16

17

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

Control Panel

Changing LaserPoint2 Speed

and Force

To set speed and force of the LaserPoint2, make sure you

are back in the “Home” screen with “Local” highlighted.

Press “Enter”. Use the up and down arrows to adjust the

speed and the left and right arrows to adjust the cutting

force. A typical cutting speed is 500mm/s, and a typical

cutting force is 100.

Reset

Select

Enter

Home Screen

LOCAL TEST COPY

SPD: 0mm/s PRS: 10g

Setting the Origin for

LaserPoint2

To set the Origin of where the LaserPoint2 cutter will

begin cutting from press the “Enter” button on “Local”

while on the Home Screen using the “Select” button to

highlight it if needed. This will enter the cutter into “Jog

Mode” where the left and right arrows of the control

pad adjust the position of the carriage and the up and

down arrows advance and retreate the media via the

feed rollers. Once you have your media and carriage

in position press the “Select” button, while in the Local

Screen, to move the cursor to “Current” then press

“Enter” and the origin is set.

Reset

Select

Enter

Local Screen

ORIGIN CURRENT ON

SPD: 0mm/s PRS: 10g

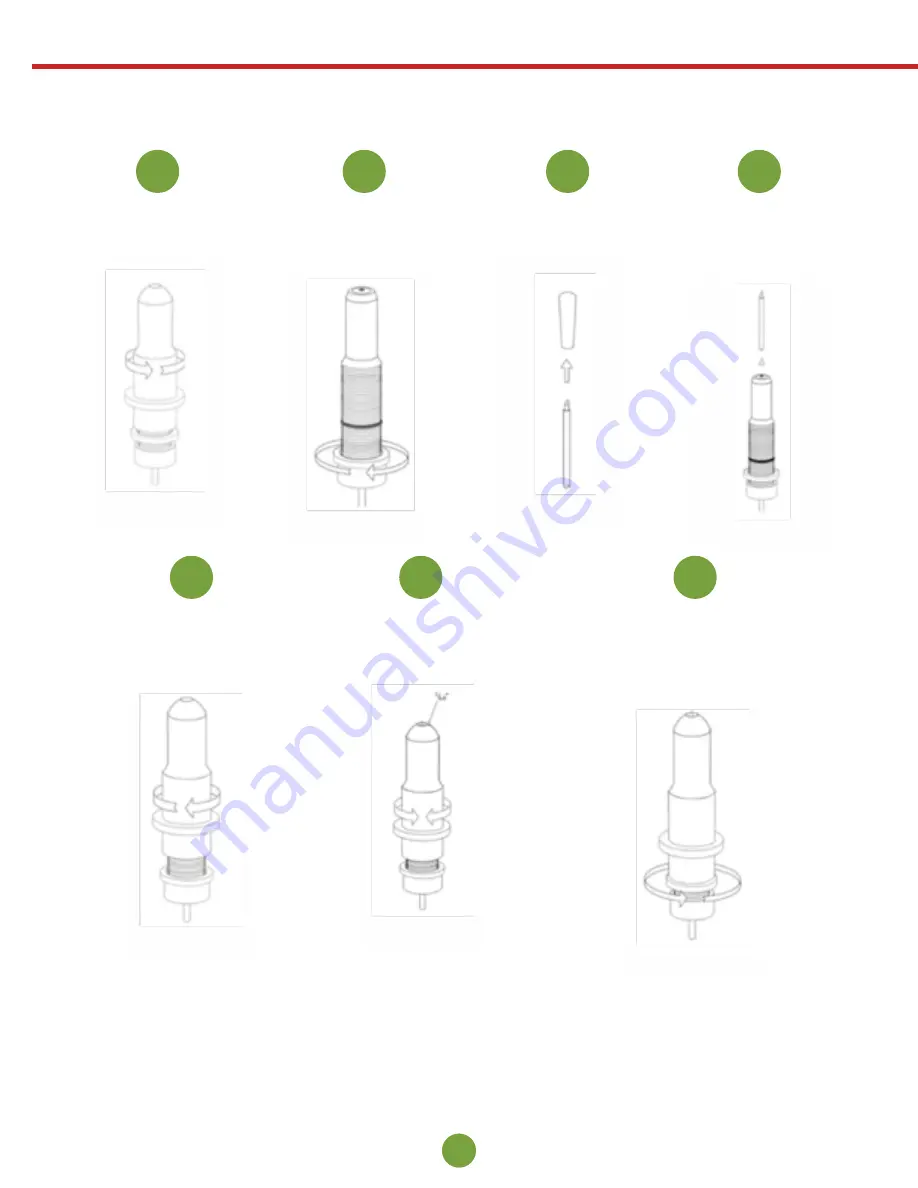

Blade Set Up

Unscrew the cap from the

Blade Carriage.

Screw the cap back onto

the Blade Carriage.

Adjust the carriage cap until the blade

is protruding approximately 1/64

th

of an

inch.

Adjust the Brass Ring until it fits snug

against the Cap. This will help keep

the cap in place during operation.

Set Brass Ring on Blade

Carriage to the fully down

position.

Remove the protective cover

from a new blade.

Insert the blade into the

top of the Blade Carriage.

1

5

7

6

2

3

4

Blades should be replaced every

6 months

. Your blade may need to be replaced

more often if you are cutting thicker material such as flock, glitter, or reflectives.

14

15