEAL MUST BE IN THE SAME POSITION AS IT WAS FOR FACTORY PRE-

INSTALLED MEMBRANE ELEMENT. THE BRINE SEAL IS A RUBBER SEAL THAT PRO-

TRUDES ON ONE SIDE OF THE MEMBRANE AND IS ALWAYS ON THE FEED SIDE OF

THE MEMBRANE ELEMENT. FOR L1 SERIES RO SYSTEMS THE BRINE SEAL SHOULD

BE ON THE RIGHT SIDE OF THE MEMBRANE HOUSING.

BRINE

SEAL

Summary of Contents for L1-200

Page 1: ...1 REVISION 1 0 1 19 15 US Water Systems 300 GPD Premium Wall Mount Light Commercial RO System...

Page 9: ...9 REVISION 1 0 1 19 15...

Page 10: ...10 REVISION 1 0 1 19 15...

Page 11: ...11 REVISION 1 0 1 19 15...

Page 12: ...12 REVISION 1 0 1 19 15 SYSTEM IDENTIFICATION...

Page 17: ...17 REVISION 1 0 1 19 15 SPECIFICATIONS...

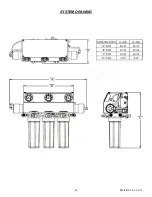

Page 24: ...24 REVISION 1 0 1 19 15 SYSTEM DRAWING...

Page 25: ...25 REVISION 1 0 1 19 15 L1 300 FLOW DIAGRAM...

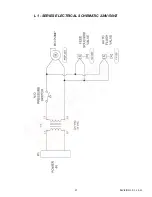

Page 26: ...26 REVISION 1 0 1 19 15 L1 SERIES ELECTRICAL SCHEMATIC 110V 60HZ...

Page 27: ...27 REVISION 1 0 1 19 15 L1 SERIES ELECTRICAL SCHEMATIC 220V 50HZ...