EN

EXTREMELY IMPORTANT: Read these safety instructions carefully in addition to the instructions for use, operation and maintenance.

This jack has been designed for use in the elevation of cars and lorries, although it may also be used in other applications, provided that the manufacturer’s

instructions reflected in this manual are complied with.

Any other application, beyond the conditions established for use of this jack will be considered inappropriate.

Handle the jack correctly and ensure that all parts are in good condition prior to its use.

Only authorised persons should operate the jack having read carefully and understood the contents of this manual.

Do not modify the jack in any way.

Non-compliance with these rules may result in injury or damage to the user, the jack or the load to be lifted.

The manufacturer accepts no responsibility for the improper use of the jack.

1. SAFETY INSTRUCTIONS

The owner and/or operator shall have an understanding of the product, its operating characteristics, and safety operating instructions before operating it.

Safety information shall be understood:

1.1 Study, understand and follow all instructions before operating this device.

1.2 Do not exceed rated capacity.

1.3 Support the vehicle with appropriate means immediately after lifting.

1.4 Lift only on areas of the vehicle as specified by the vehicle manufacturer.

1.5 No alterations shall be made to this product.

1.6 Only attachments and/or adapters applied by the manufacturer shall be used.

1.7 Visual inspection shall be made before each use by checking for abnormal conditions, such as cracked welds, leaks, and damaged, loose, or missing

parts.

1.8 It shall be the responsibility of the employer to ensure that applicable personal protective equipment (PPE) complies with applicable local safety codes.

1.9 Any product that appears to be damaged in any way, is found to be worn, or operates abnormally SHALL BE REMOVED FROM SERVICE UNTIL

REPAIRED OR REPLACED.

1.10 The jack should be supported on a solid, level and horizontal surface which is well illuminated and free of obstructions. Never stand the jack on a

surface which may sink.

1.11 Ensure that there are no persons inside the vehicle to be lifted. Switch off the engine and apply the brake. Ensure the vehicle or element to be lifted

against any type of sliding. Use chocks if appropriate (1). Do not enter the vehicle or start the engine whilst it is supported on the jack or appropriate

stands.

1.12 During raising and lowering of the load, all precautions should be taken to avoid movement of the vehicle load. Traffic may cause the raised vehicle to

rock during roadside use of the jack.

1.13 The jack should be positioned so as to avoid the need for the user to introduce any part of his/her body underneath the vehicle. Never work under a

raised vehicle without previously supporting it with mechanical stands (2) or other appropriate methods.

1.14 It is necessary for the operator to be able to observe the lifting device and the load during all movements. In the presence of dangerous conditions,

such as movement of the vehicle, etc, the lifting process must be interrupted.

1.15 Ensure that there are no persons or obstructions underneath the vehicle prior to lowering.

1.16 As an additional safety measure against overload, the jack is fitted with an overload valve (optional in models of 2t to 5t) set at the factory and

which should not be adjusted under any circumstances.

Failure to heed these markings may result in personal injury and/or property damage.

2. USE AND OPERATION

Important:

Prior to lifting the load, ensure that all of the aforementioned safety instructions are followed.

2.1 The extension screw of the jacks, if fitted, complements their stroke. It is advisable not to fully extend it.

2.2 For lifting, fully close the release valve and move the handle up and down using the full stroke range of the piston for greater speed.

2.3 For lowering, slowly turn the release valve in an anti-clockwise direction using the handle, ensuring that there are no persons or obstacles under the

vehicle to be lowered. The lowering speed is controlled by adjusting the release valve.

2.4 If the jack is subjected to a load greater than the nominal set, it has an overload valve (optional 2t to 5t) rated at 0 + 15% from the nominal value to

prevent the vehicle continue lifting.

2.5 Our jack may be used in a horizontal position provided that the pump is located on the lower side.

2.6

Important.

Due to the characteristics of telescopic jacks, a residue of oil may be observed in some of the pistons.

This is totally normal and is part of the correct operation of the jack.

2.7 To raise the jack,use narrow end of jack handle to tighten release valve clockwise (CW ) Insert handle into socket,and operate pump.

2.8 To lower the jack,SLOW LY open the release valve knob by turning it counter clockwise (CCW).

2.9 Only BTI bottle jack serie can be used in horizontal position (see drawing).

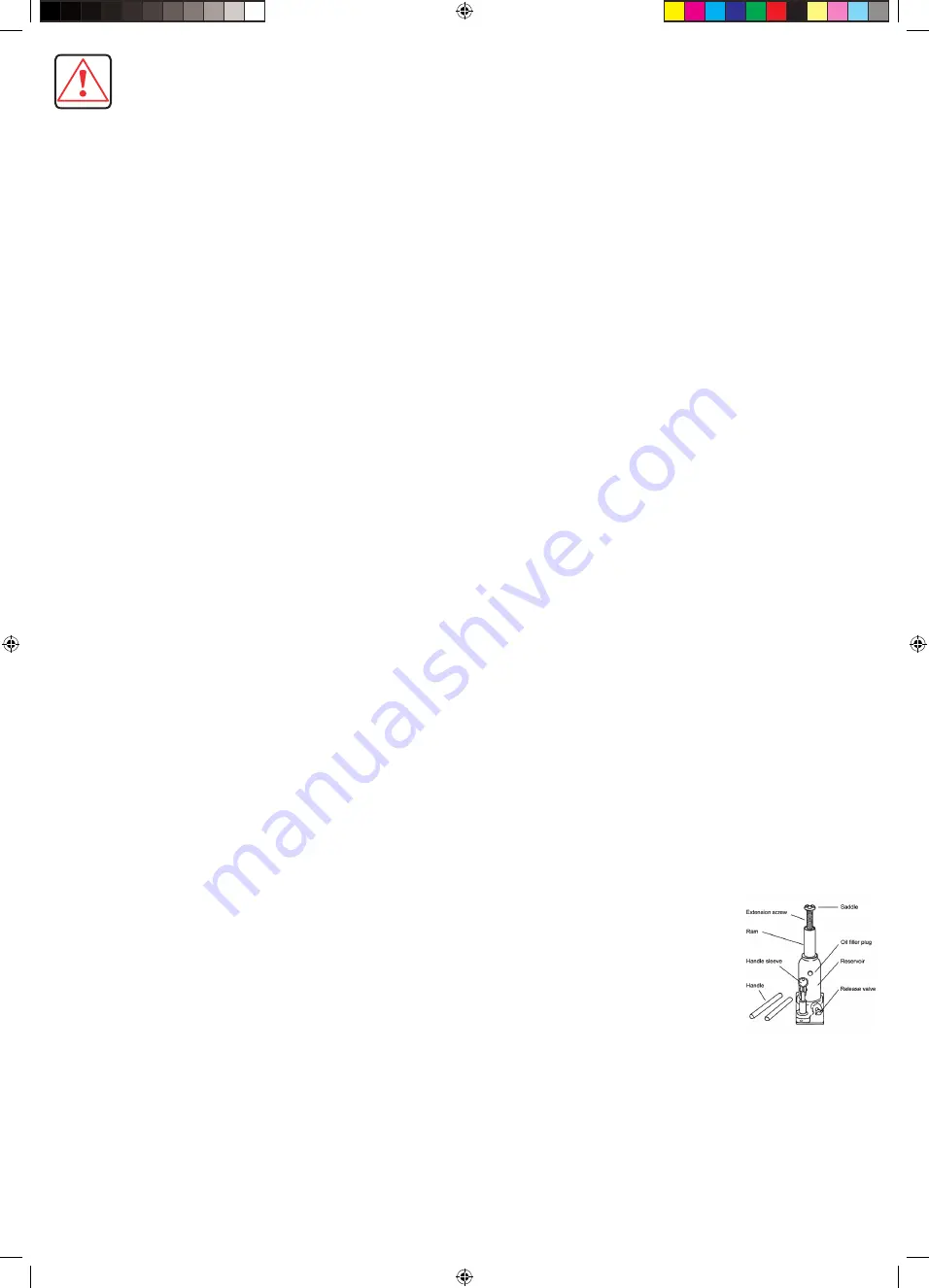

BLEEDING AIR FROM THE JACK

Air may accumulate within a bottle jack during shipment or after prolonged use; this air can cause the bottle jack to respond "weak".

Please use the steps below to bleed the air from the jack.

a - Use the notched end of the provided handle to engage and open the release valve counterclockwise for no more than 1/2 full turn.

b - Locate and remove the oil filter plug.

c - Insert the handle into the handle sleeve, fully extend and retract ram 6 to 8 times. This will help release and pressurized air which

may be trapped within the reservoir.

Note : Ensure the oil level is just below the oil filter plug hole. Reinstall the oil filter plug and close the release valve.

3. MAINTENANCE

Important:

Both the maintenance and repair of the jack may only be performed by qualified persons, who have sufficient knowledge of the hydraulic systems

used in these devices as a result of their training and experience.

3.1. Keep the jack clean and lubricate all moving parts at regular intervals, which must be clean and protected from aggressive conditions at all times.

3.2. Only original spare parts should be used.

3.3. Prior to each use, check for bent, broken, cracked or loose parts and solve the problem, if appropriate. If it is suspected that the jack has been

subjected to abnormal loads or has suffered any knocks, withdraw it from service until the problem has been rectified.

3.4. If the oil level needs to be checked or refilled, with the piston fully retracted, remove the filler plug and drain its contents into a container. With the jack

in a horizontal position, proceed to introduce the necessary volume as indicated for each model in these instructions.

Summary of Contents for 1951 B

Page 24: ...NOTE ...

Page 25: ...NOTE ...